Improved apparatus and method of intraocular pressure determination

A pressure, eyeball technology, used in tonometers, eye testing equipment, eye examinations, etc., to solve problems such as inability to measure or correct corneal thickness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] A patient undergoing LASIK surgery for myopia of -8 diopters (-8D) had a preoperative central corneal thickness of 452 microns. Laser in situ keratomileusis procedure. The intraocular pressure measured six months after laser in situ keratomileusis was 16 mmHg as measured by Goldmann tonometry. The uncorrected intraocular pressure determined by the present invention was also 16 mmHg. A pachymeter showed a central corneal thickness of 347 microns. The corrected intraocular pressure determined by the present invention is 25 mmHg. In this case, the invention demonstrates that the intraocular pressure is higher than it would otherwise be; possibly masking glaucoma. Normal intraocular pressure ranges from 12 to 21 mmHg.

Embodiment 2

[0039] The patient's intraocular pressure, as measured by a Goldmann tonometer, was 19 mmHg for a routine eye examination. The uncorrected intraocular pressure as determined by the present invention was also 19 mmHg. Pachymetry showed a central corneal thickness of 485 microns. Corrected intraocular pressure as determined by the present invention was 23 mmHg. In this case, the invention demonstrates that the intraocular pressure is higher than it would otherwise be; glaucoma is masked.

