Floating taper cock valve

A plug valve and cone technology, applied in the field of floating cone plug valve, can solve the problems of complex valve structure, the plug valve has not been widely used, and the operation is inconvenient, and achieves the effect of reliable sealing, good sealing performance and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

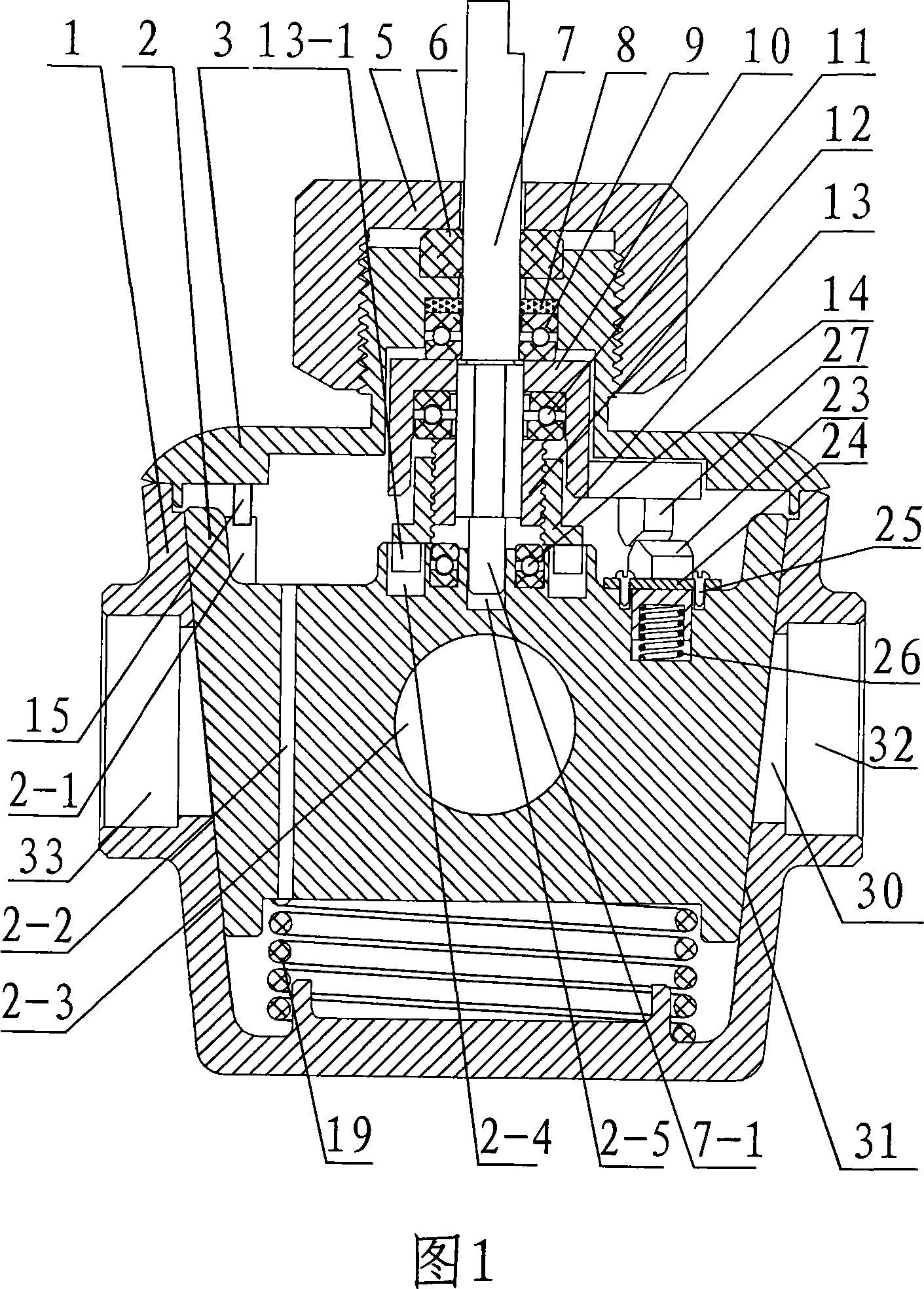

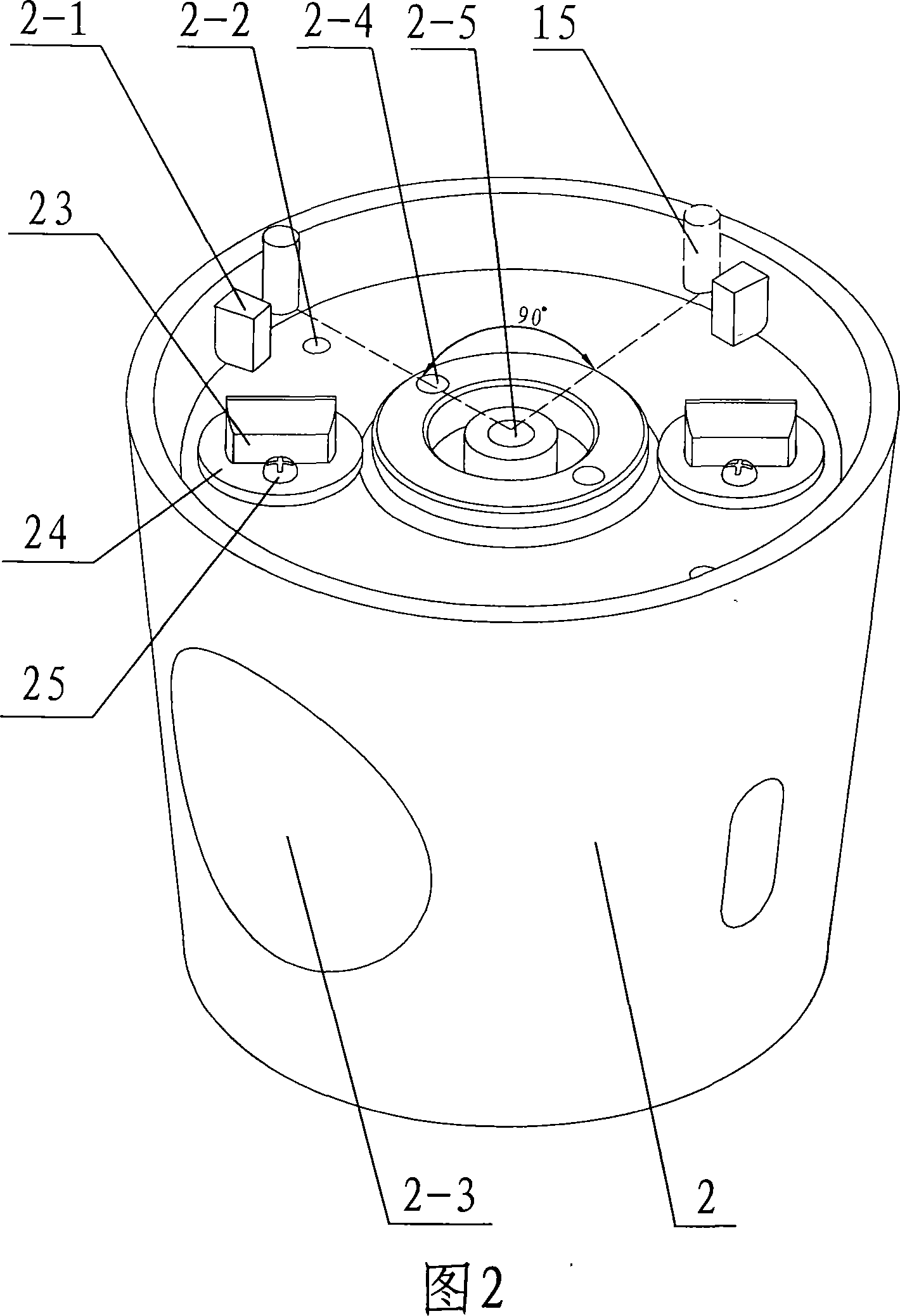

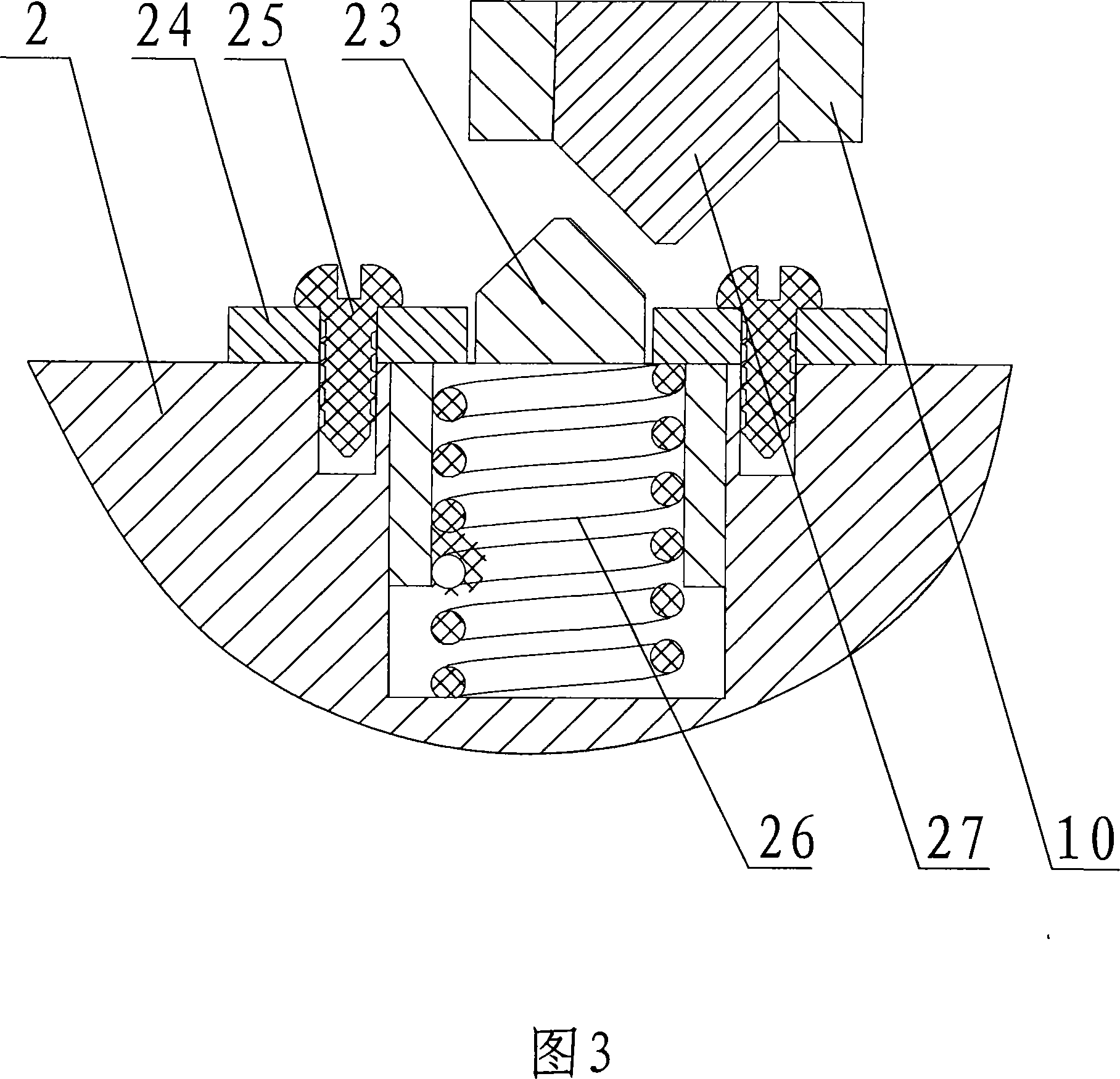

[0034] As shown in Figure 1, it is a structural diagram of a floating conical plug valve. The valve is in a closed state. The floating conical plug valve includes a valve body 1. The valve body 1 has an inlet 32 and an outlet 33. The valve body 1 is provided with a supply valve. A through passage 30 through which the medium flows, and the valve also includes a tapered valve cavity 31 intersecting the passage 