Vertical type full automatic plate-and-frame filter press, and filter technique

A plate-and-frame filter press, a fully automatic technology, applied in filtration and separation, separation methods, chemical instruments and methods, etc., can solve the problem of inability to achieve automatic filter press treatment, low equipment stability and production efficiency, stability and production Low efficiency and other problems, to achieve the effect of reducing auxiliary man-hours, small footprint, and high versatility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

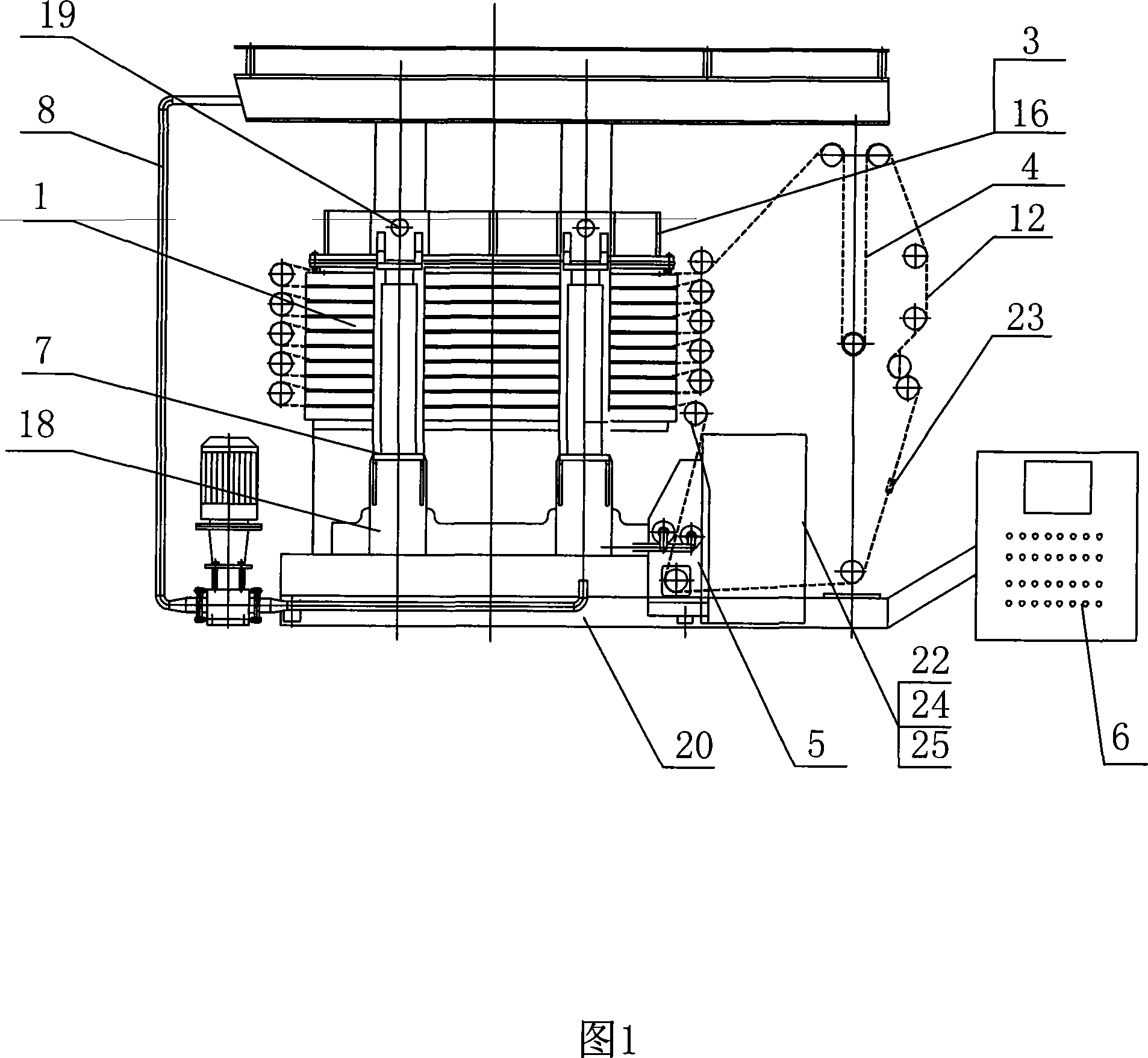

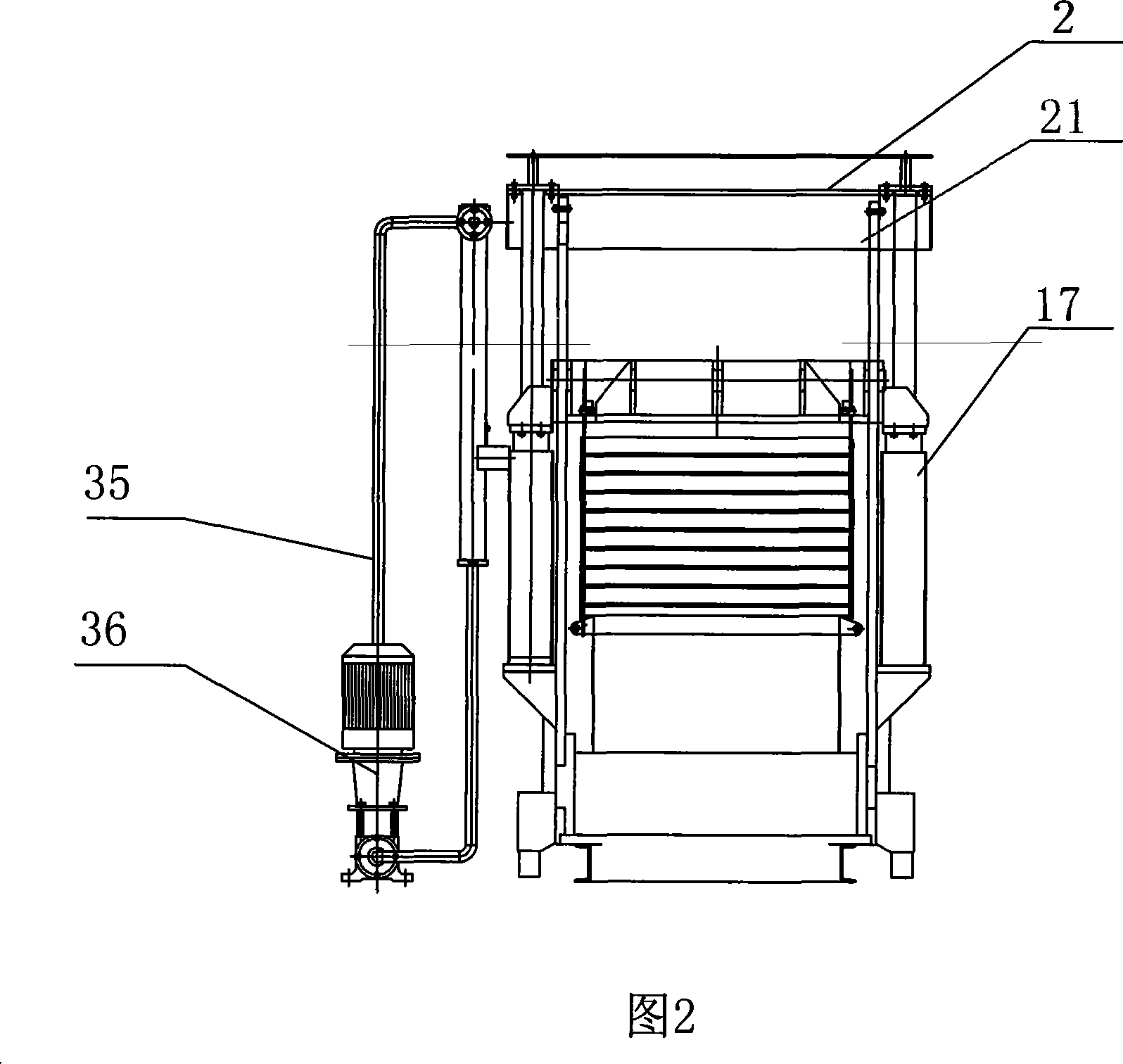

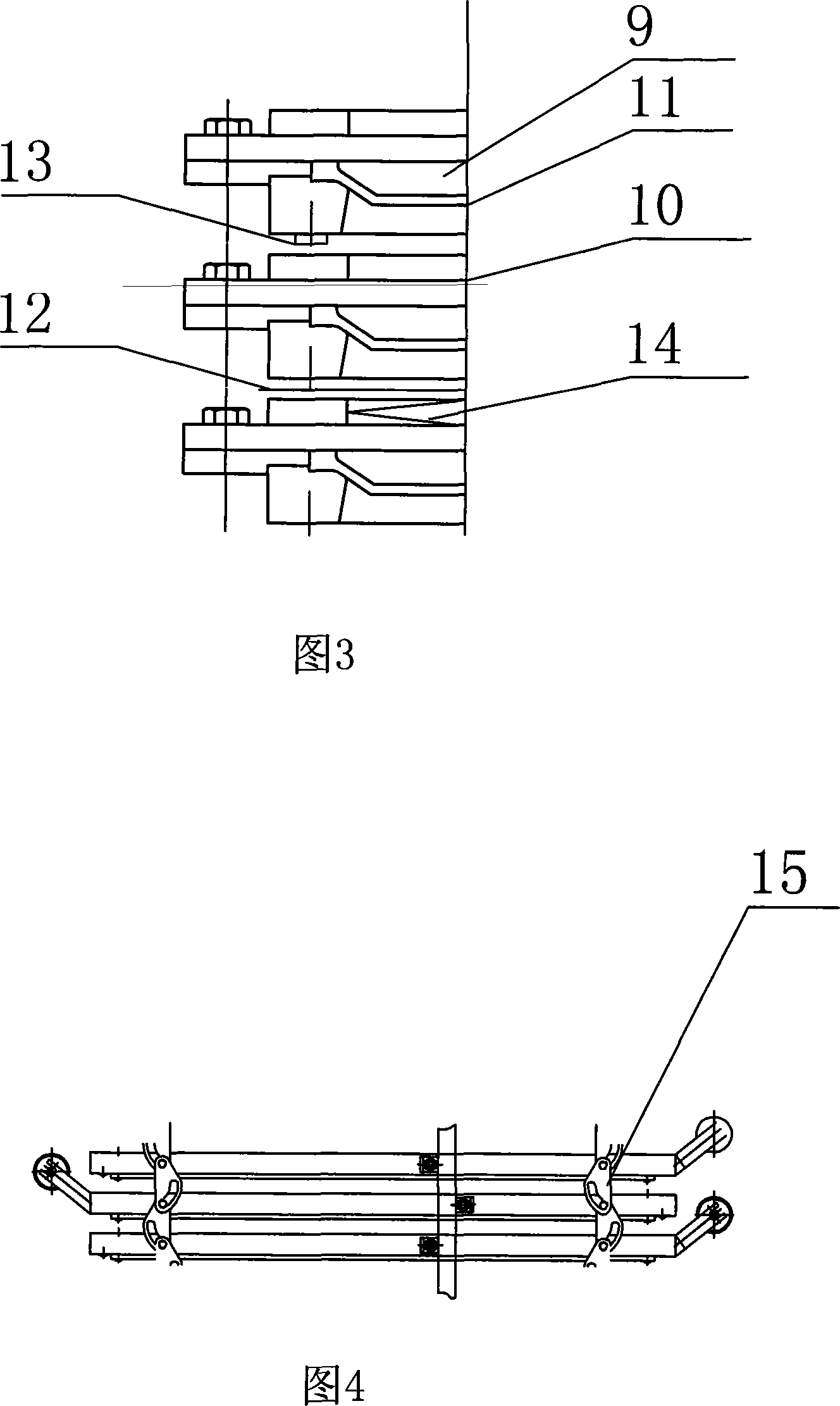

[0043] The technical solution of the present invention will be further specifically described below in conjunction with the accompanying drawings.

[0044] Vertical fully automatic plate and frame filter press, including horizontal plate and frame group 1, main frame structure 2, plate and frame group opening and pressing device 3, filter cloth automatic cycle walking mechanism 4, filter cloth washing device 5, automatic control system 6. Hydraulic system 7, process piping system 8, etc.;

[0045] As shown in Figure 1 and 2, the horizontal plate frame group, the opening and pressing device of the plate frame group, the process pipeline system and the filter cloth are fixed on the main support structure, the filter cloth automatic circulation walking mechanism, the filter cloth washing device and the hydraulic pressure The system is set on the side of the filter press, and the main electric control cabinet of the automatic control system is set outside the equipment body.

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com