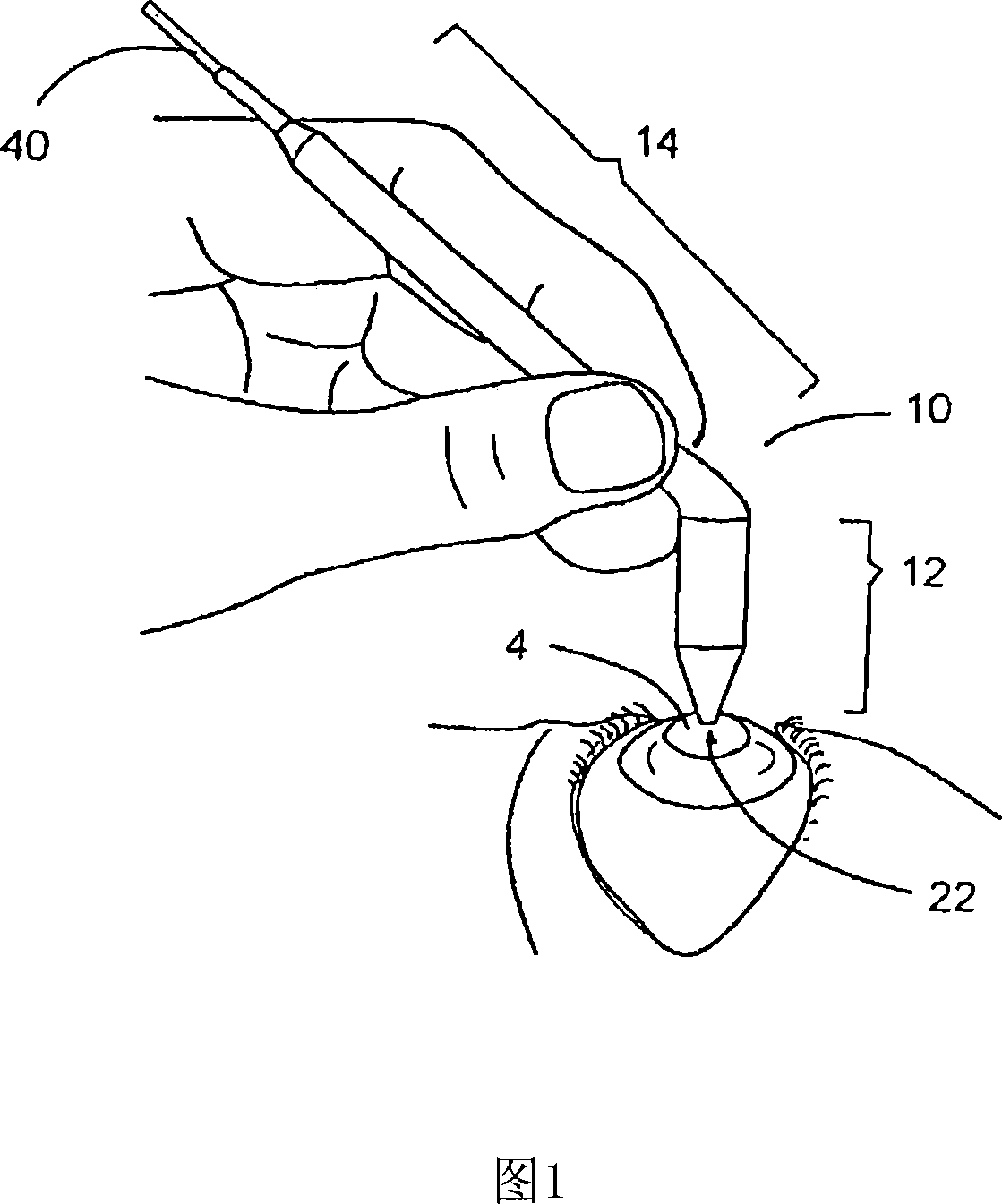

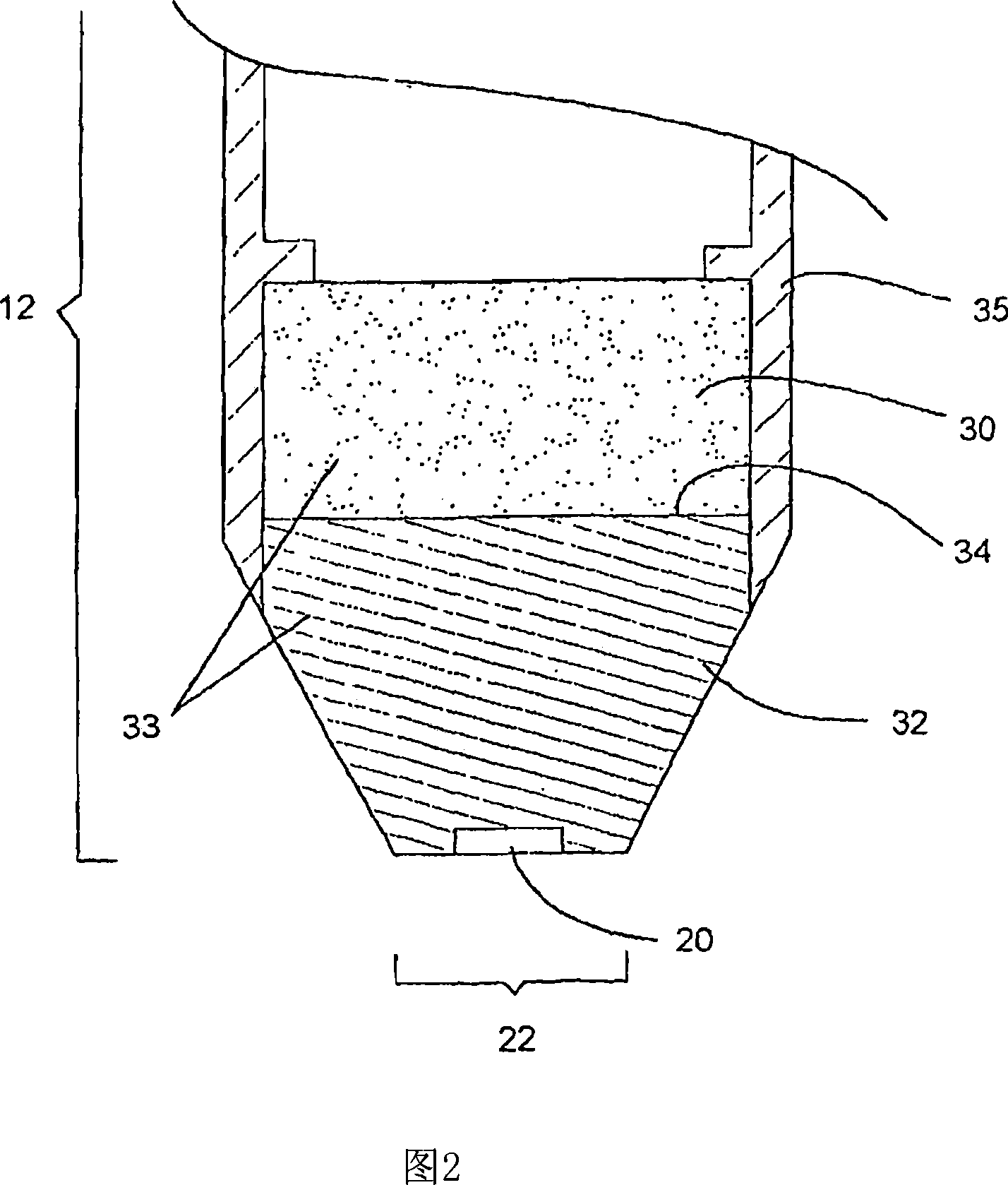

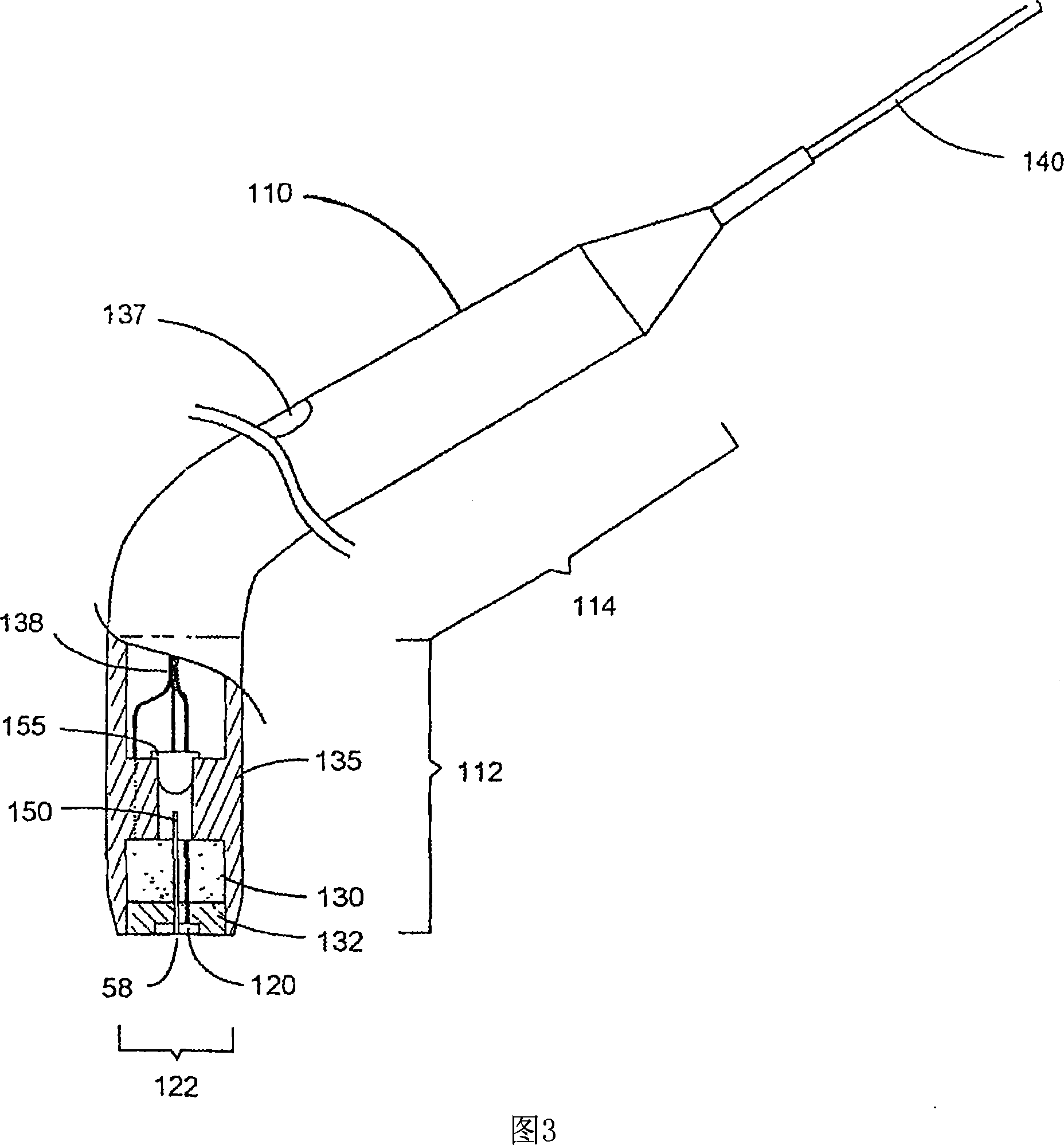

[0040] The device of the present invention described and shown herein is a novel device for simultaneously measuring pressure and surface thickness of a fluid-filled eyeball at the same applanation site, where at least part of the applanation surface is an ultrasound transducer. The method using the device involves simultaneous measurement of intraocular pressure and surface thickness of a fluid-filled eyeball at the same applanation site for more accurate determination of intraocular pressu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com