Structure of cutting tip and saw blade including the structure

A cutting-edge and saw-blade technology, applied in the field of cutting tip structures, can solve the problems that objects cannot be cut accurately, shorten the service life of the saw blade, and degrade the strength of the steel body, achieve good cooling efficiency, simplify the manufacturing process, and prolong the service life. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

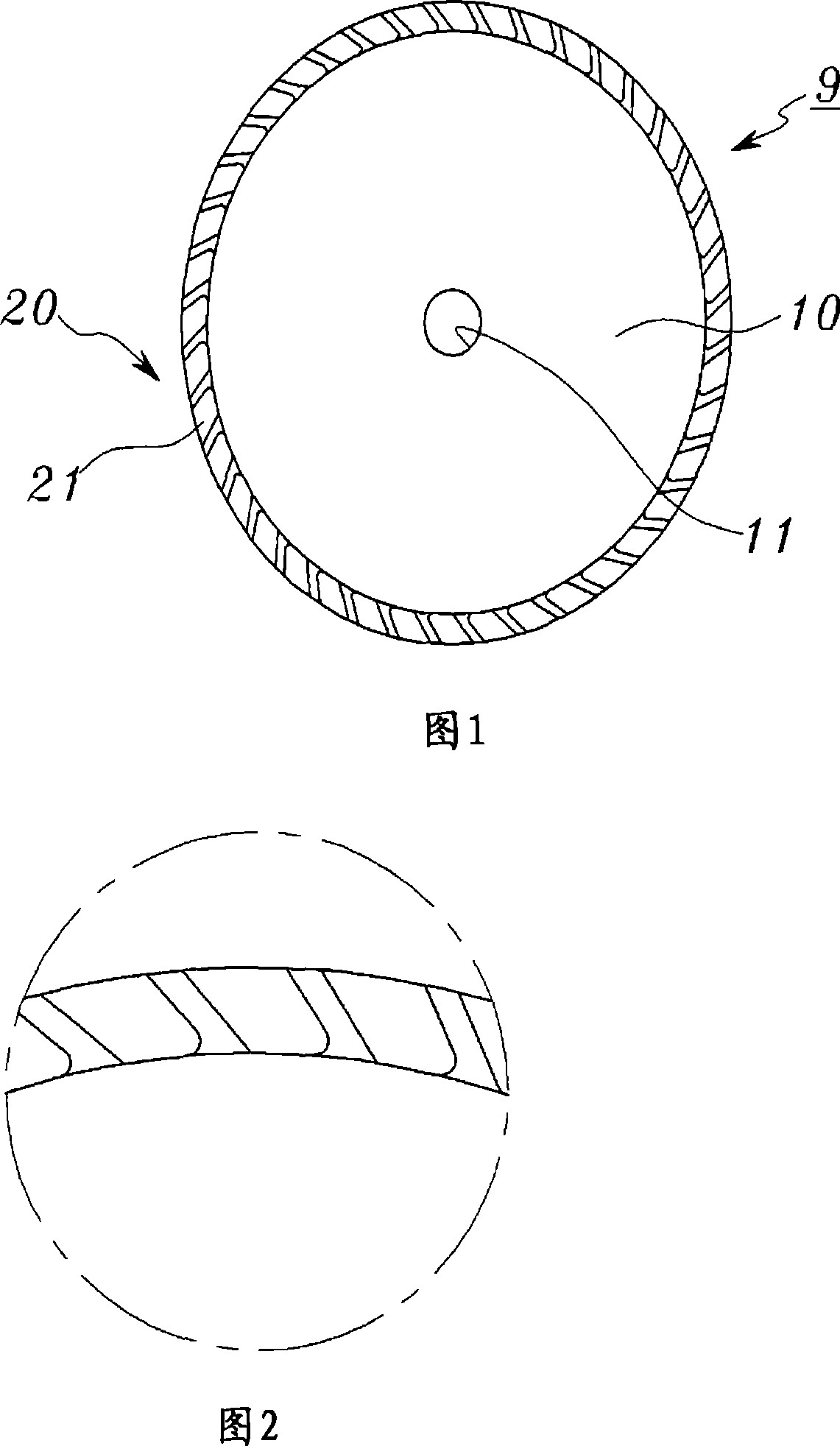

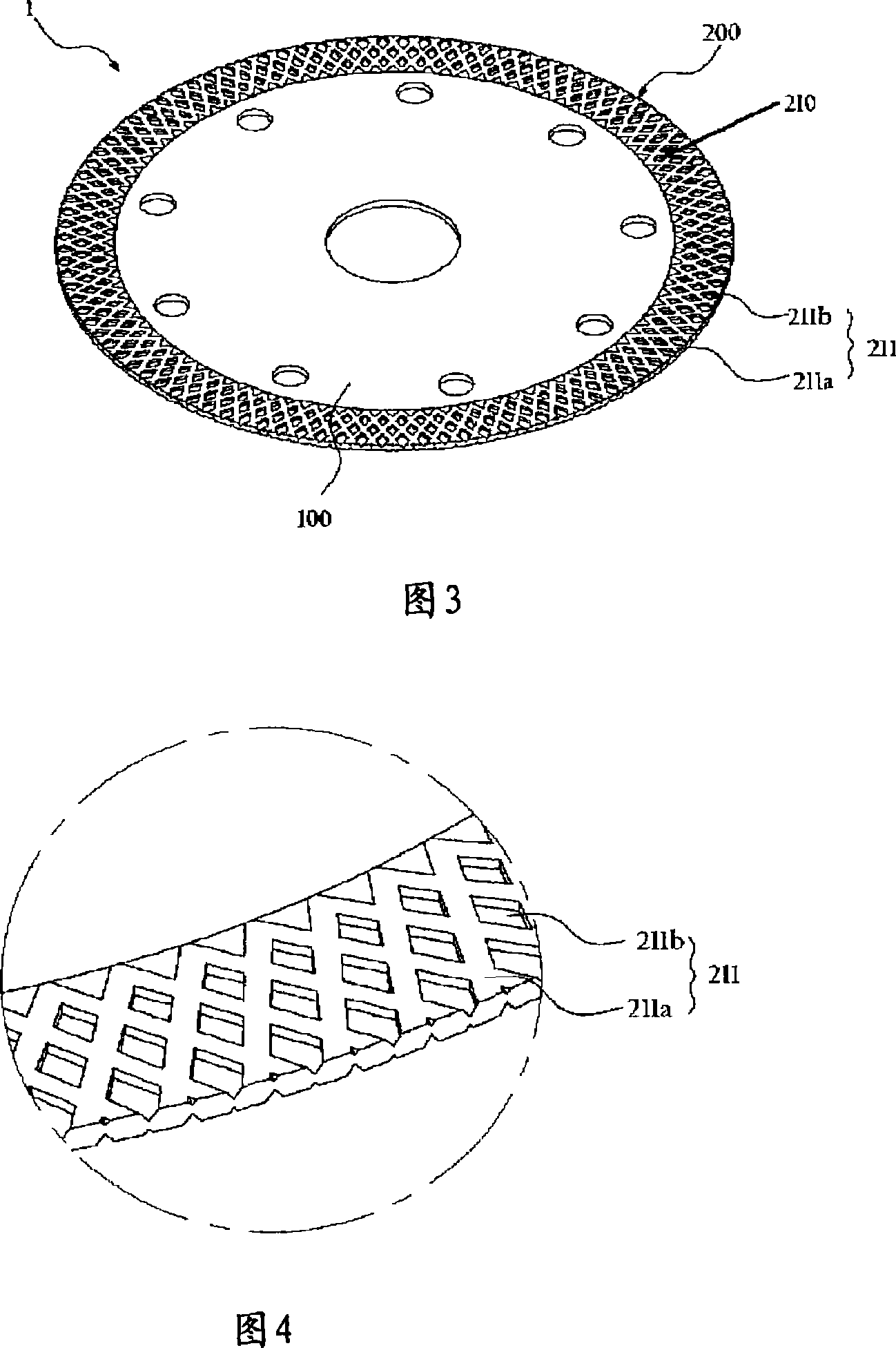

