Cab structure for engineering machinery vehicle and vehicle with same structure

A construction machinery and cab technology, applied in the field of cab structure, can solve problems such as inconvenient assembly and rising costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Embodiments of the present invention will be described in detail below with reference to the accompanying drawings.

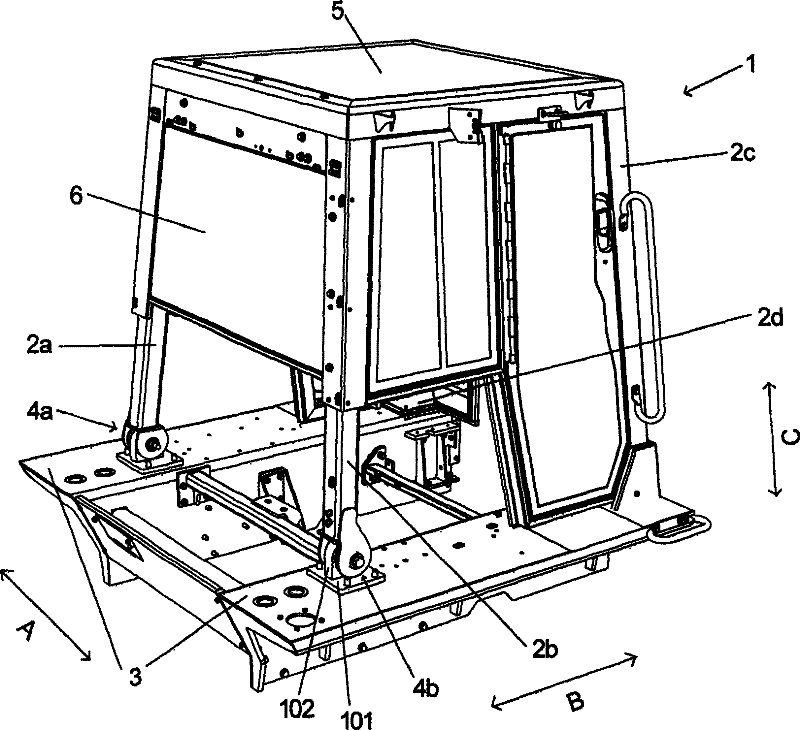

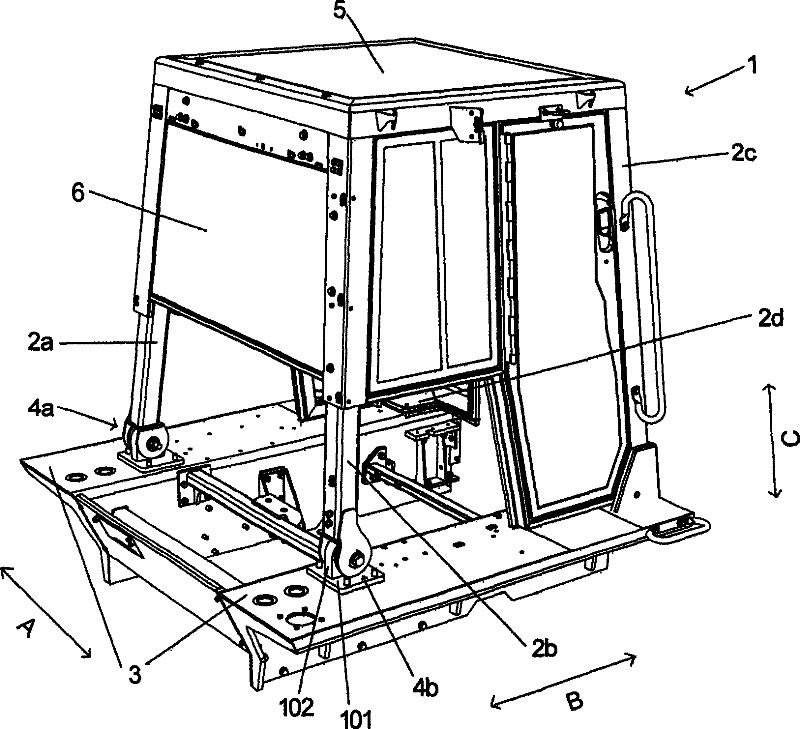

[0018] The cab according to the invention can be used in various engineering machinery vehicles, such as (crawler) excavators, bulldozers, road rollers, cranes and the like. figure 1 A perspective view of the cab 1 according to an embodiment of the present invention is shown, in which arrow A indicates the vehicle width direction (lateral direction), arrow B indicates the vehicle length direction (longitudinal direction), and arrow C indicates the vertical direction. The cab comprises four vertically or slightly obliquely extending structural members or struts 2a, 2b, 2c and 2d (wherein although only the lower end of strut 2d is shown, strut 2d is substantially similar in construction to the other struts). These pillars are made of high-strength rigid material such as steel, and are connected and fixed together by the top 5 and the four side wall parts 6...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com