Distributing transformator electronic type loaded automatic wide region voltage regulating device

A technology for distribution transformers and voltage regulating devices, which is applied to the parts of transformers/inductors, transformers, variable transformers, etc., and can solve the problem of failure to switch or control elements, separation of devices, imperfect protection functions, and short battery discharge time and other problems, to achieve the effect of improving the low voltage qualification rate and the difficulty of voltage regulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

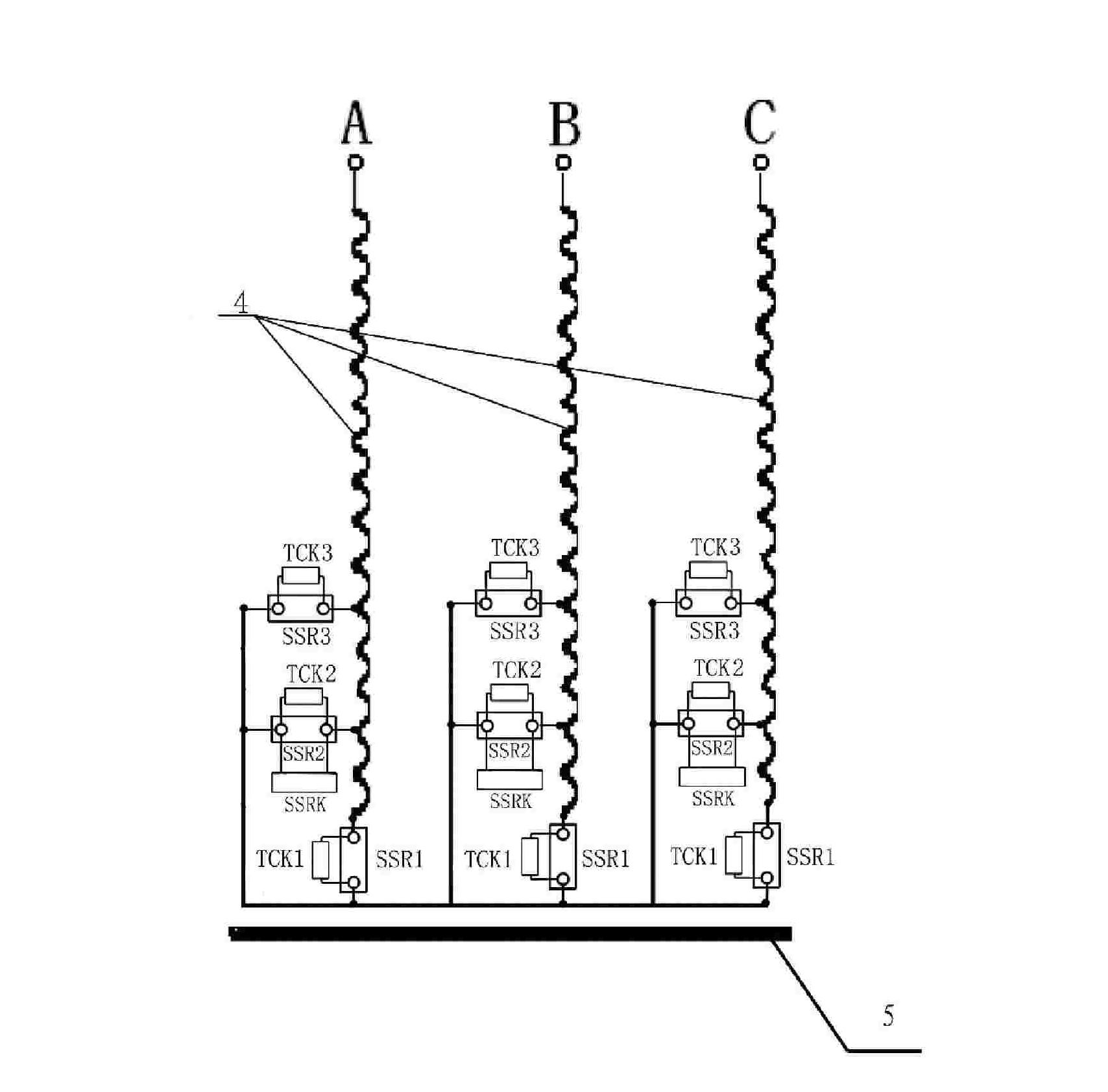

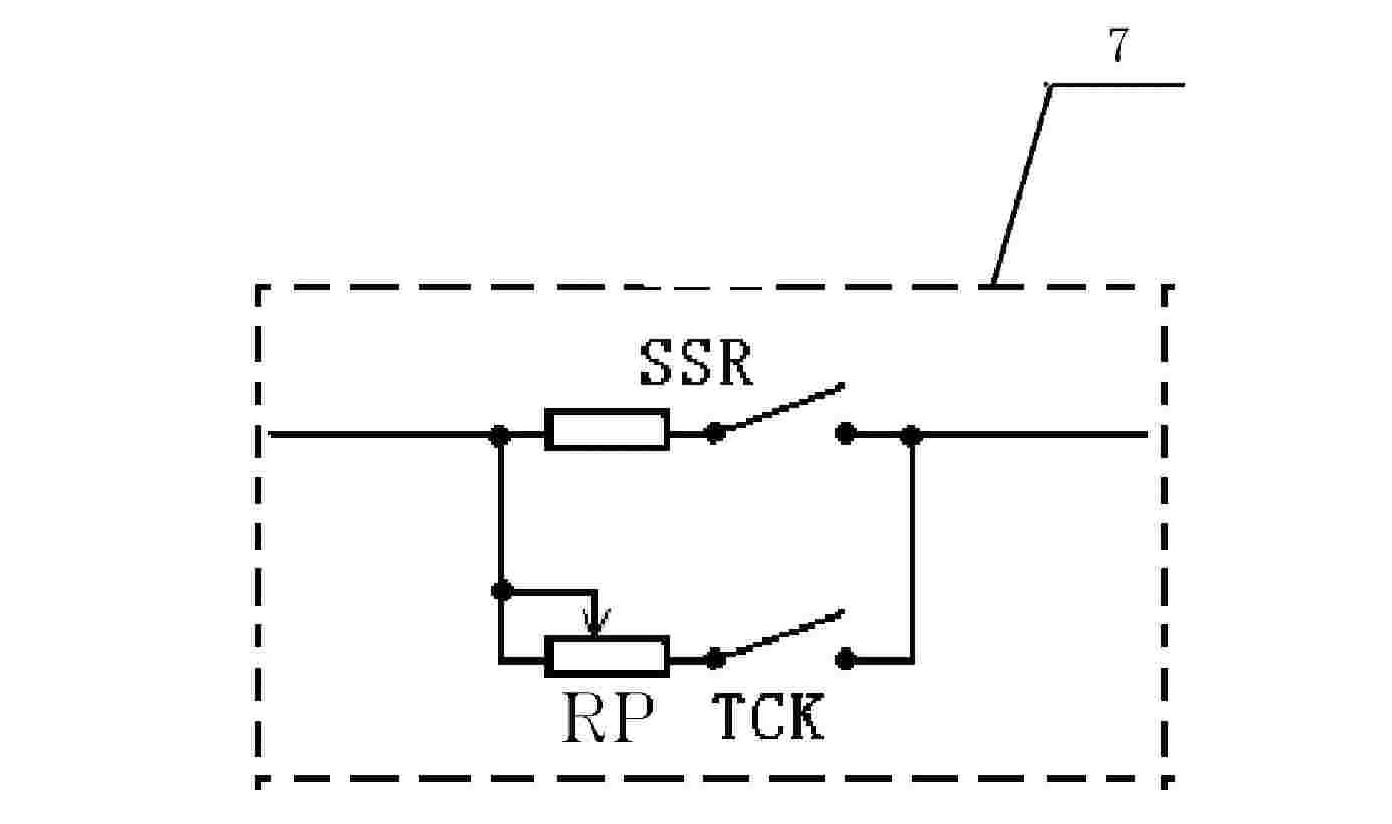

[0069] Refer to figure 1 , each dual-relay main control switch (SSR and TCK connected in parallel) is connected to the tap (7) on the corresponding level of the high-voltage side winding of the transformer, and the other end is connected in parallel as a star point. The voltage regulation level of the transformer is three levels or other odd-numbered levels are selected, and three second-level single-phase AC solid-state relays (SSR2 ) are respectively connected in parallel with a normally closed solid-state relay (SSRK) as a gatekeeper switch to form a gatekeeper control unit. The execution of the gatekeeper control unit is controlled by the gatekeeper control circuit. The single-phase AC solid-state relays connected to the command generator and the taps of other voltage-regulating stages are conventional normally open. The wiring scheme for voltage regulation above three gears is designed with reference to the first embodiment.

