Bearing channel automatic sorting linear transport mechanism

An automatic sorting and linear transmission technology, applied in sorting and other directions, can solve the problems of manual sorting accuracy and low efficiency, achieve product quality and quantity assurance, ensure transmission accuracy and reliability, and achieve high precision effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

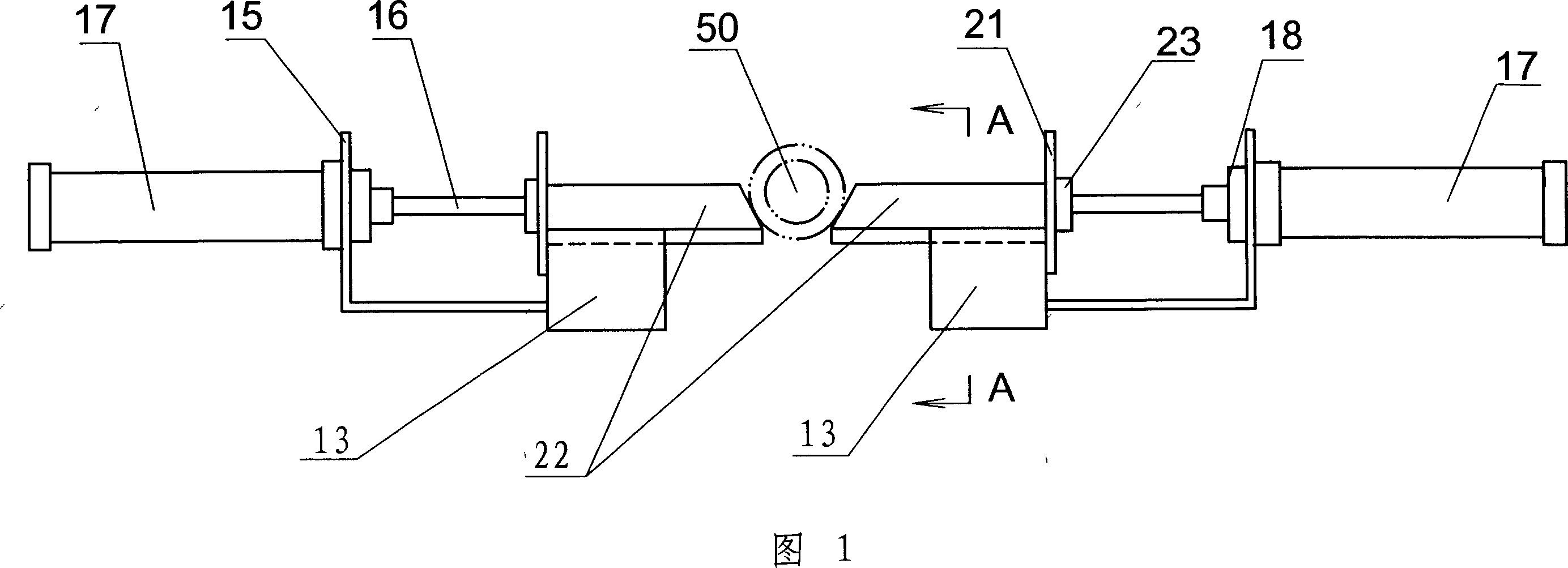

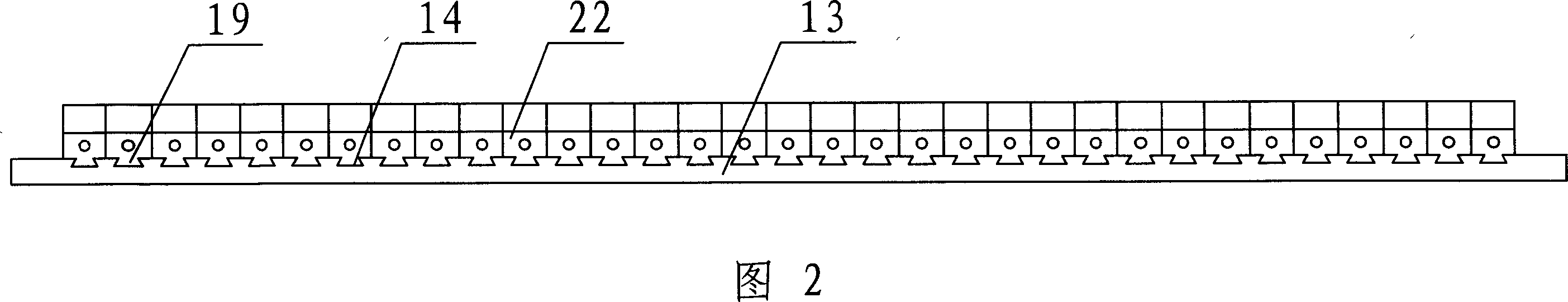

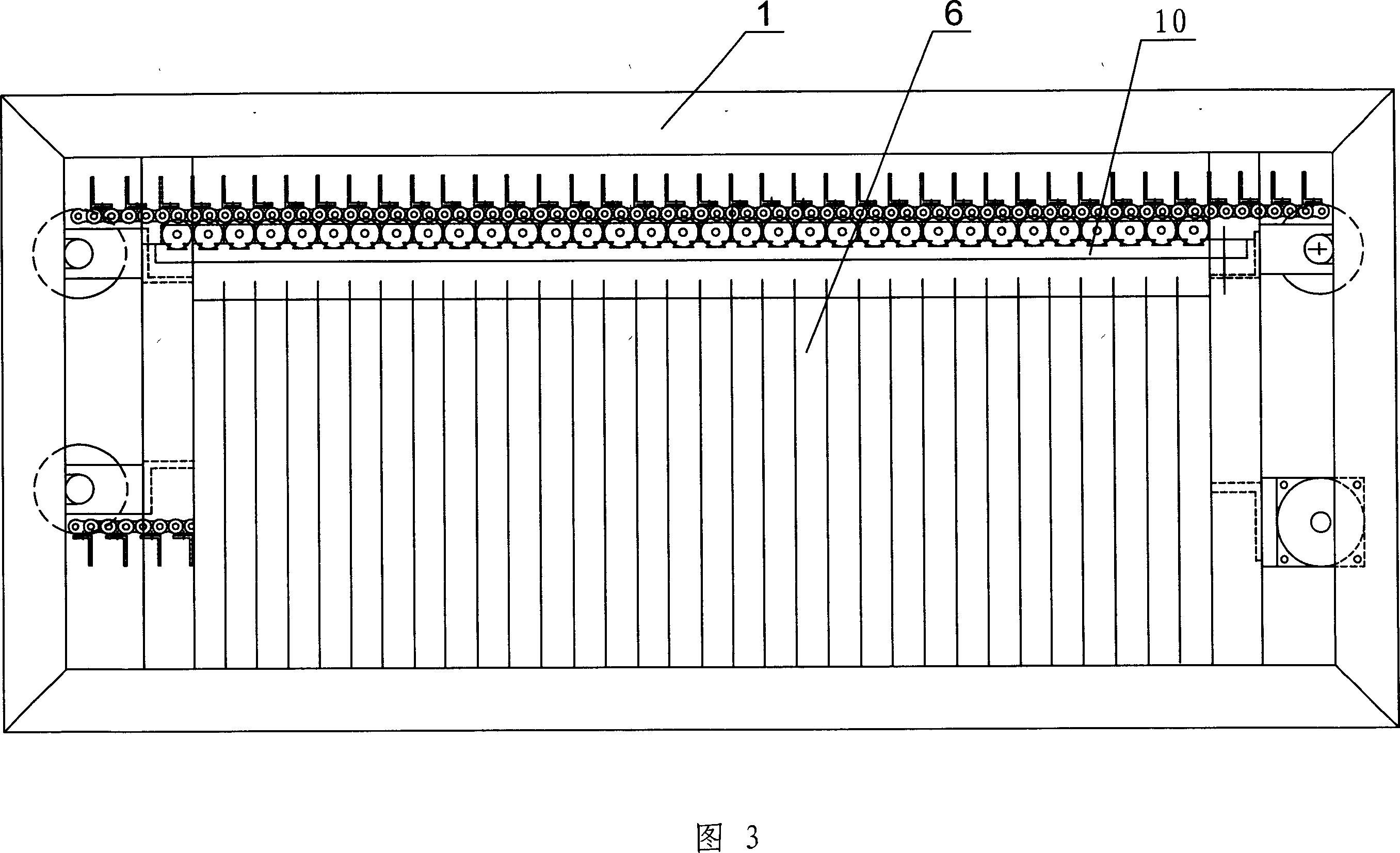

[0017] Bearing channel automatic sorting linear transmission mechanism, which is composed of slideway plate 13, slider 22, cylinder connecting plate 15 and cylinder 17, the slideway plate 13 and the slider 22 are tongue and groove fit, The front end of the slide block 22 is an inclined plane, and the described slideway plate 13 is welded with a cylinder connecting plate 15, and the described cylinder connecting plate 15 is fixed with a cylinder 17 by a nut 18, and the other part of the piston rod 16 in the described cylinder 17 is One end passes through the positioning plate 21 and is screwed into the slide block 22, and the three are fastened with a nut 23, and the positioning plate 21 plays a positioning role.

[0018] The cooperation between the slideway plate 13 and the slider 22 may be a dovetail groove fit, a T-shaped groove fit, a cylindrical groove fit, or a concave-convex groove fit.

[0019] The above-mentioned bearing channel automatic sorting linear transmission me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com