Condensing and membrane separation combined type oil gas reclaiming technical technology

A process technology and membrane separation technology, applied in the field of oil and gas recovery, can solve problems such as high cost, high equipment material requirements, and complex process technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

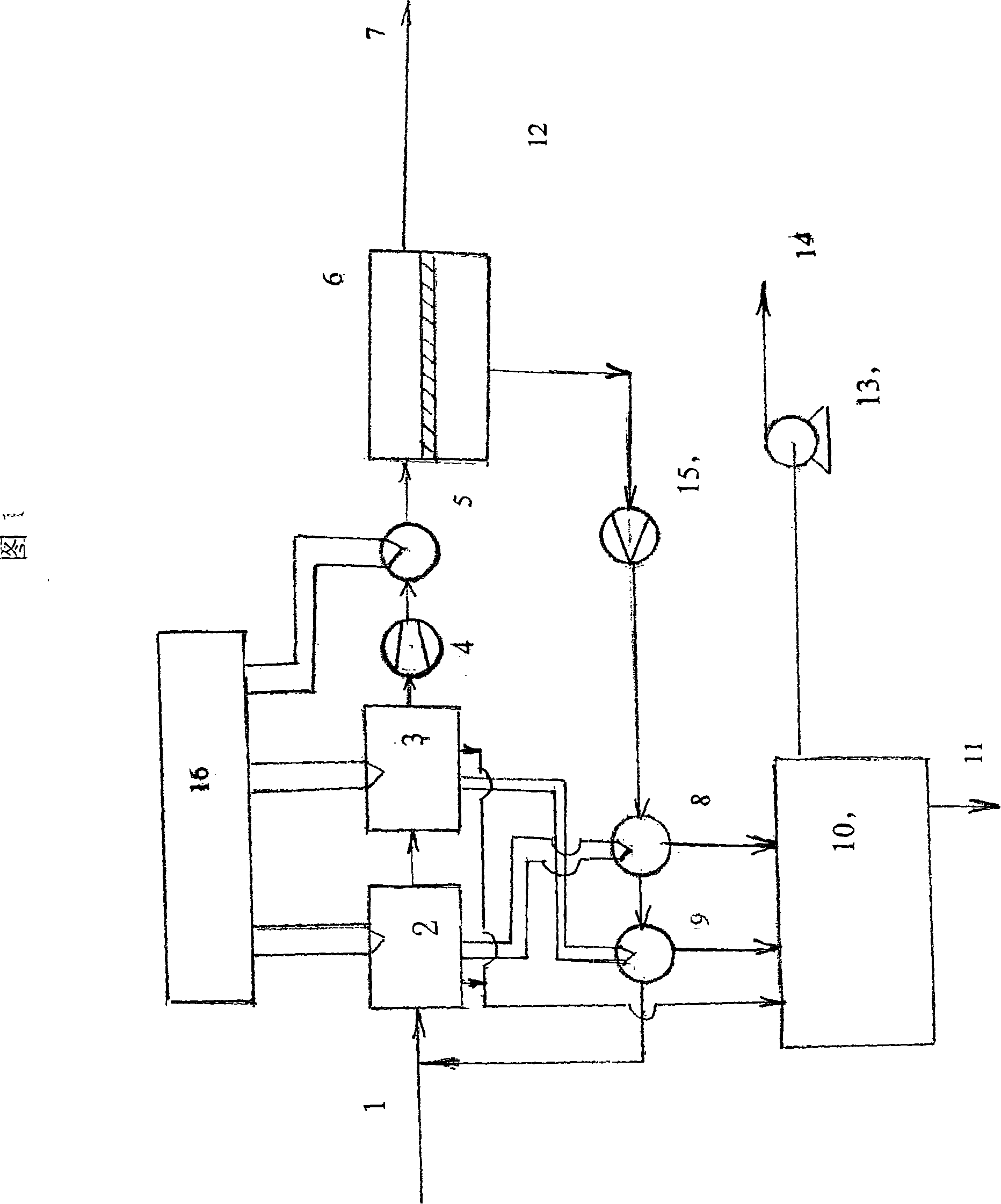

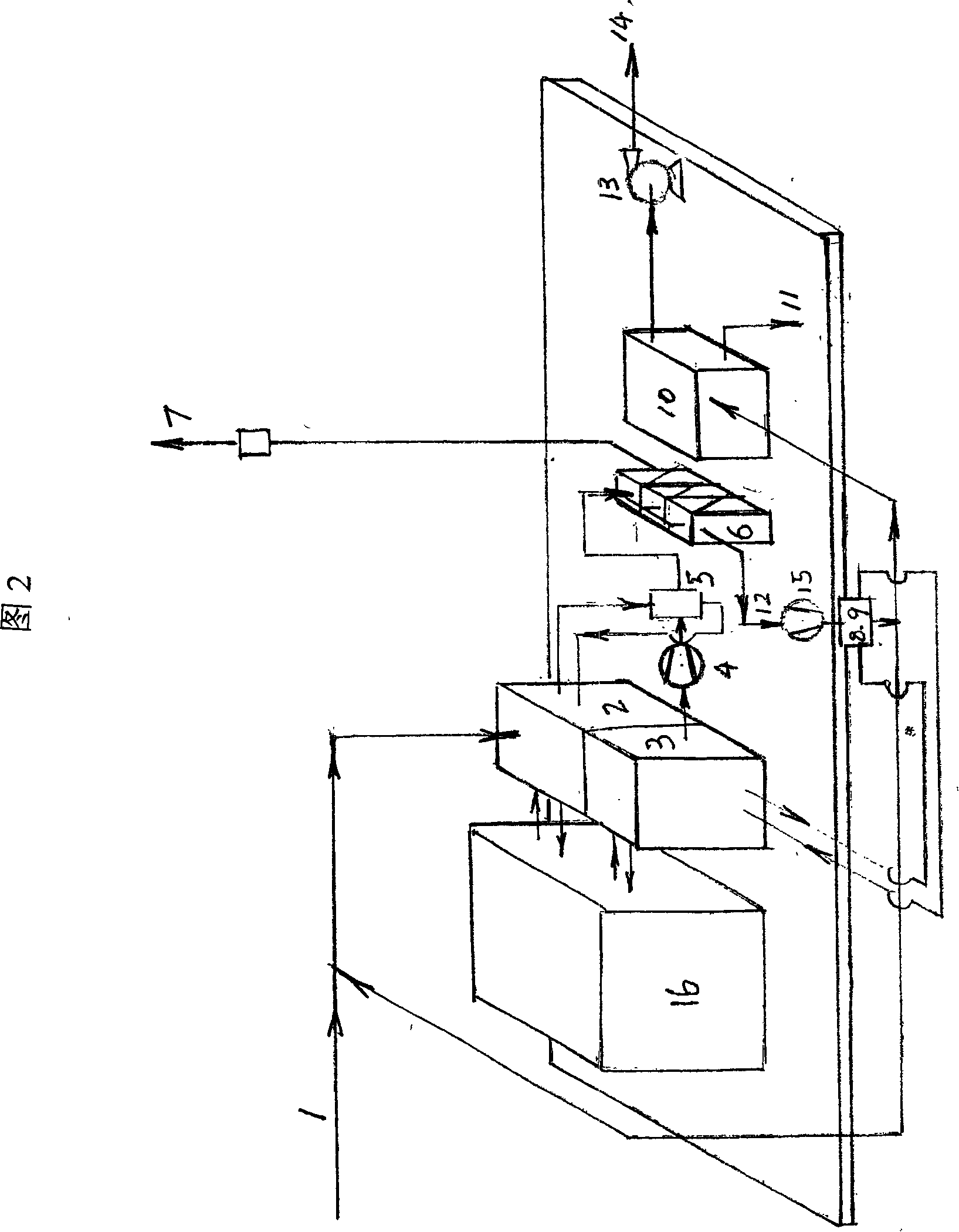

[0011] The condensation and membrane separation combined oil gas recovery process technology of the present invention can manufacture and install a modular condensation and membrane separation combined oil gas recovery device according to the process technology of the present invention.

[0012] The specific implementation method is:

[0013] 1. The user of the oil depot first proposes the composition of oil and gas, the processing capacity of oil and gas (M 3 / h) The process parameters are calculated by computer simulation.

[0014] 2. Design the size and specifications of the equipment according to the process parameters, and then manufacture them in the factory.

[0015] 3. The specific method of connection and installation between the equipment is: according to the process sequence of the attached drawing 1, connect the oil and gas pipeline 1 and the inlet of the pre-cooling box 2 with flanges, and connect the outlet pipeline of the pre-cooling box 2 and the inlet of the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com