Embodiment 2

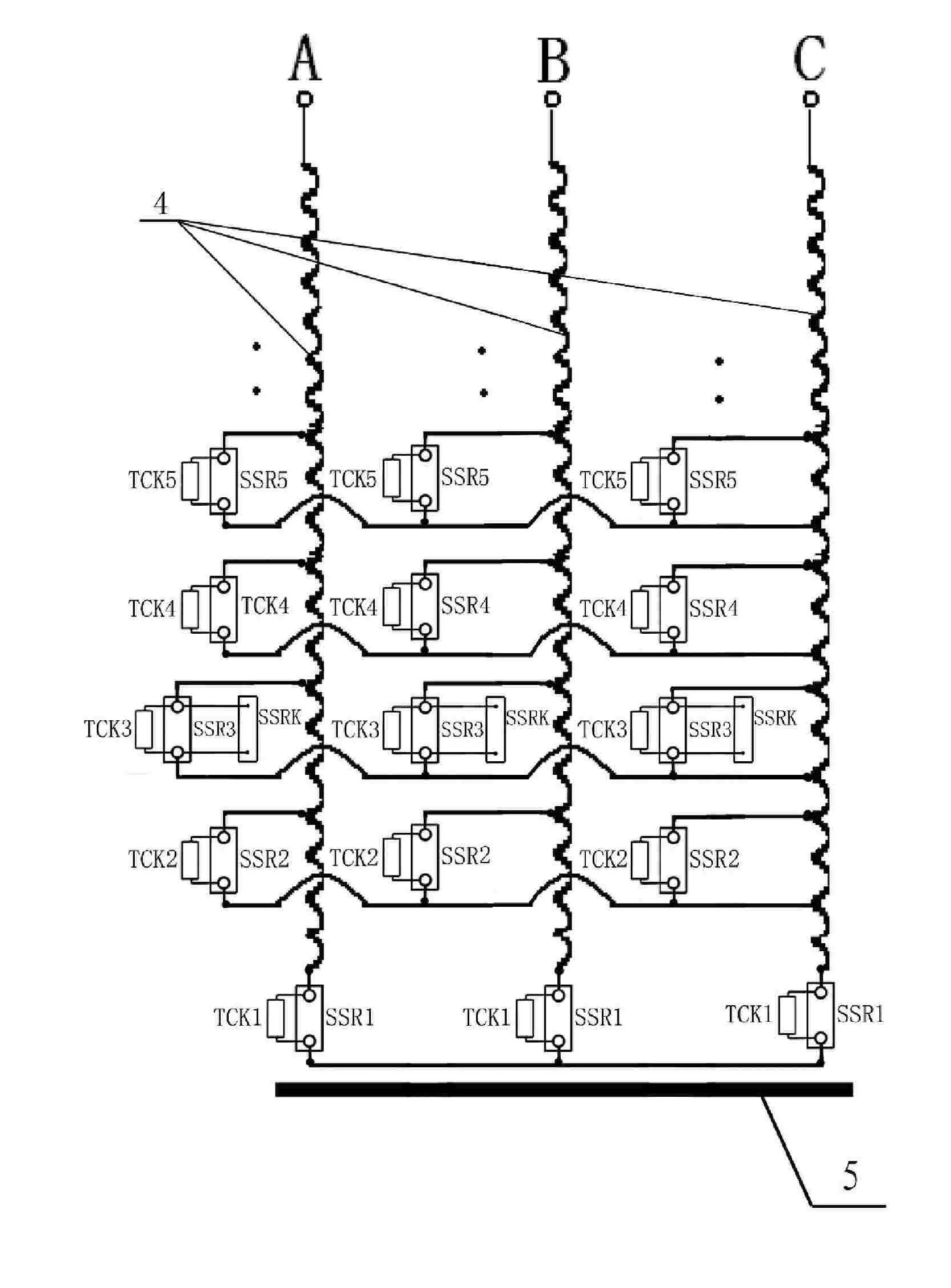

[0070] Refer to figure 2 , the other ends of the five double-relay main control switches (7) on the taps of the same voltage regulation level taps of the three-phase wires (4) of the high-voltage side winding of the transformer are connected in parallel. The voltage regulation level of the transformer is five levels or other odd-numbered levels are selected, and three three-level single-phase AC solid-state relays (SSR3) are connected in parallel on the tap taps of the middle voltage regulation level (that is, the third level) of the high-voltage winding of the transformer. A normally closed solid-state relay (SSRK) acts as a gatekeeper switch to form a gatekeeper control unit. The execution of the gatekeeper control unit is controlled by the gatekeeper control loop. Its upper stage and the three-phase quasi-command generator The single-phase AC solid-state relays connected with taps of other voltage-regulating grades are conventional normally open types. The wiring scheme f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com