Bag-type dew dust remover

A dust collector and bag-type technology, applied in chemical instruments and methods, separation of dispersed particles, filtration of dispersed particles, etc., can solve the problems of airtight filter material, filter failure, and inability to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach 1

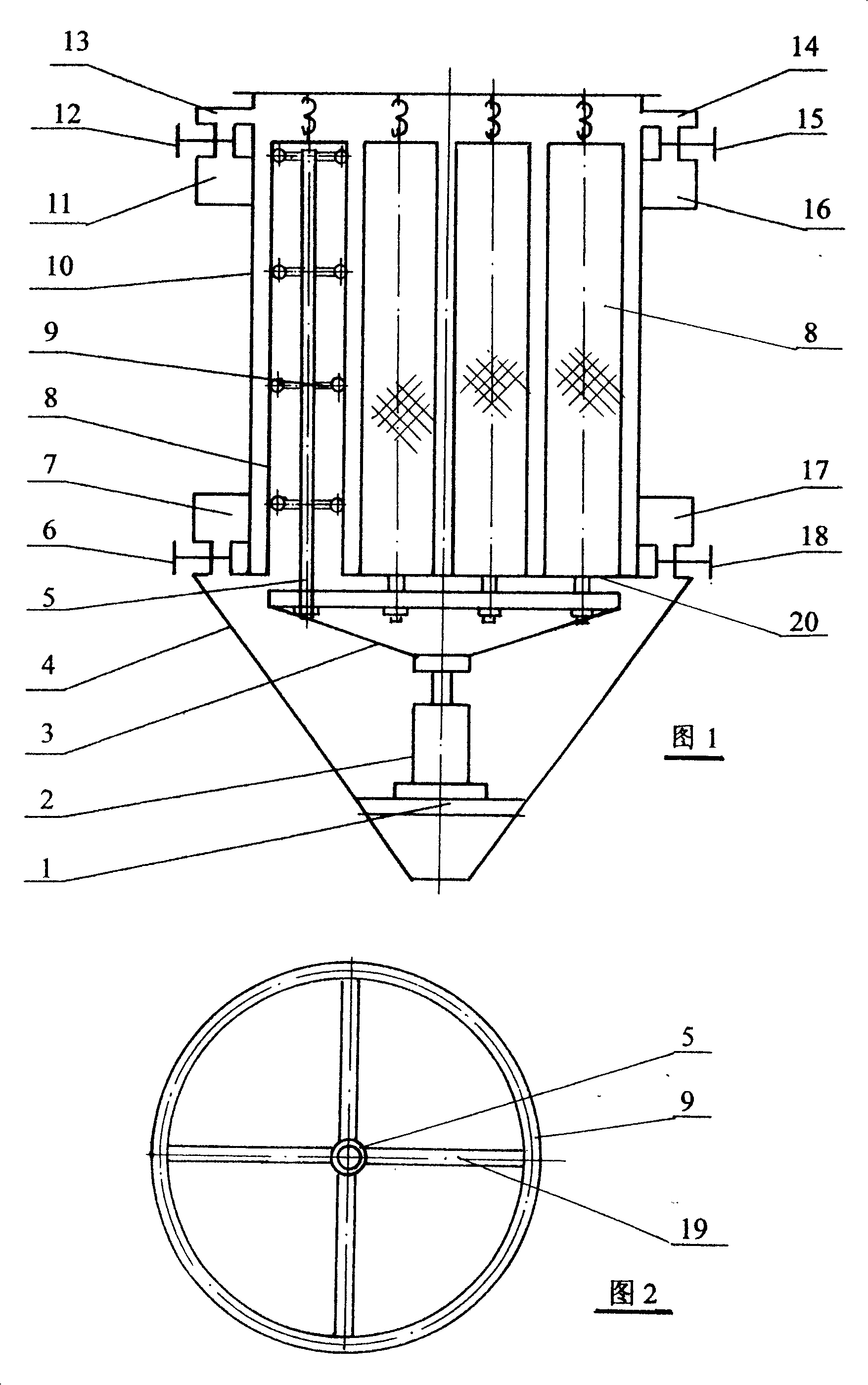

[0021] Specific embodiment of the present invention 1 referring to Fig. 1, Fig. 2, by main box body 10, flower board 20, lower end and flower board fix four rows of cloth bags 8, lower box body 4, air inlet pipe whose upper end is suspended on the top plate by springs 17. The air outlet pipe 16 and the anti-blow pipe 11 constitute the main body of the dust collector. The cloth bag 8 with a design diameter of 15cm and a length of 2m is equipped with 4 bags with an outer diameter of 14.6cm at an even interval of 50cm that can move up and down. The ash scraping ring 9 is made of a steel wire with a diameter of 0.4cm, and each ash scraping ring is fixedly connected to the ash scraping rod 5 at the center of the ash scraping ring 9 with 4 connecting bars 19, and each ash scraping rod The lower end of 5 extends into the lower box body 4, and is fixed on the support 3 that does not prevent the dust from falling with bolts. The support 3 is connected to the telescopic rod equipped with...

Embodiment approach 2

[0033] According to the filtering method, the bag filter is divided into two types: inner filter and outer filter. The structure of the outer filter dust collector has an additional upper box, and a skeleton is added inside the cloth bag. Scheme 1 is the inner filter type, and scheme 2 is the outer filter type. In this way, the dust is collected on the outer surface of the bag. The specific structure of this scheme 2 is shown in Fig. 6 and Fig. 7, and the difference with scheme 1 is: dust-scraping ring 9 is enclosed within the outside of cloth bag 8.

[0034] The outer diameter of the frame is designed to be 14cm (due to the contraction of the bag during dust removal in the external filter type, there must be a frame to support the bag), the diameter of the bag when it is bulging is 15cm, and the outer cover of the bag 8 with a length of 2m is evenly spaced. The internal diameter of 50cm is 14.6cm (skeleton outer diameter at this moment will be less than about 0.6cm of ash scr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com