Multi-spire stirring machine

A mixer, multi-spiral technology, applied in the direction of mixers, mixers, dissolving, etc. with rotating stirring devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

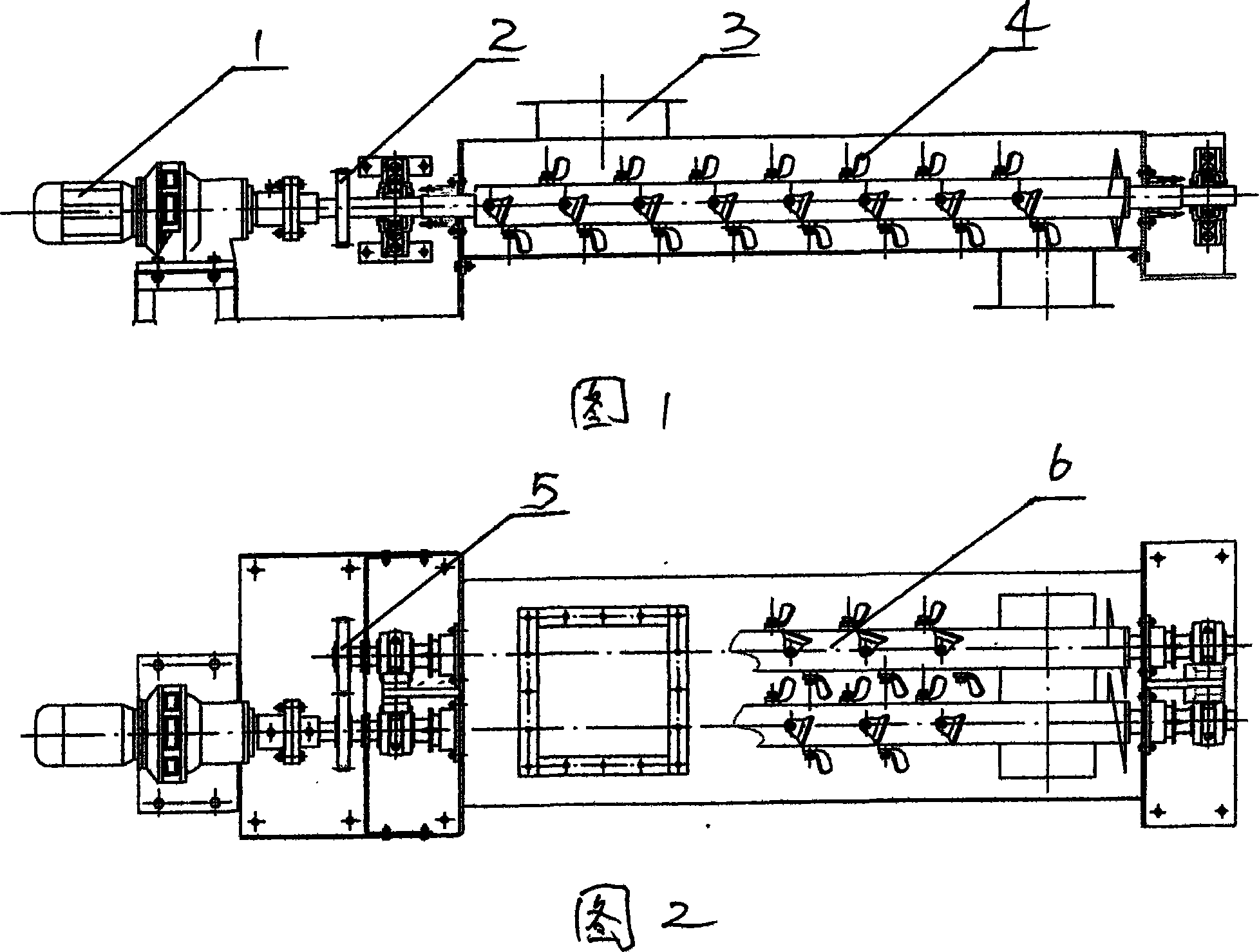

[0010] The present invention is further described in conjunction with accompanying drawing:

[0011] In practical applications, the drive motor (1) drives the active shaft to rotate, so that the active gear (2) will drive the passive gear (5), thereby driving the passive shaft to rotate in the opposite direction, so that the active shaft drives the spiral mixing blade (4), and the passive shaft drives The spiral stirring blade (6) rotates inwards, so that the hardened material is crushed quickly by the spiral stirring blade.

[0012] According to practice, the spiral mixer of the present invention is 3 to 10 times higher than manual operation, and the pulverization is more thorough.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com