Syringe premounting sealing method

A technology for syringes and sealing sleeves, which is applied in the field of syringe prepackaging and sealing, and can solve problems such as technology, cost, use restrictions, and failure to popularize

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

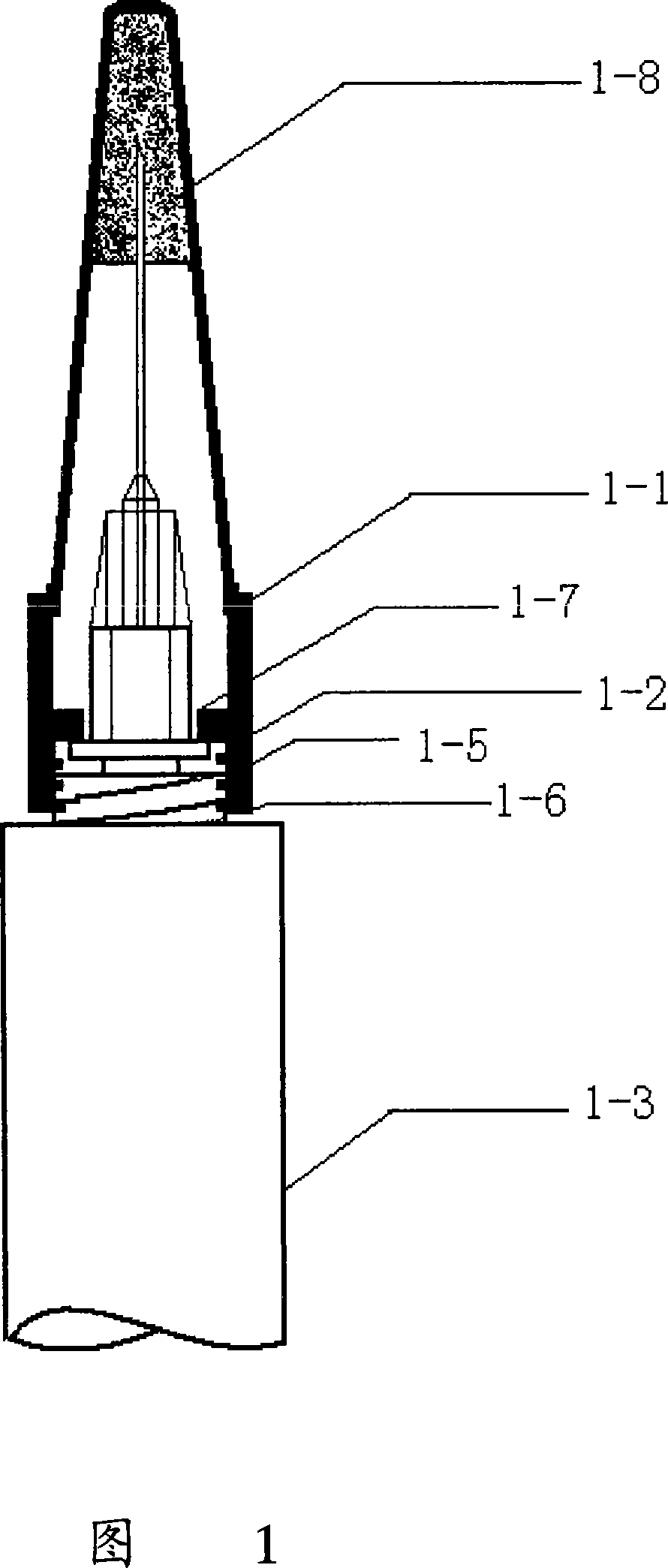

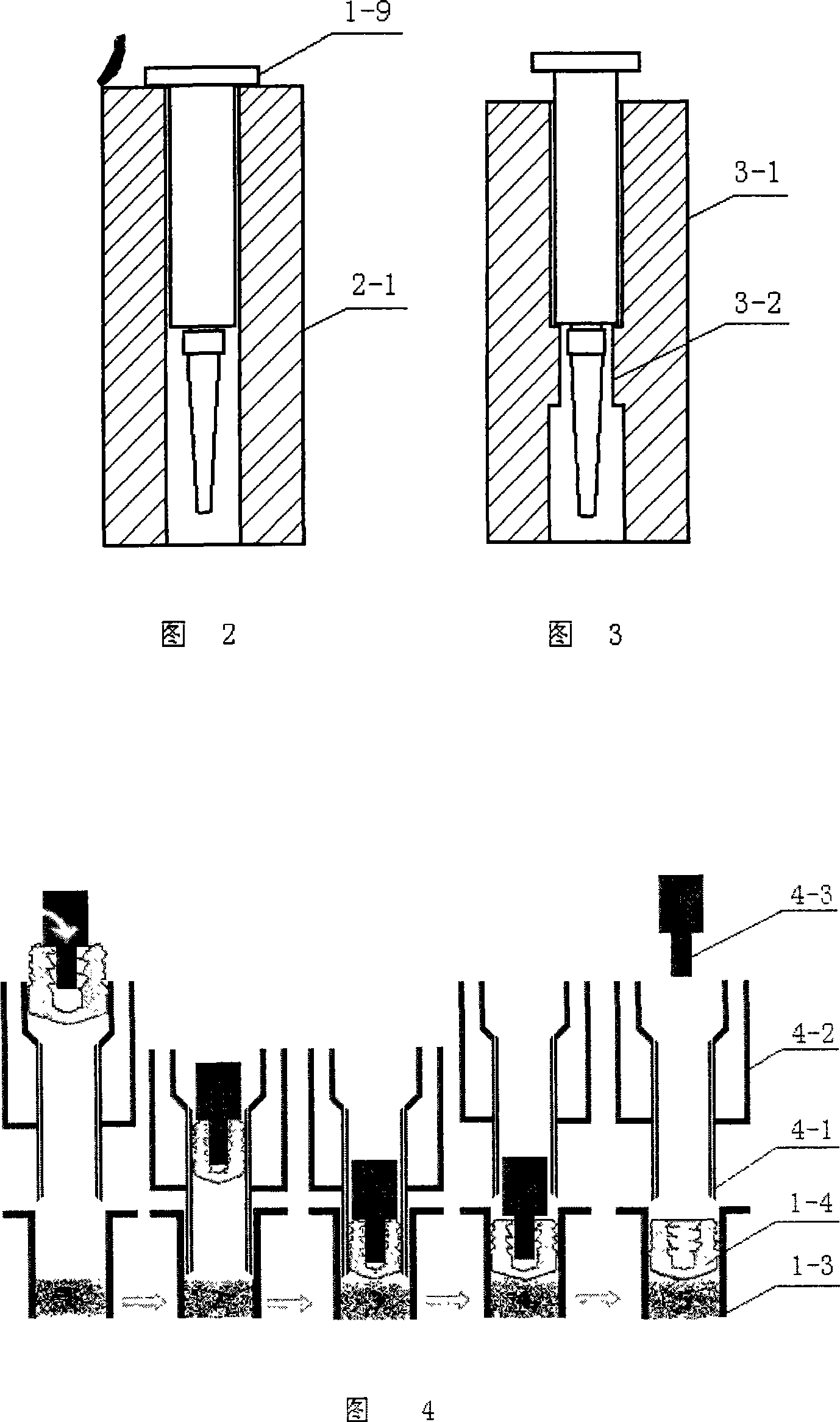

[0014] The method of the invention can be used to prepack and seal syringes on general filling lines. In the specific implementation, first use the needle sealing sleeve to seal the needle end, and place the needle tube body sleeve that has completed the needle end sealing in the body holder, so that it can be pre-filled with medicine on the assembly line like a vial, after the filling is completed It is sealed by the thin tube plugging method of the exhaust needle (the advantage of the plugging method of the thin tube of the exhaust needle is that it does not require the elasticity of the plug rubber, and the plug rubber does not produce wrinkles, etc.), so far the pre-installation sealing stage is completed. In summary, the syringe prepacking and sealing method of the present invention is economical, practical and reliable, and has the characteristics of being easy to implement for improving product quality and upgrading.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com