Synthesis of silicon based ceramic forerunner by chloro-silicane hybrid aminolysis modification and preparation method thereof

A ceramic precursor and a technology for the precursor are applied in the field of dichlorosilane mixed aminolysis modification to synthesize a silicon-based ceramic precursor and the preparation thereof, can solve the problems of unsuitability for industrialized production and high toxicity of the reaction system, and achieve low cost and high reaction efficiency. The effect of easy control of conditions and low toxicity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

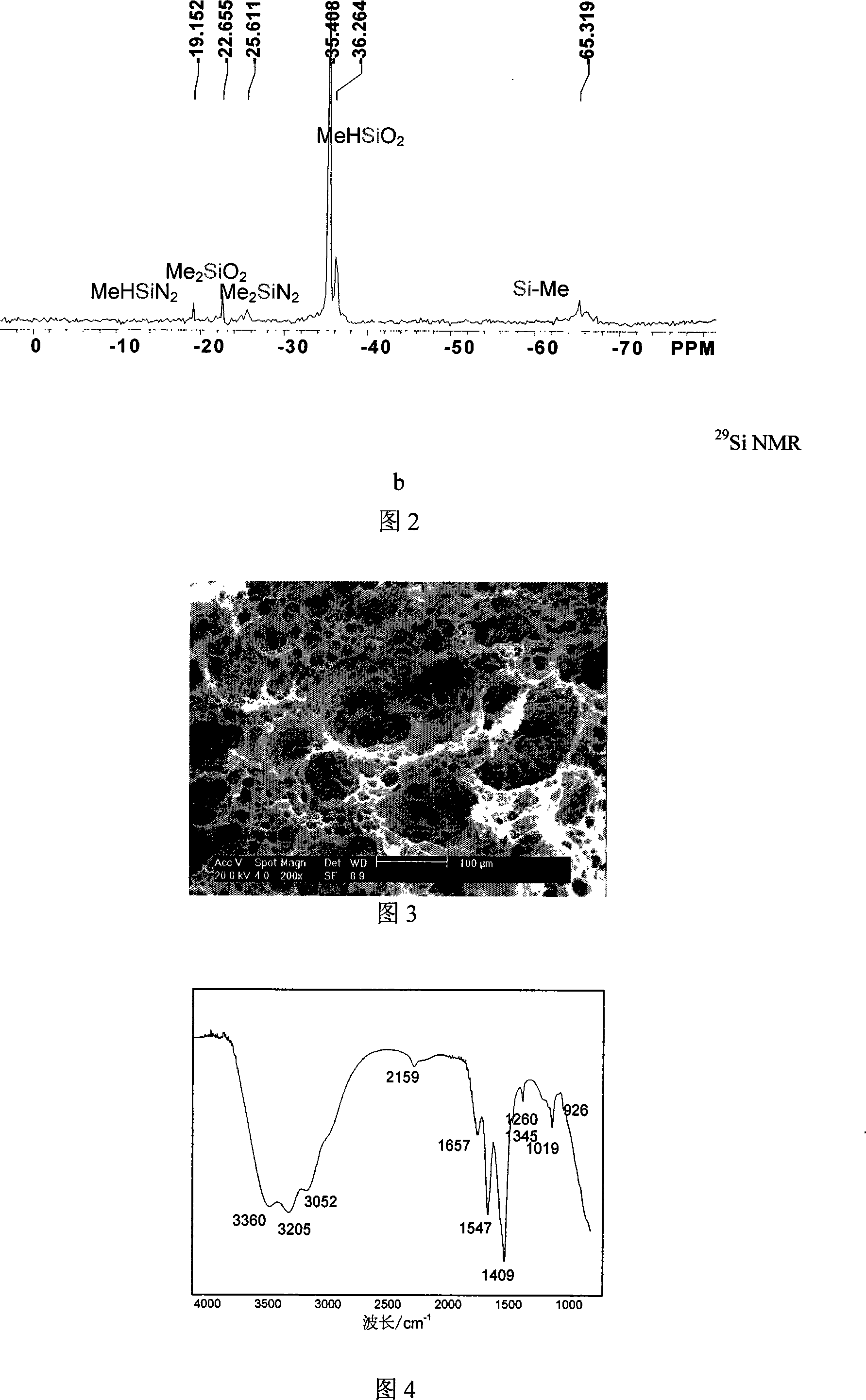

Embodiment 1

[0021] Embodiment 1: 3.15g methylhydrogendichlorosilane and 2.38g dimethyldichlorosilane are magnetically stirred and mixed (the molar ratio is 3:2), the system is vacuumized (vacuum degree 100Pa) and ammonia gas (flow rate: 20mL / min), when the dichlorosilane is completely ammonolyzed (about 10 minutes), add 0.2 g of acetic acid amide, 0.1 g of bromine water and 0.1 mL of sodium hydroxide (0.5 mol / L) solution dropwise with a dropper, and react for 15 minutes to form The liquid precursor will form a solid precursor after standing for 15 hours. The solid precursor was dried at 150°C in argon for 6h, then heated at a rate of 5°C / min under an argon atmosphere, and pyrolyzed at 1200°C to obtain a porous ceramic with an average pore size of 100 μm.

Embodiment 2

[0022] Embodiment 2: 3.15g methylhydrogendichlorosilane and 3.57g dimethyldichlorosilane are magnetically stirred and mixed (the molar ratio is 1:1), and the system is evacuated (vacuum degree 100Pa) and ammonia gas (flow rate: 30mL / min), until dichlorosilane is completely ammonolyzed (about 10 minutes), add 0.3g acetic acid amide, 0.2g bromine water and 0.2mL sodium hydroxide (concentration 0.5mol / L) solution dropwise with a dropper, pH = 10, and react A liquid precursor was formed after 20 minutes, and a solid precursor was formed after 15 hours of standing. The solid precursor was dried in argon at 150°C for 6h, then heated at a rate of 5°C / min in an argon atmosphere, and pyrolyzed at 1200°C to obtain a porous ceramic with an average pore size of 30 μm.

Embodiment 3

[0023] Embodiment 3: 7.35g methylhydrogendichlorosilane and 3.57g dimethyldichlorosilane are magnetically stirred and mixed (the molar ratio is 7: 3), the system is vacuumized (vacuum degree 100Pa) and ammonia gas (flow rate: 30mL / min), until the dichlorosilane is completely ammonolyzed (about 20 minutes), add dropwise 0.4g acetic acid amide, 0.2g bromine water and 0.5mL sodium hydroxide (concentration 0.5mol / L) solution with a dropper, pH = 12, and react A liquid precursor was formed after 30 minutes, and a solid precursor was formed after 15 hours of standing. The solid precursor was dried in argon at 150°C for 6h, then heated at a rate of 5°C / min in an argon atmosphere, and pyrolyzed at 1200°C to obtain a porous ceramic with an average pore diameter of 5 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com