Digital control continuous liquid filling machine

A technology of filling machine and numerical control device, which is applied in the field of numerical control continuous liquid filling machine, can solve the problems of long filling time interval, short filling time and low production efficiency, and achieve the goal of prolonging filling time and improving production efficiency Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

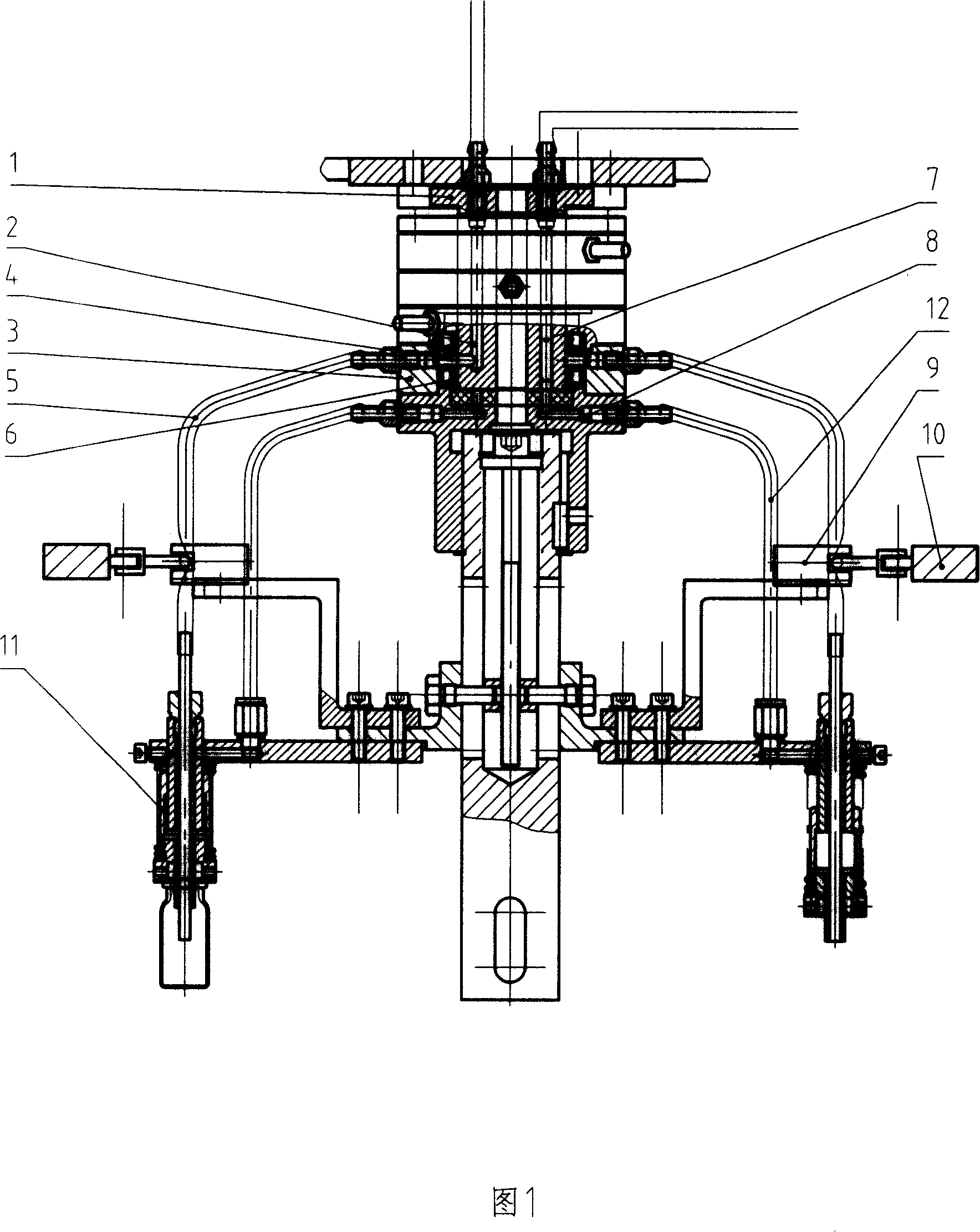

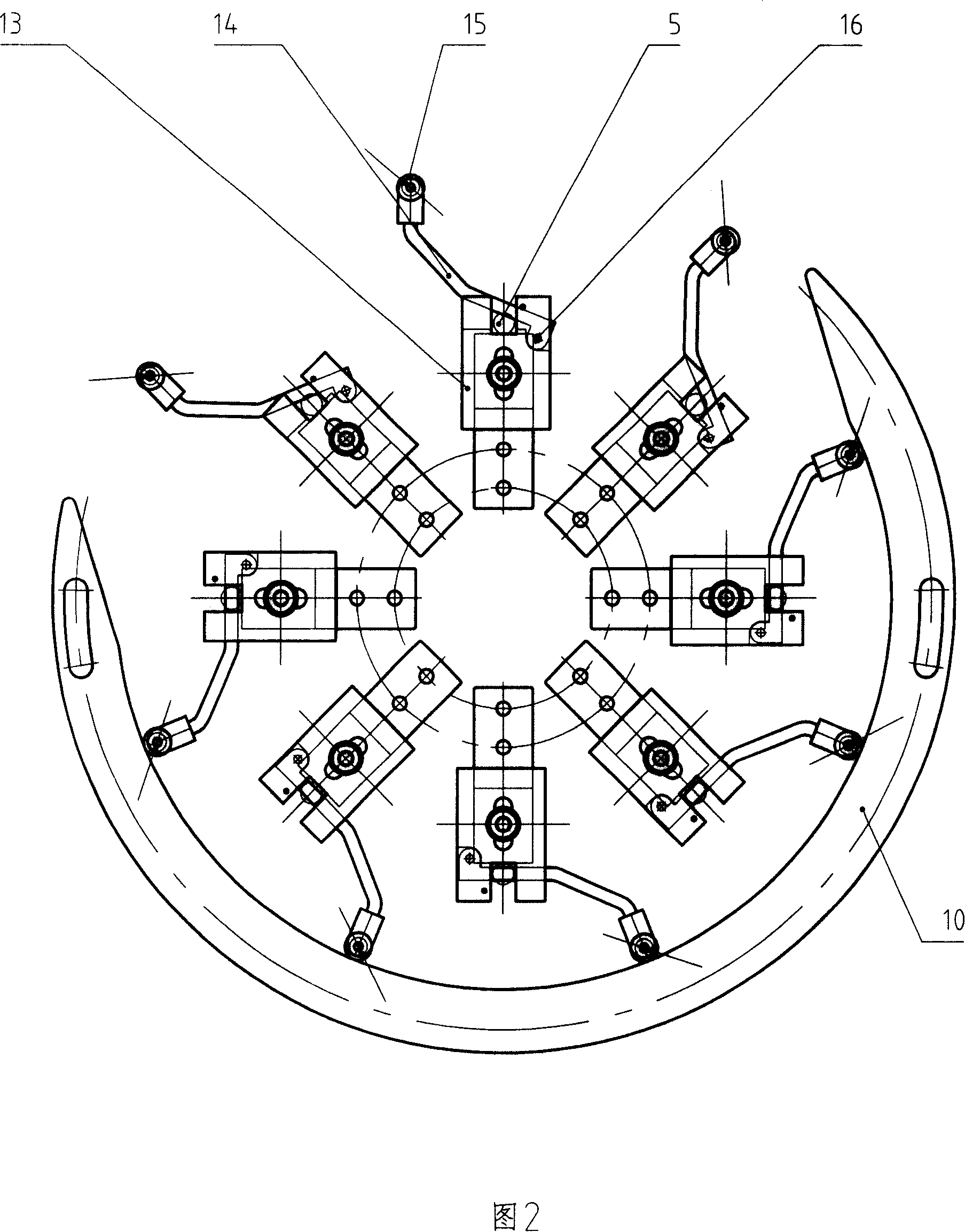

[0012] Specific embodiment 1, accompanying drawing has provided a kind of specific structure of the present invention, referring to Fig. 1, a kind of numerical control continuous liquid filling machine, it comprises numerical control device, power and transmission device, bottle feeding device, filling device, nitrogen charging The device and the stoppering device are special in that the filling device has a stator (1), and the stator (1) has a liquid passage chamber (2), and the liquid passage chamber (2) is connected with the liquid supply pipe of the peristaltic pump, and has The rotor (3) matched with the stator (1), the rotor (3) has an annular liquid passage chamber (4) communicating with the liquid passage chamber (2) on the stator (1), the annular liquid passage chamber (4) ) is connected with the liquid pipe (5) on the filling head (11), and there is a sealing ring (6) between the stator (1) and the rotor (3). On the stator (1), there is a nitrogen filling cavity (7) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com