Anti-vibration brick

A technology of brick body and convex column, which is applied in the direction of earthquake resistance, building components, buildings, etc., can solve the problems of high requirements and poor earthquake resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

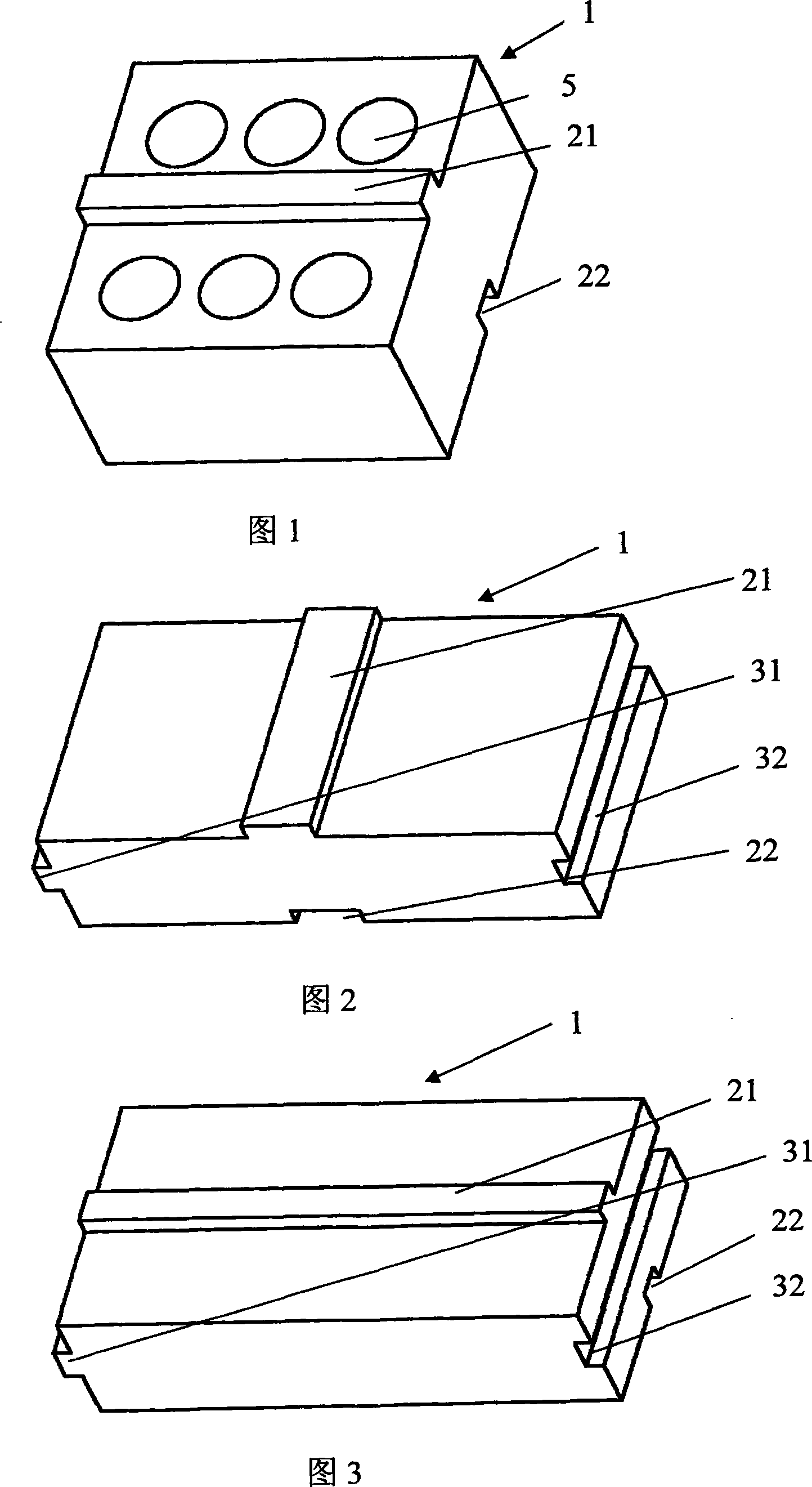

[0020] See Figure 1 for details. In the figure, 1 is a cube brick body, and there are via holes 5 running through the upper and lower planes of the brick body 1. Therefore, the entire brick body is a hollow structure, and a convex column 21 is arranged upward in the middle of the upper plane of the brick body. The convex column The shape of 21 is a cuboid; a groove 22 is arranged upwards in the middle position of the lower plane of the brick body, and the shape of the groove 22 is a cuboid; It is slightly smaller than the corresponding length, width and height of the groove 22, so the boss can be completely inserted into the groove of another brick. During construction, in the case of building walls upward, it is only necessary to always ensure that the convex column is placed in the groove, and the lower plane of the upper brick body is bonded to the upper plane of the lower brick body to form an integrated wall, achieving excellent Of course, the bricks between the upper and...

Embodiment 2

[0022] See Figure 2 for details. In the figure, 1 is a cuboid brick body, and the brick body 1 is a solid structure. A convex post 21 is arranged upwards in the middle of the upper plane of the brick body, and the shape of the convex post 21 is a cuboid; There is a groove 22, and the shape of the groove 22 is a cuboid; the direction of the protrusion 21 and the groove 22 is forward and backward, and the length, width and height of the protrusion 21 are all larger than the corresponding length, width and height of the groove 22. Slightly smaller, so the boss 21 can be completely inserted in the groove 22 of another brick. A convex column 31 is arranged to the left in the middle position of the left plane of the brick body, and the shape of the convex column 31 is a cuboid; a groove 32 is arranged to the left in the middle position of the right plane of the brick body, and the shape of the groove 32 is a cuboid; The direction of 32 is all forward and backward, and the length, wi...

Embodiment 3

[0024] See Figure 3 for details, which is basically the same as Embodiment 2, except that the directions of the upper and lower plane protrusions 21 and the grooves 22 are changed to left and right.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com