Uniaxial micro-tensile test piece for thin film mechanical performance test

A micro-stretching and thin-film technology, which is applied in the field of uniaxial micro-tensile test pieces, can solve the problems of non-silicon materials that are not suitable for measuring large plastic deformation, are not suitable for routine operations, and the rigidity of the support beam is large, so as to achieve high yield. , high verticality, the effect of solving measurement errors

Inactive Publication Date: 2011-01-05

SHANGHAI JIAOTONG UNIV

View PDF0 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Its disadvantage is that it is not suitable for measuring non-silicon materials with large plastic deformation due to the high rigidity of the support beam of the micro-tensile sample.

And the whole test system must be placed in SEM or TEM for observation and measurement, which is not suitable for routine operation, and the application range is greatly limited

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

Embodiment 3

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Login to View More

Abstract

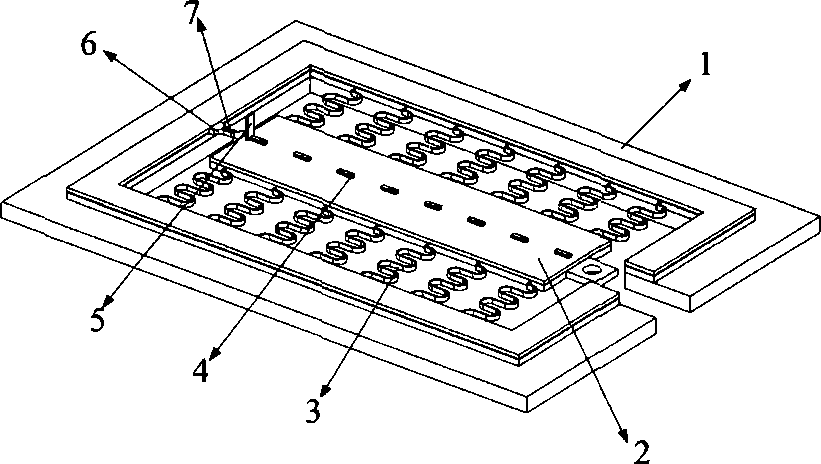

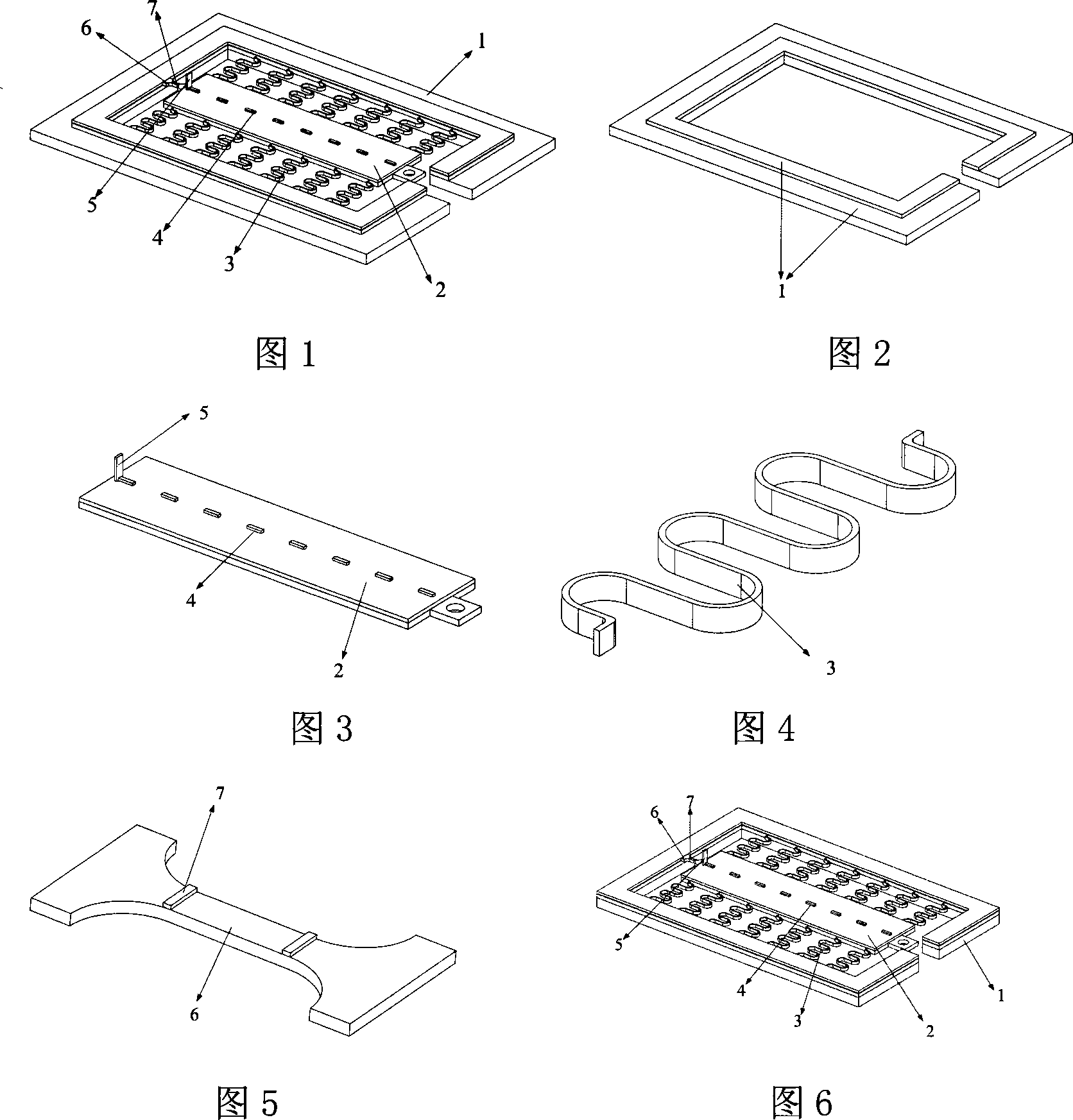

The single -shaft micro tensile test piece to test the film dynamic performance includes the U shpe supporting platform, movable platform, the snake supporting spring, centring marker, displacement marker. The snake supporting spring is connected with the U shape supporting platform and movable platform; the U shape supporting platform and movable platform are connected with two suspended ends ofthe film sample; the centring marker is on the top of the movable platform; the displacement marker is pasted to the tail to movable platform and near to the film sample. Compared to the present testpiece, the process is available, it has good repeatability and high yield; also it has avoided the test error generated by the supporting girder deformation in tension process. The test piece of invention is proper for the film micro dynamic performance test of single metal, alloy and compound material.

Description

Uniaxial Microtensile Specimen for Thin Film Mechanical Properties Test technical field The invention relates to a tensile test piece in the technical field of testing, in particular to a uniaxial micro-tensile test piece used for testing the mechanical properties of thin films. Background technique With the rapid development of micro-electromechanical systems, various thin-film materials are widely used in micro-devices. Since the structure of micro-devices is not a simple reduction in the size of traditional mechanical structures, when the size of the structure is reduced to the order of microns / nanometers, there will be obvious size effects. , leading to significant changes in the mechanical and physical properties of materials, so the microscopic mechanical properties of thin film materials are significantly different from the macroscopic mechanical properties of materials. The mechanical performance parameters measured by large-volume samples are far from meeting the d...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): G01N3/00G01N13/00

Inventor 汪红刘瑞丁桂甫李雪萍杨春生

Owner SHANGHAI JIAOTONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com