Salt-containing separating liquid system and its prepn process

A spacer fluid and system technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of poor rheological adjustment and control ability, narrow range of spacer fluid density, single performance and use, etc., and achieve strong weighting ability , solve the effects of cementing quality decline and wide density adjustment range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

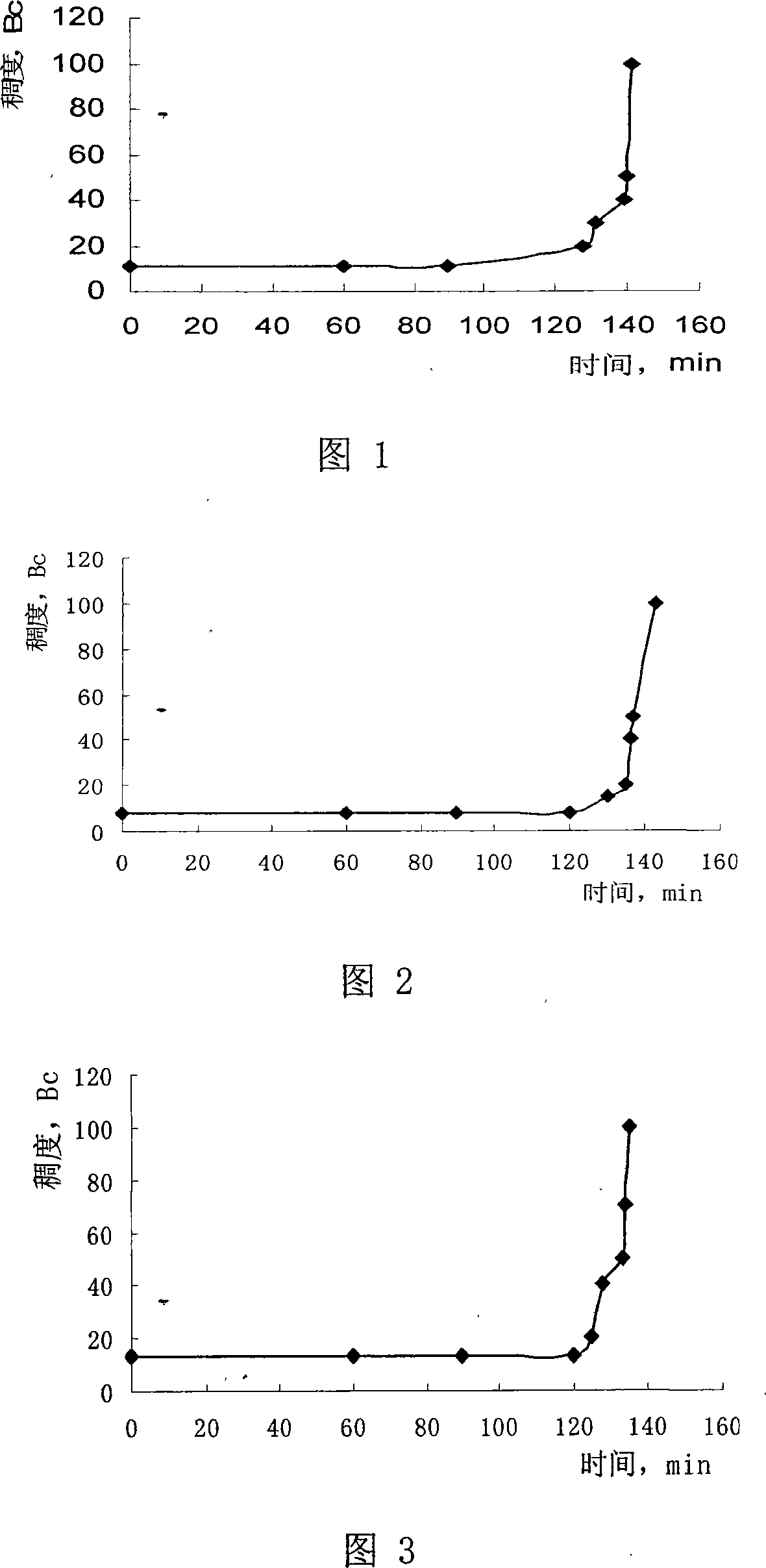

Embodiment 1

[0029] Embodiment 1. The salt-containing spacer fluid of the present invention is formulated into an undersaturated brine spacer system with 15% NaCl, and undersaturated brine spacer 1#-9# are prepared, and the basic performance in the room is measured. Take 100% clear water, first put in 4% modified bentonite and 0.24% Na 2 CO 3Stir for 2 hours, then prefabricated and hydrated for 24 hours; in the prefabricated clay base slurry, add 0.05 (0.05, 0.1, 0.2, 0.15, 0.15, 0.1, 0.15, 0.1)% tackifier, 0.2 (0.25, 0.25, 0.2, 0.2, 0.15, 0.15, 0.1, 0.1)% fluid loss reducer, 15% NaCl, 0.1 (0.3, 0.5, 0.5, 0.8, 0.8, 1.0, 1.2, 1.2)% flow regulator , each treatment agent is stirred evenly and then another is added; in the base liquid prepared above, add 33 (66.7, 100, 150, 200, 233, 266, 300, 333)% by weight under the condition of low-speed stirring The spar should be added slowly, and then stirred for 30 minutes after the addition, and the preparation of the 9 kinds of spacers is completed...

Embodiment 2

[0031] Example 2. The salt-containing spacer fluid of the present invention was prepared into a saturated brine spacer system with 35% NaCl, and saturated brine spacer 1#-9# were prepared, and the basic performance of the room was measured. Take 100% clear water, first put in 5% modified bentonite and 0.3% Na 2 CO 3 Stir for 2 hours, then prefabricated and hydrated for 24 hours; in the prefabricated clay base slurry, add 0.1 (0.1, 0.15, 0.15, 0.2, 0.2, 0.15, 0.15, 0.1)% tackifier, 0.2 (0.25, 0.25, 0.2, 0.2, 0.2, 0.15, 0.15, 0.15)% fluid loss reducer, 35% NaCl, 0.3 (0.5, 0.5, 0.8, 0.8, 1.0, 1.2, 1.4, 1.4)% flow regulator , each treatment agent is stirred evenly and then another is added; in the base liquid prepared above, add 33 (66.7, 100, 150, 200, 233, 266, 300, 333)% by weight under the condition of low-speed stirring The spar should be added slowly, and then stirred for 30 minutes after the addition, and the preparation of the 9 kinds of spacers is completed.

[0032] I...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com