Control method of transverse sealing instrument employing control engine

A control method and technology of horizontal sealing device, applied in sequence/logic controller in the direction of program control, packaging automatic control, electrical program control, etc., can solve the problems of complex structure, time-consuming, inconvenient production, etc., and reduce production costs. , Overcome the effect of material waste

Inactive Publication Date: 2010-11-24

天津奥特玛科技有限公司

View PDF1 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

In this control method and equipment, the speed change of the horizontal sealing roller is still generated by the sprocket drive pair, and its structure is complex. According to the division of the eccentricity Δ, it is necessary to equip multiple passive eccentric sprockets with different eccentricity. When adjusting the eccentricity, It is necessary to select the appropriate passive eccentric sprocket according to the length of the bag, and then move the driving sprocket to the position corresponding to the corresponding passive sprocket, so as to complete the adjustment of the sprocket drive pair under the specified bag length

It can be seen from this that the adjustment of the eccentricity Δ not only needs to be stopped for adjustment, but also the adjustment process is cumbersome and requires a certain amount of man-hours, which brings inconvenience to production.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

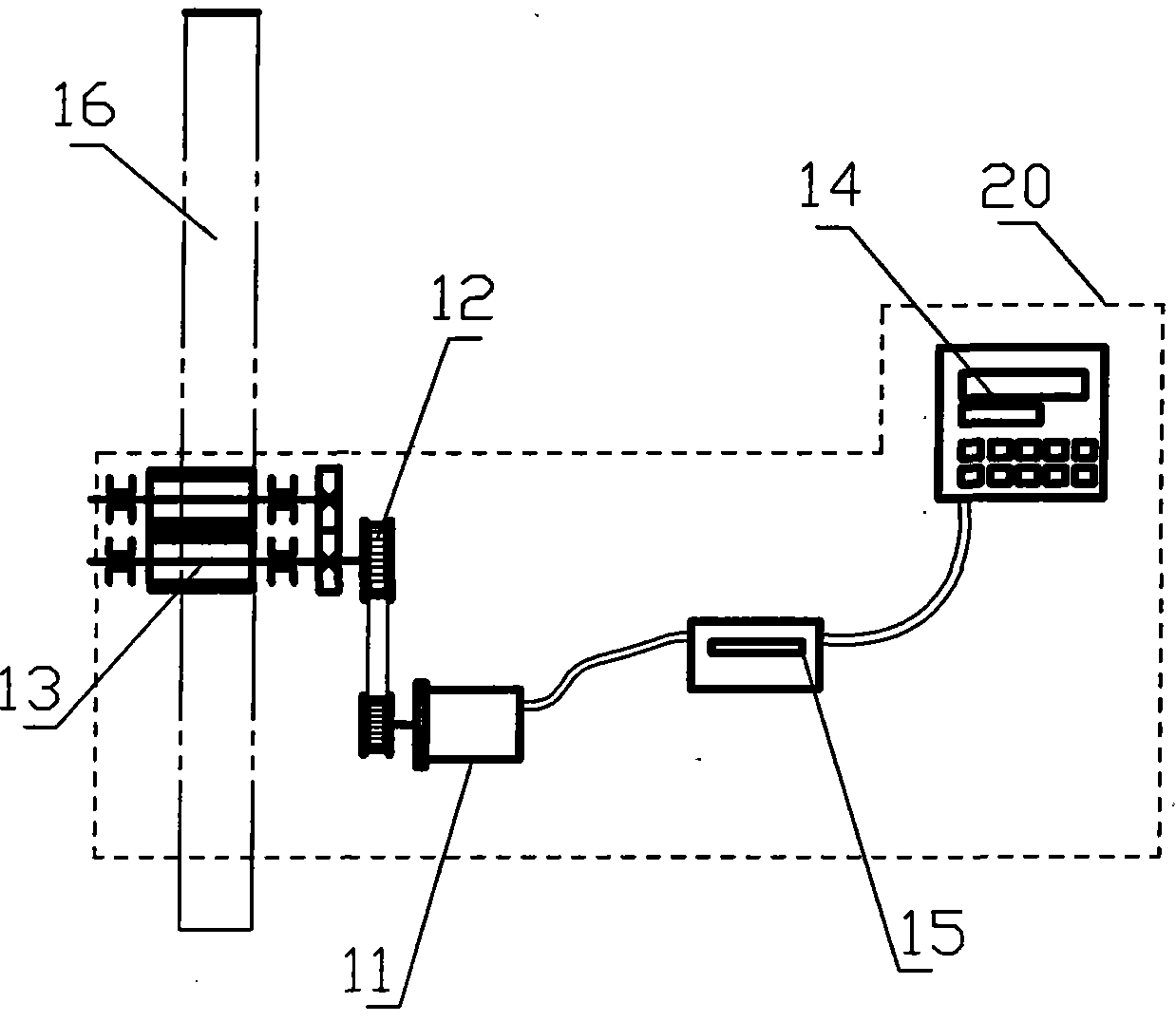

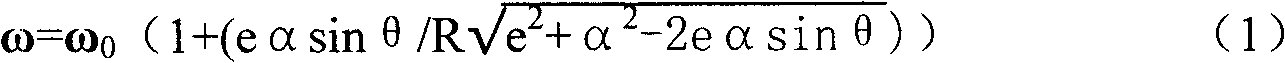

The present invention discloses a control device for a traverse seal with a control motor, which comprises a control motor, an amplifier and a microcomputer controller that are sequentially connected with a traverse seal roller. The control method of the control device includes the following steps: the traverse seal roller is initialized to zero angle position through switching signals on the traverse seal after the electrical source is connected; a bag-sealing length value L is input through a human-computer dialogue interface composed of a keyboard and a display; the CPU of the microcomputer controller figures out the instantaneous angular velocity omega when the traverse seal roller makes rotation with varying speed within a 360-degree cycle in accordance with the following formula; then the numerical value omega is converted into pulse value to be sent to the amplifier; the control motor receives the angular displacement signal from the amplifier to realize the speed-varying rotation of the control motor; driven by the control motor, the traverse seal roller realizes speed-varying rotation. The present invention simplifies the mechanical structure of a packing machine, and is simple to adjust and easy to implement, which can change the size of the packaging bag under the start-up state of the machine, save the packaging materials and improve the work efficiency of the packing machine.

Description

A horizontal sealer control method that controls the motor is adopted technical field The invention relates to a control method of a packaging machine, in particular to a control method of a horizontal sealer in a vertical packaging machine. Background technique At present, most of the continuous vertical packaging machines use rotary type horizontal sealing rollers. Usually the radius of the horizontal sealing rollers is fixed, so it is necessary to use a non-uniform movement mechanism (such as an eccentric sprocket mechanism) to drive it to properly adjust Its sealing line speed can meet the requirements of heat sealing. As shown in Figure 1-1, Figure 1-2 and Figure 1-3, the existing technological requirements for the horizontal sealer in a continuous vertical bag filling machine are: when heat sealing, the heat sealing head and the continuously moving The bag tube must have a synchronous linear speed. Since the radius of the heat-sealing head is fixed, it is often driv...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B65B51/10B65B57/00G05B19/04

Inventor 宋昕

Owner 天津奥特玛科技有限公司

Who we serve

- R&D Engineer

- R&D Manager

- IP Professional

Why Patsnap Eureka

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com