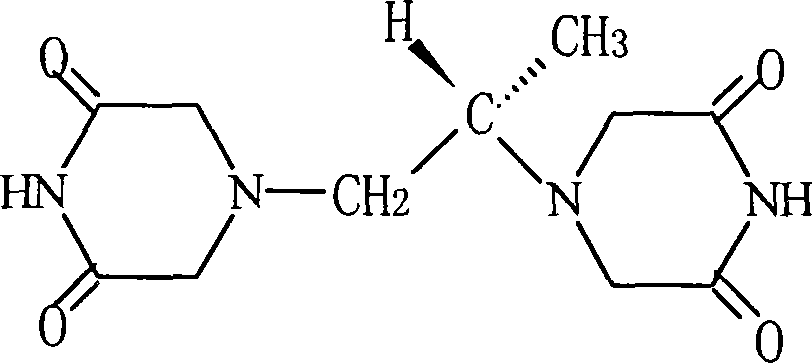

Method for refining dexrazoxane

A technology for dextropropane imine and triethylamine, which is applied in the field of refining dextropropane imine, can solve the problems of high residual solvent, low purity, dark color and the like in the product, and achieves the effects of high purity, good color and luster, and high yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

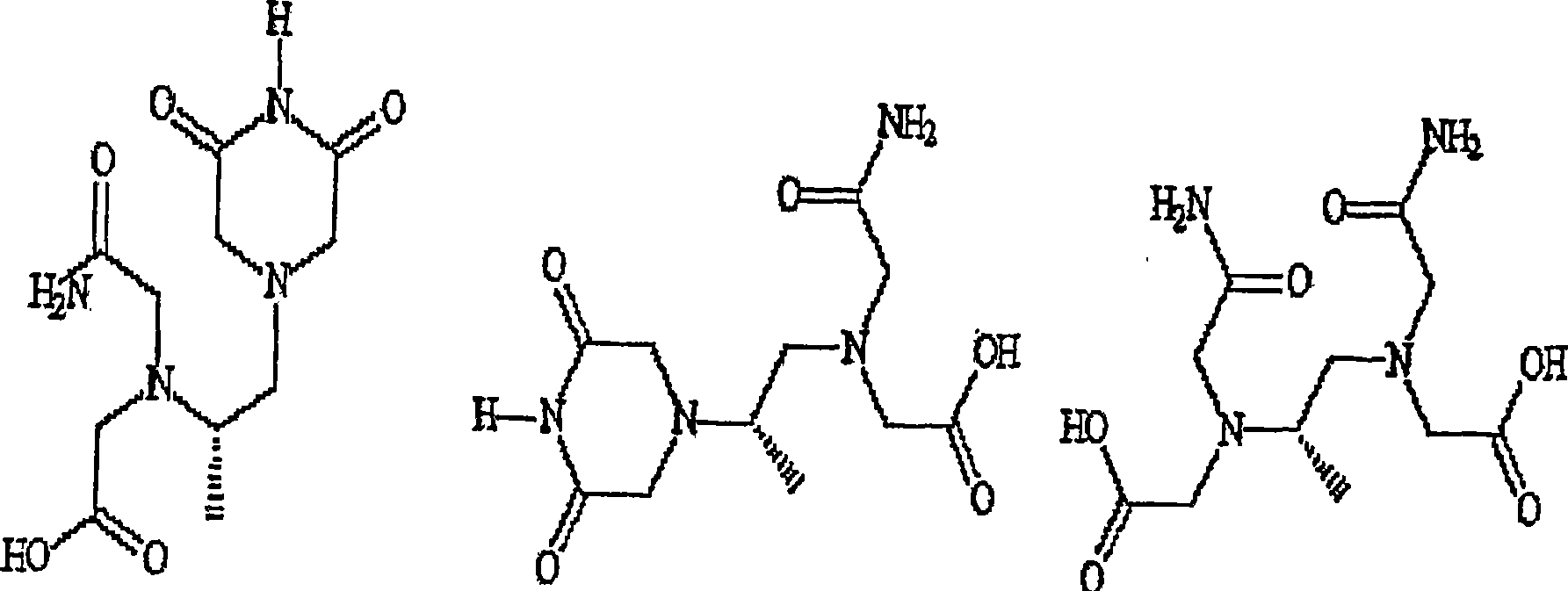

Method used

Image

Examples

Embodiment 1

[0021] Take 50 g of the crude product of dextropropylimine (content 96.50%, pink), add 200 ml of methanol, add hydrogen chloride methanol solution under stirring, the solid gradually dissolves and clarifies and precipitates off-white crystals, adjust the pH value to 1, filter, discard the filtrate, and Mix the filter cake with 200ml of methanol, adjust the pH value to 8 with triethylamine under stirring, filter, rinse the filter cake with methanol, filter dry, and dry under vacuum at 40°C to obtain 44.5 g of white crystals of dextropropylimine, with a yield of 89.0%; The content detected by HPLC is: 99.92%.

[0022] Determine according to high performance liquid chromatography (two appendix VD of Chinese Pharmacopoeia edition in 2005)

[0023] HPLC chromatographic conditions: octadecylsilane bonded silica gel is used as filler; methanol-0.01mol / L potassium dihydrogen phosphate solution (15:85) is used as mobile phase, and the detection wavelength is 208nm. The number of theor...

Embodiment 2

[0025] Take 20 g of the crude product of dextropropylimine (content 96.50%, pink), add 200 ml of ethanol, add hydrogen chloride ethanol solution under stirring, adjust the pH value to 1, filter, discard the filtrate, mix the filter cake with 200 ml of ethanol, mix with three Adjust the pH value to 8 with ethylamine, filter, rinse the filter cake with ethanol, filter dry, and vacuum-dry at 40°C to obtain 15.5 g of white crystals of dextropropylimine, with a yield of 77.5%; the content detected by HPLC is: 99.63%. HPLC condition is the same as embodiment 1.

Embodiment 3

[0027] Take 10 g of the crude product of dextropropylimine (content 96.50%, pink), add 150 ml of isopropanol, add hydrogen chloride isopropanol solution under stirring, adjust the pH value to 2, filter, discard the filtrate, and mix the filter cake with 200 ml of isopropanol Mix, adjust the pH value to 9 with triethylamine under stirring, filter, rinse the filter cake with isopropanol, filter dry, and vacuum-dry at 40°C to obtain 8.4 g of white crystals of dextropropylimine, with a yield of 84.0%; HPLC detection content For: 99.68%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com