Block-resistant material air duct sealing plate used for ring cold machine

A sealing plate and ring cooler technology, which is applied in the device field of blast ring coolers, can solve problems such as vent blockage, and achieve the effect of ensuring normal operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

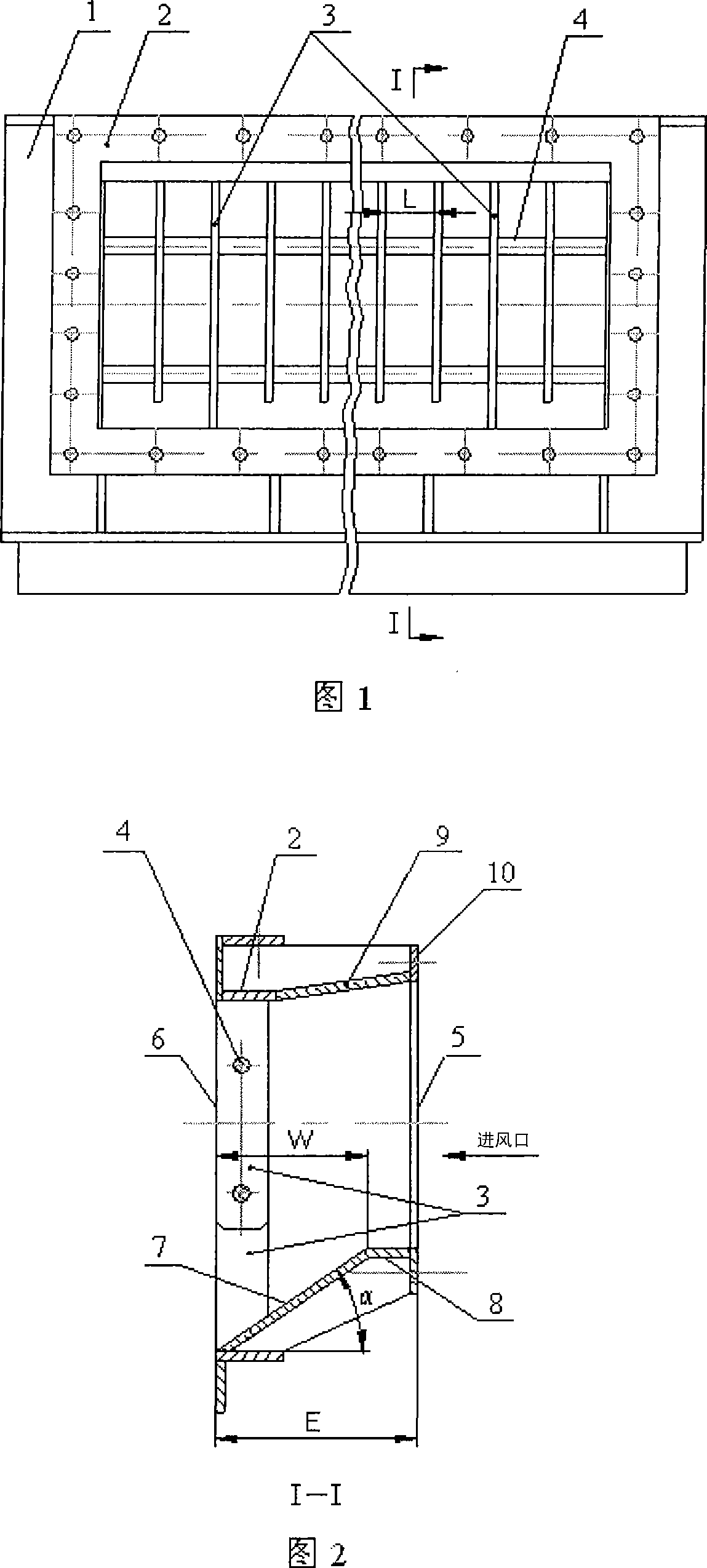

[0016] See Fig. 1 and Fig. 2, the anti-blocking material air duct sealing plate 1 used on the ring cooler is provided with a vent, and an air duct pipe 2 is arranged on the vent opening, and the air duct pipe 2 protrudes obliquely upward from the vent opening, and its The bottom plate has a sloping plate 7 inclined upwards to transition to a horizontal plate 8. The inclination angle α of the sloping plate 7 is greater than or equal to the angle of repose of the material. The horizontal projection W of the sloping plate 7 is always smaller than the length E of the air duct. The top plate above 9 is also inclined upwards, the outermost edge of the air duct pipe 2 is made into a flange interface 10, which is connected with the air duct, and a material-retaining ventilation grid is added on the trolley side of the air duct pipe 2, and the material-retaining ventilation grid is composed of a vertical grid plate 3 Formed with the fixed distance cross bar 4, the height of the ventilat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com