30, a rotatably set in the valve cavity 31 for blocking the valve in the closed state of the valve. The conical spool 2 of the passage 30, the spool 2 is a floating conical plug spool that can move up and down in the valve chamber 31, the valve also includes a rotary transmission sleeve 10 and a valve stem for rotating the spool 2 7. The rotating transmission sleeve 10 is set outside the valve stem 7. A floating spring 19 is provided between the lower part of the valve core 2 and the bottom of the valve body 1. The lower end of the valve cover 3 is provided with a limit p...

Embodiment 2

[0047] As shown in Figure 8, it is a structural schematic diagram of a floating conical plug valve provided with a spring pressure plate steel ball in Embodiment 2. The valve is in a closed state, and a steel ball is provided between the bottom center of the valve core 2 and the spring 19 through a spring pressure plate 17. 18, its purpose is to reduce the friction between the spring 19 and the spool 2 when the spool rotates, and the rest are the same as in embodiment 1.

Embodiment 3

[0049] As shown in Figure 9, it is a schematic structural diagram of a four-way floating conical plug valve in Embodiment 3. The difference from Embodiment 1 is that the valve core 2 is provided with two flow channels 2-7 and 2-8, and the valve body 1 is provided with etc. Angle D, E, F, G four ports, the rest are the same as embodiment 1, port D and port E communicate with flow channel 2-7, port F and port G communicate with flow channel 2-8, when spool 2 After rotating 90 degrees counterclockwise, port D and port F communicate with flow channel 2-7, and port E and port G communicate with flow channel 2-8 to achieve the purpose of fluid reversing.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com