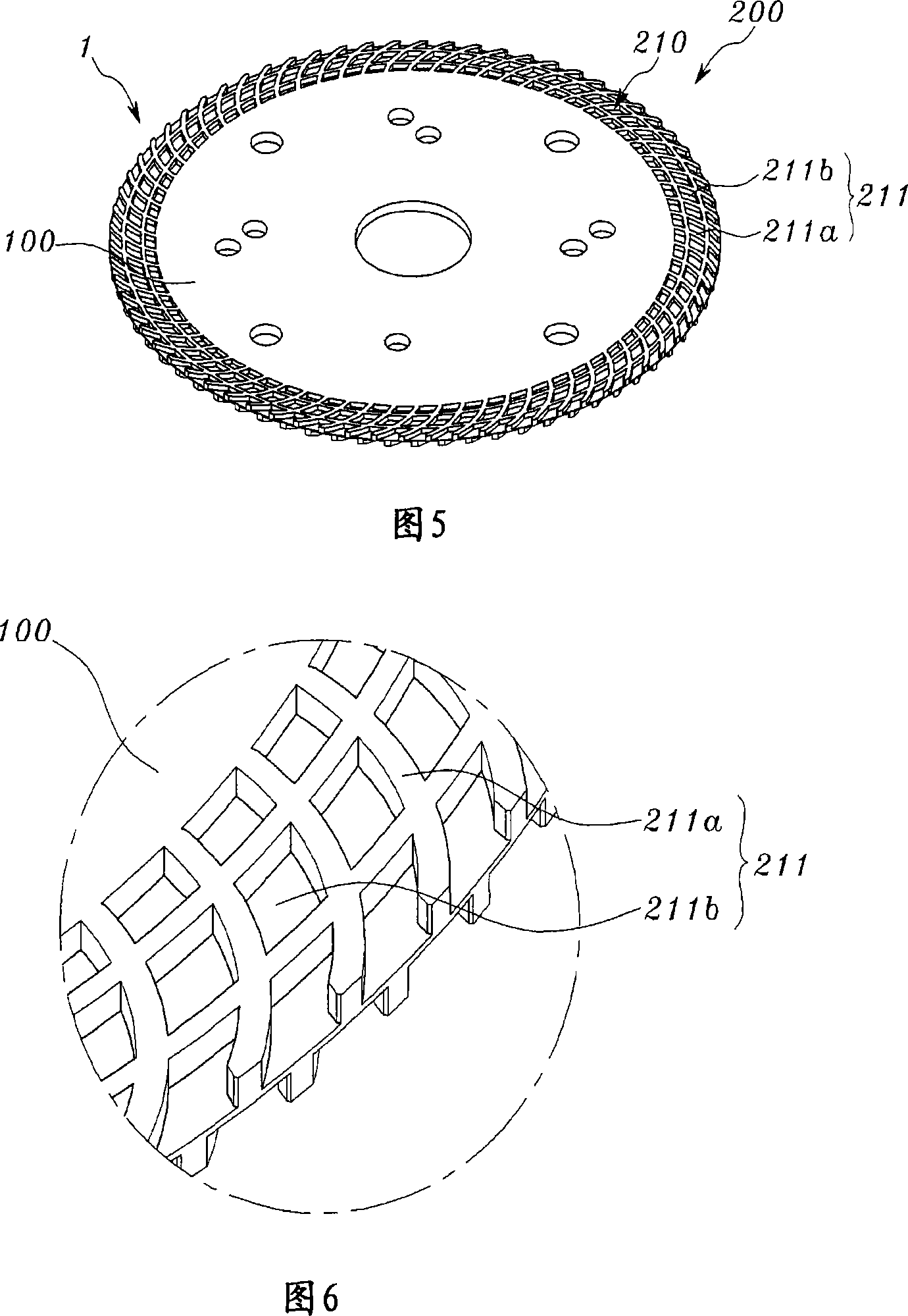

[0057] [54] Next, a cutting tip and a saw blade having the cutting tip according to preferred embodiments of the present invention will be described with reference to the accompanying drawings.

[0058] [55] FIG. 3 is a perspective view of a circular saw blade with a cutting tip according to one embodiment of the present invention, FIG. 4 is an enlarged view of the cutting tip shown in FIG. 3 , and FIG. 5 is a circular saw blade with a cutting tip according to another embodiment of the present invention. A perspective view of a circular saw blade, Figure 6 is an enlarged view of the cutting tip shown in Figure 5, and Figure 7 is a cavity formed in the cutting tip when the circular saw blade shown in Figure 3 and Figure 5 is used for the cutting process schematic diagram.

[0059] [56] FIGS. 3 to 6 show a circular saw blade 1 for cutting an object such as ferrite material, stone material, metal material or ceramic tile. Referring to FIGS. 3 to 6 , the circular saw blade 1 incl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com