Filament control device for hot-cathode electric ballast

A technology for electronic ballasts and control devices, applied in lighting devices, electric light sources, electrical components, etc., can solve problems such as large filament current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] To start fluorescent tube lighting, the following requirements must be met:

[0034] 1) In the preheating stage of the lamp tube, on the one hand, it is necessary to provide sufficient preheating current for the filament, and on the other hand, the voltage at both ends of the lamp tube should be low enough to ensure that the lamp tube is basically non-conductive, and the cathode of the fluorescent lamp will not be cold-excited to damage the filament ;

[0035] 2) During the working stage of the lamp tube, the voltage at both ends of the lamp tube should be high enough to prompt the lamp tube to start quickly. At the same time, after the fluorescent lamp is started, the filament of the lamp tube should not be conducted, so as to prolong the life of the filament.

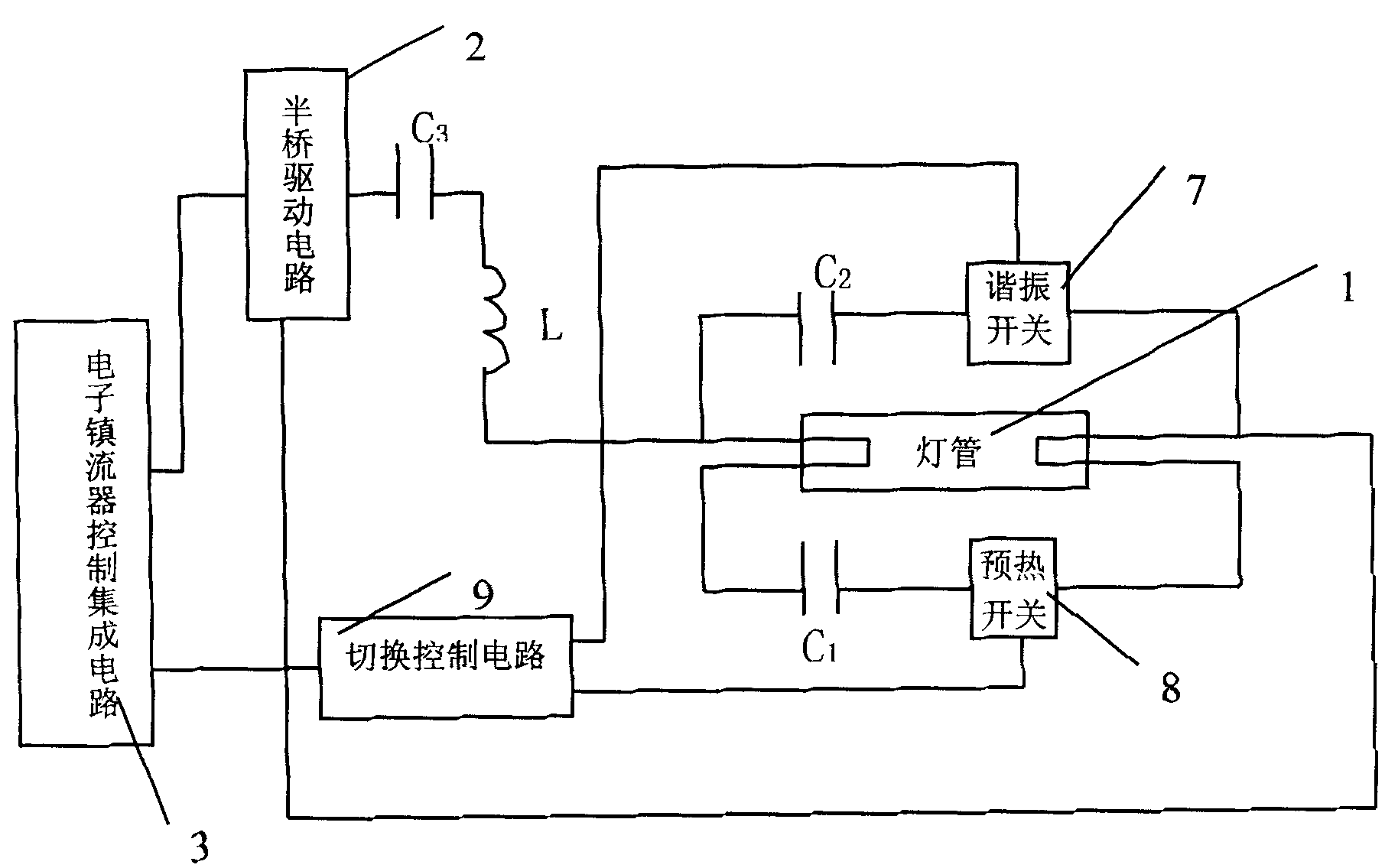

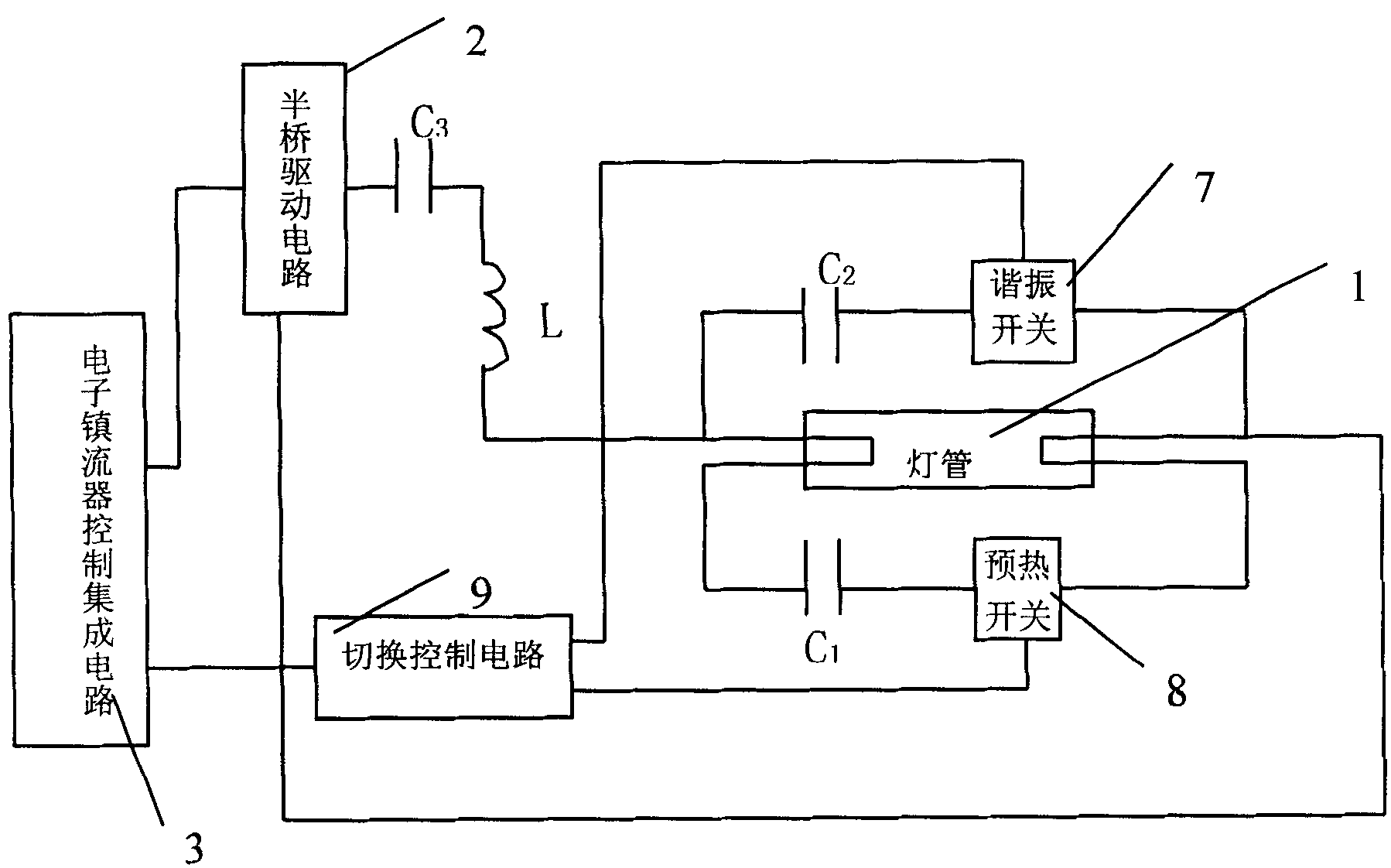

[0036] control figure 1 The following is further described:

[0037] A filament control device for a hot cathode electronic ballast, comprising a lamp tube 1, a half-bridge drive circuit 2 for starting the la...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com