Tyre explosion-proof monitoring alarm

A technology for alarms and tires, applied in alarms, automobile tire testing, instruments, etc., can solve the problems of low detection accuracy of alarm devices, single function, and easy damage to detection mechanisms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

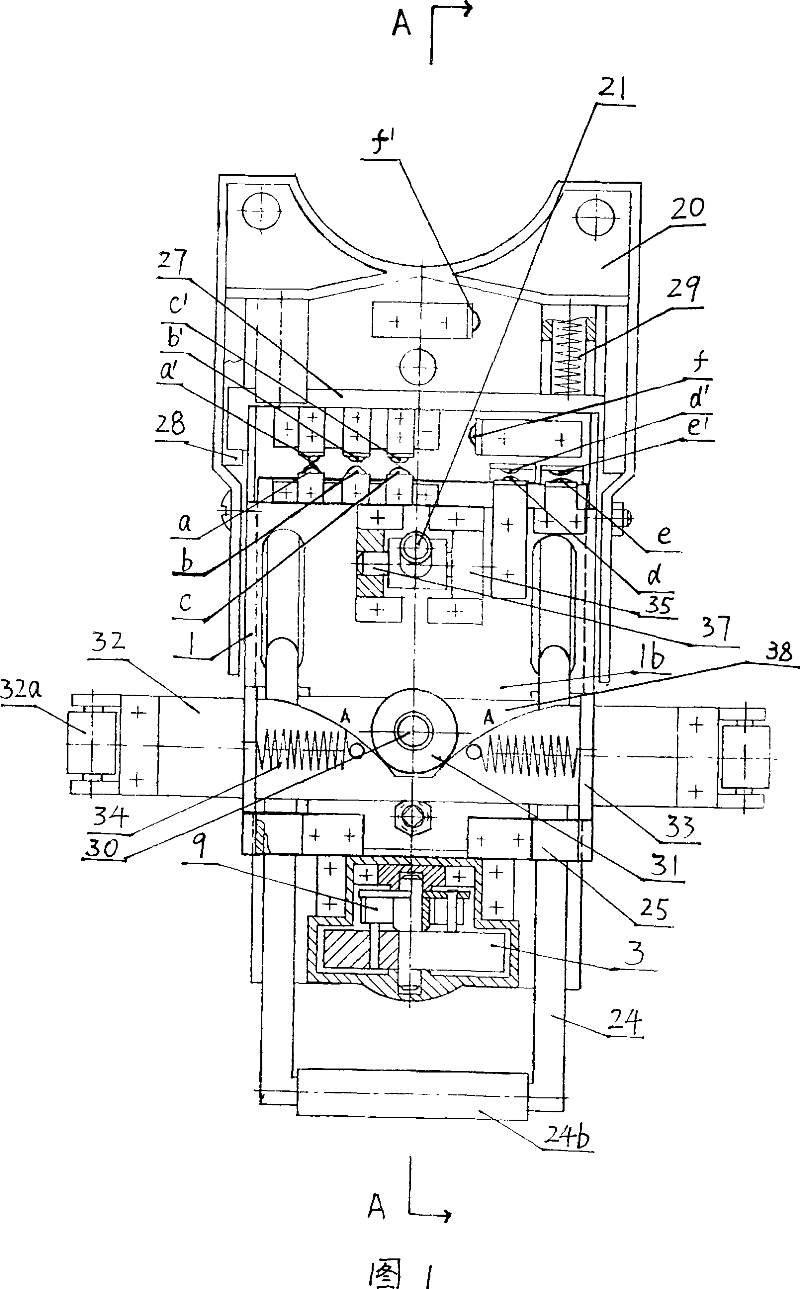

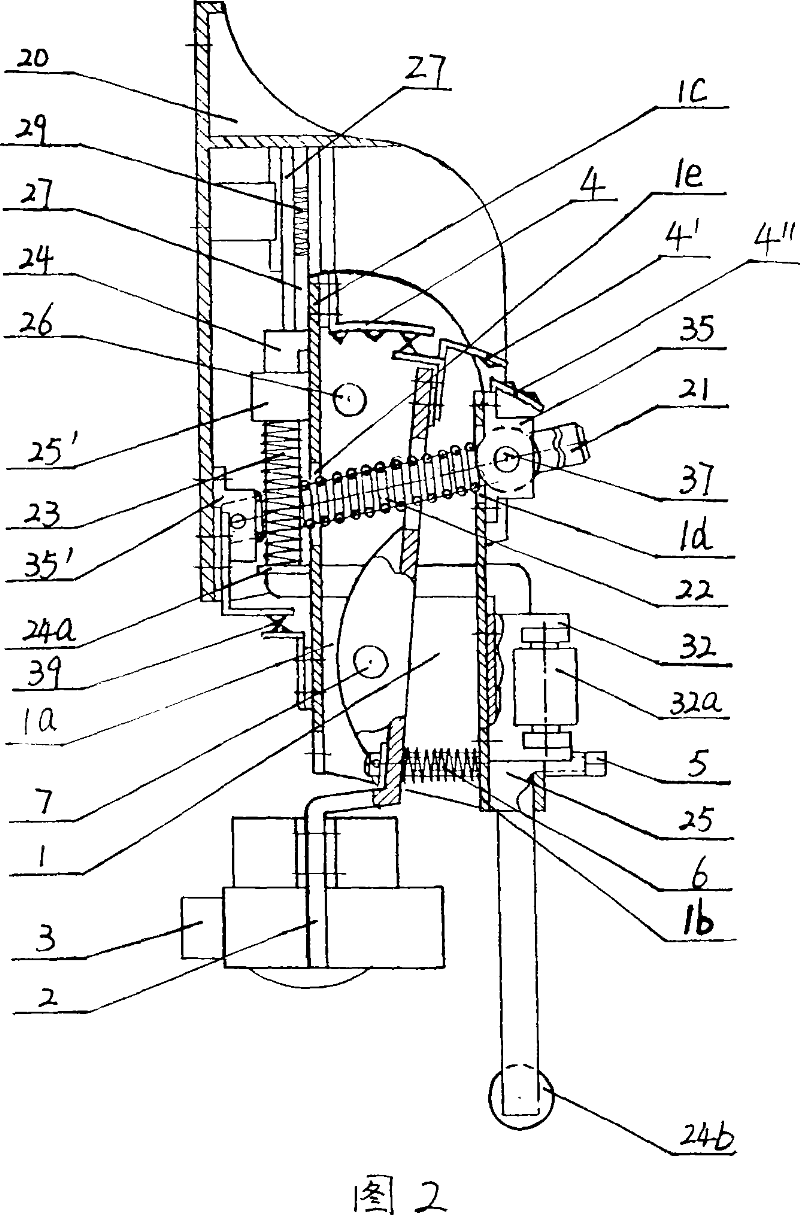

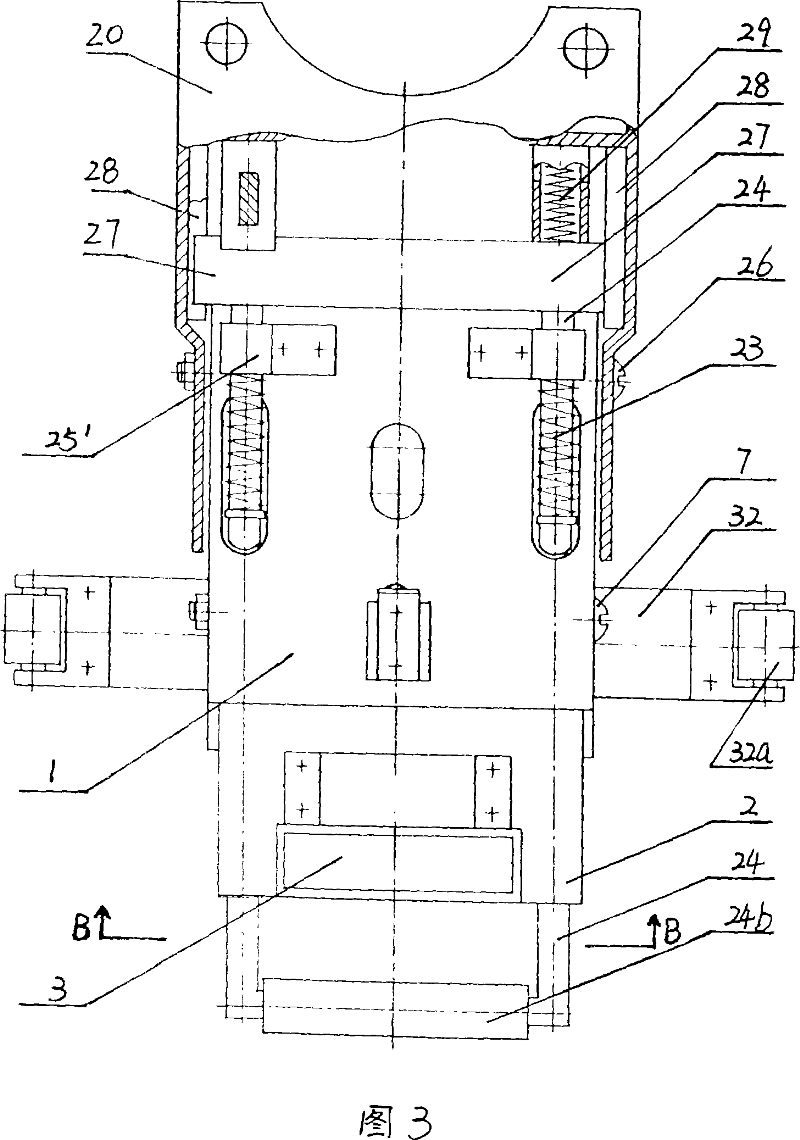

[0021] As shown in Figures 1 to 8, the tire explosion-proof monitoring and alarm device provided by the present invention is composed of a monitoring mechanism, a rotating mechanism and a security mechanism, wherein:

[0022] Monitoring mechanism (see Fig. 1, Fig. 2) is made up of main frame 1, sensing support arm 2, probe 3 and contact switch group, described main frame 1 upper and lower ends are opened, and the side vertical plate 1a of this main frame 1 is connected The shaft 7 is connected to the middle part of the sensing support arm 2, and a square head screw 5 is installed on the sensing support arm 2 below the connection shaft 7, and one end of the square head screw 5 passes through the front vertical plate 1b of the main chassis 1 The lower part, and threadedly connected with it, is covered with a guarantor spring 6 on the lag screw 5, and the guarantor spring 6 is located between the front vertical plate 1b and the sensing support arm 2; the sensing support arm 2 is l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com