Method of combined mining caving face using false dipping after high drainage roadway treating gas in beginning mining

A fully-mechanized caving face and initial mining stage technology, which is applied in the field of fully mechanized caving face using pseudo-inclined high pumping roadway to control gas in the initial mining stage, which can solve problems such as difficult gas problems, high mining intensity, and gas exceeding the limit in the working face

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

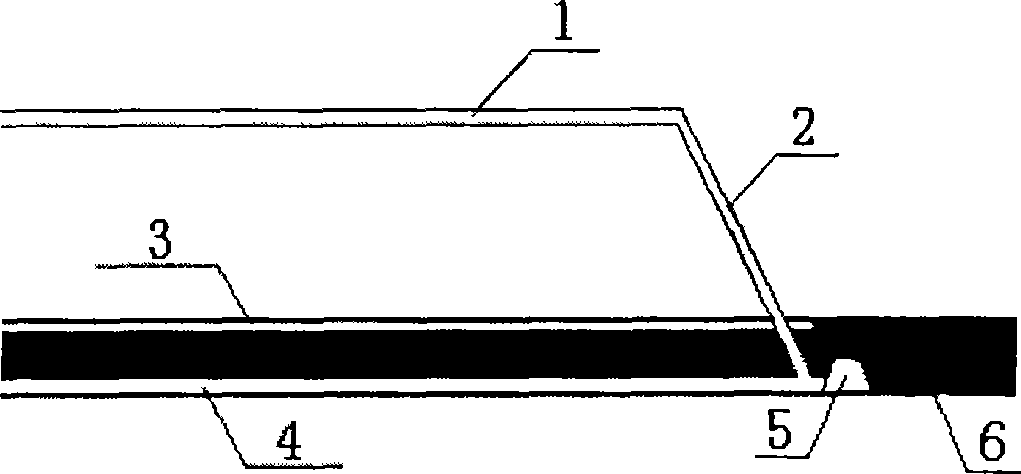

Image

Examples

Embodiment Construction

[0008] Below in conjunction with embodiment the present invention is described in further detail, as the main coal-bearing strata of the present invention are Carboniferous Taiyuan Formation and Permian Shanxi Formation in Yangquan mining area, the total area of mining area is 1105Km , geological reserves are 10.73 billion tons, and the total amount of coal-measure strata is The thickness is 180m, the total thickness of the coal seam is 13-15m, and the depth from the surface is 150-500m. The dip angle of the coal seam is generally 5-10 degrees. The mining area contains a total of 16 coal layers (numbered sequentially from top to bottom), all of which are anthracite with a high degree of metamorphism. The average thickness of the thick coal seam is 6.5m, and the occurrence is stable. The structure of the coal seam is complex, and there are three layers of rock interlayers. Thick coal seams are harder (f=2~3), and the sulfur content in coal seams is generally between 1.37% and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com