Device and method for manufacturing glass shaping product

A manufacturing device and manufacturing method technology, applied in the field of glass molding manufacturing equipment, can solve the problems of easy generation of bubbles or streaks, unstable optical properties of glass preforms, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0061] [Glass molded product manufacturing equipment]

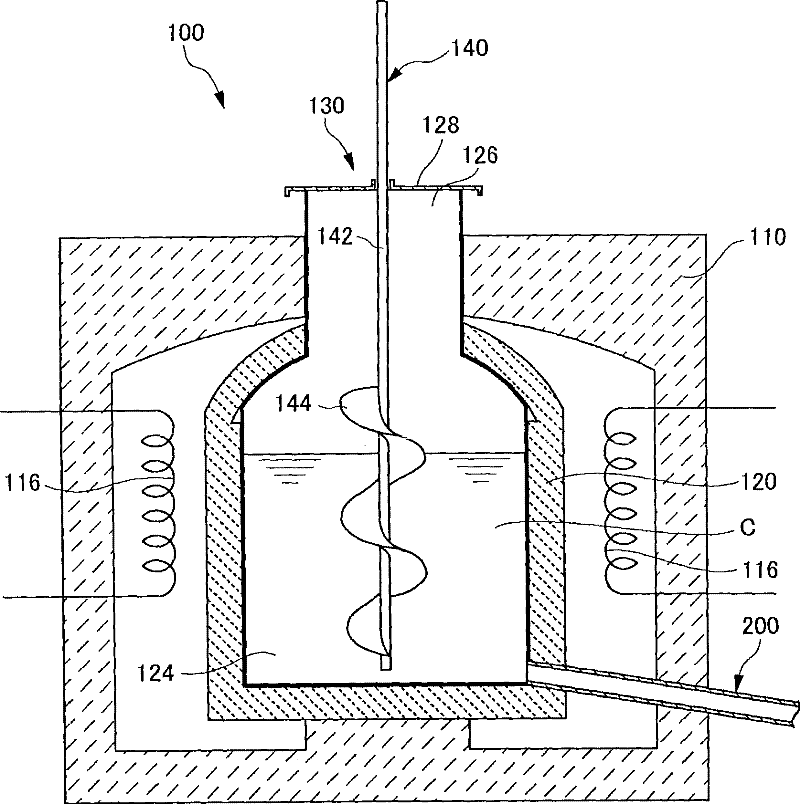

[0062] like figure 1 As shown, the glass molded product manufacturing apparatus 10 includes: a melting device 100 for melting glass raw materials, a flow-down device 300 for flowing down molten glass melted by the melting device 100 , and a glass forming device for forming molten glass that flows down through the flow-down device 300 400.

[0063] like figure 1 As shown, the glass molded product manufacturing apparatus 10 further includes: a transfer device 800 for transferring the glass molded product E formed by the glass forming device 400; a first transfer device 500 for transferring the glass formed product E formed by the glass forming device 400 to The conveying device 800; the weight sorting device 700 measures the weight of the glass molded product E conveyed by the conveying device 800, and sorts the weight of the glass molded product E conveyed by the conveying device 800; E is transferred to the weight sort...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com