Electroacoustic transducer

An electro-acoustic conversion and fixed position technology, applied in the direction of electrical components, sensors, etc., can solve the problem of residual sound pressure reduction and achieve the effect of thinning and sufficient sound pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

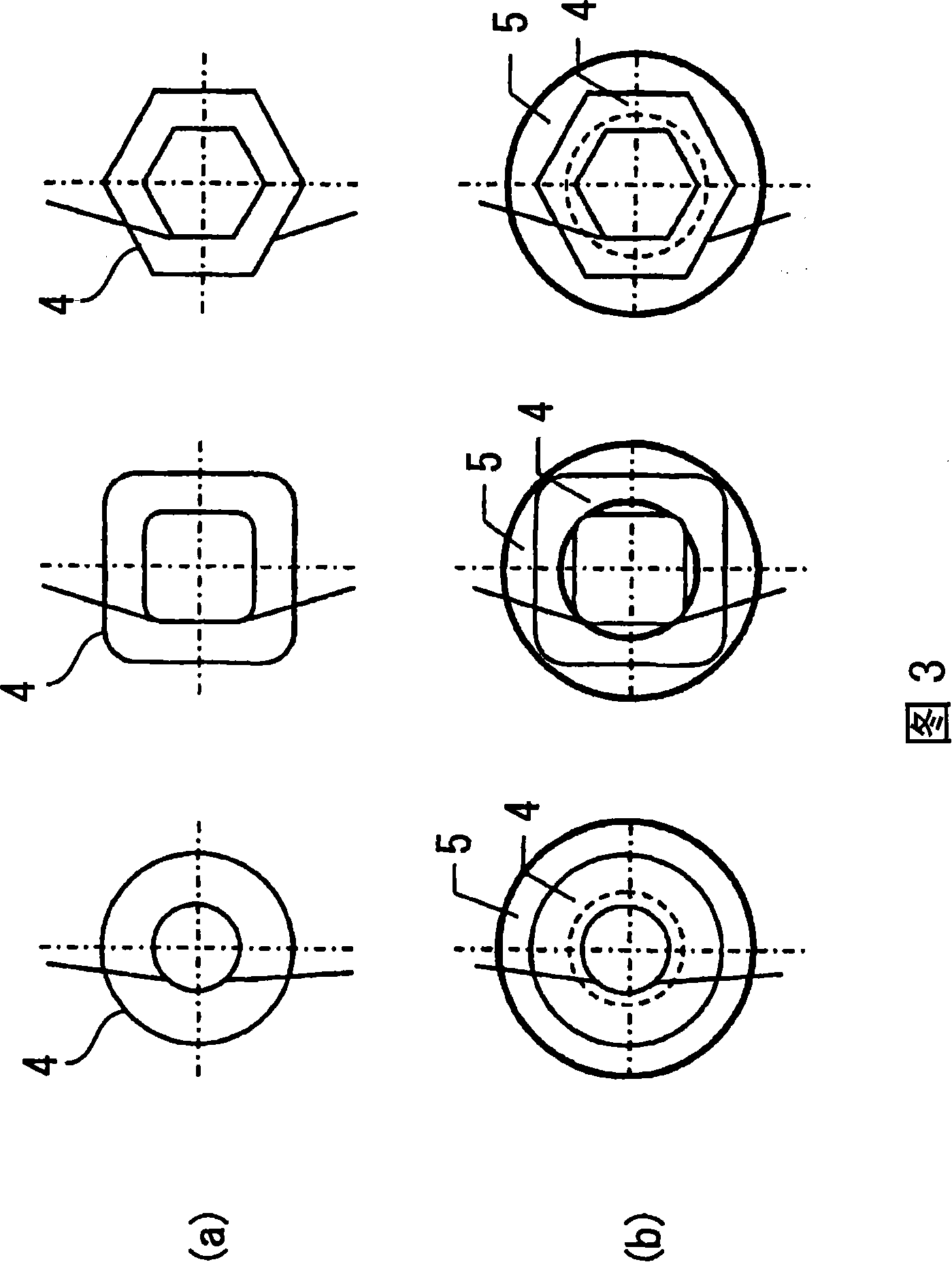

[0073] Such as figure 1 and figure 2 As shown, the electroacoustic transducer of the first embodiment related to the present invention is provided with a flat cylindrical frame 1, and a disc-shaped cover having a plurality of sound emitting holes 20 is mounted on the front opening of the frame 1. 2.

[0074] Such as figure 2 As shown, a disk-shaped vibrating plate 3 is provided inside the frame 1 , and the outer peripheral portion of the vibrating plate 3 is sandwiched between the frame 1 and the cover 2 . A flat cross-sectional coil 4 wound around the axis S on the vibration plate 3 is fixed to the back surface of the vibration plate 3 .

[0075] In addition, inside the frame 1, a predetermined gap is provided between the coil 4 and an annular outer magnet (outer magnet) 5 is fixed, and the central hole of the outer magnet 5 is equipped with a metal ring made of iron, permalloy (permalloy) or the like. A disk-shaped inner core (inner core) 6 formed of a ferromagnetic m...

no. 2 example

[0088] Such as Figure 6 Shown in (a), the electroacoustic transducer of the second embodiment related to the present invention, except that the central hole of the outer magnet 5 is equipped with a cylindrical inner magnet 51, other structures are the same as those of the electroacoustic transducer of the first embodiment same.

[0089] Inner magnet 51 such as Figure 6 As shown in (a), it is magnetized in the direction opposite to the outer magnet 5, and the lines of magnetic force emitted from the outer magnet 5 and the inner magnet 51 are as follows: Figure 12 As shown in (a), a loop is drawn on the inner peripheral surface side and the outer peripheral surface side of the outer magnet 5 , and the magnetic flux loop on the inner peripheral surface side acts on the coil 4 .

[0090] Here, since the inner magnet 51 having a polarity opposite to that of the outer magnet 5 is arranged in the central hole of the outer magnet 5, the magnetic flux loop on the inner peripheral su...

no. 3 example

[0102] Such as Figure 16 and Figure 17 As shown, the electroacoustic transducing device of the third embodiment related to the present invention is provided with a flat cylindrical frame 11 having an oblong or elliptical planar shape, and a plurality of sound emitting holes 20 are mounted on the front opening of the frame 11. A cover 21 having an oblong or elliptical planar shape.

[0103] Such as Figure 17 As shown, a vibrating plate 31 having an oblong or elliptical planar shape is provided inside the frame 11 , and the outer peripheral portion of the vibrating plate 31 is sandwiched between the frame 11 and the cover 21 . A flat cross-sectional coil 41 wound around the axis S on the vibration plate 31 is fixed to the back surface of the vibration plate 31 .

[0104] In addition, a pair of rectangular parallelepiped outer magnets 7, 7 are fixed with a prescribed gap between the frame 11 and the coil 41, and a strong magnet made of iron, permalloy, etc. is installed bet...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com