Single-group wheel-track combined type domestic rice combine

A combined harvester and compound technology, applied in the direction of harvesters, applications, cutters, etc., can solve problems such as unsuitable for harvesting operations, easy to get stuck in mud, and unsatisfactory performance of the walking mechanism

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

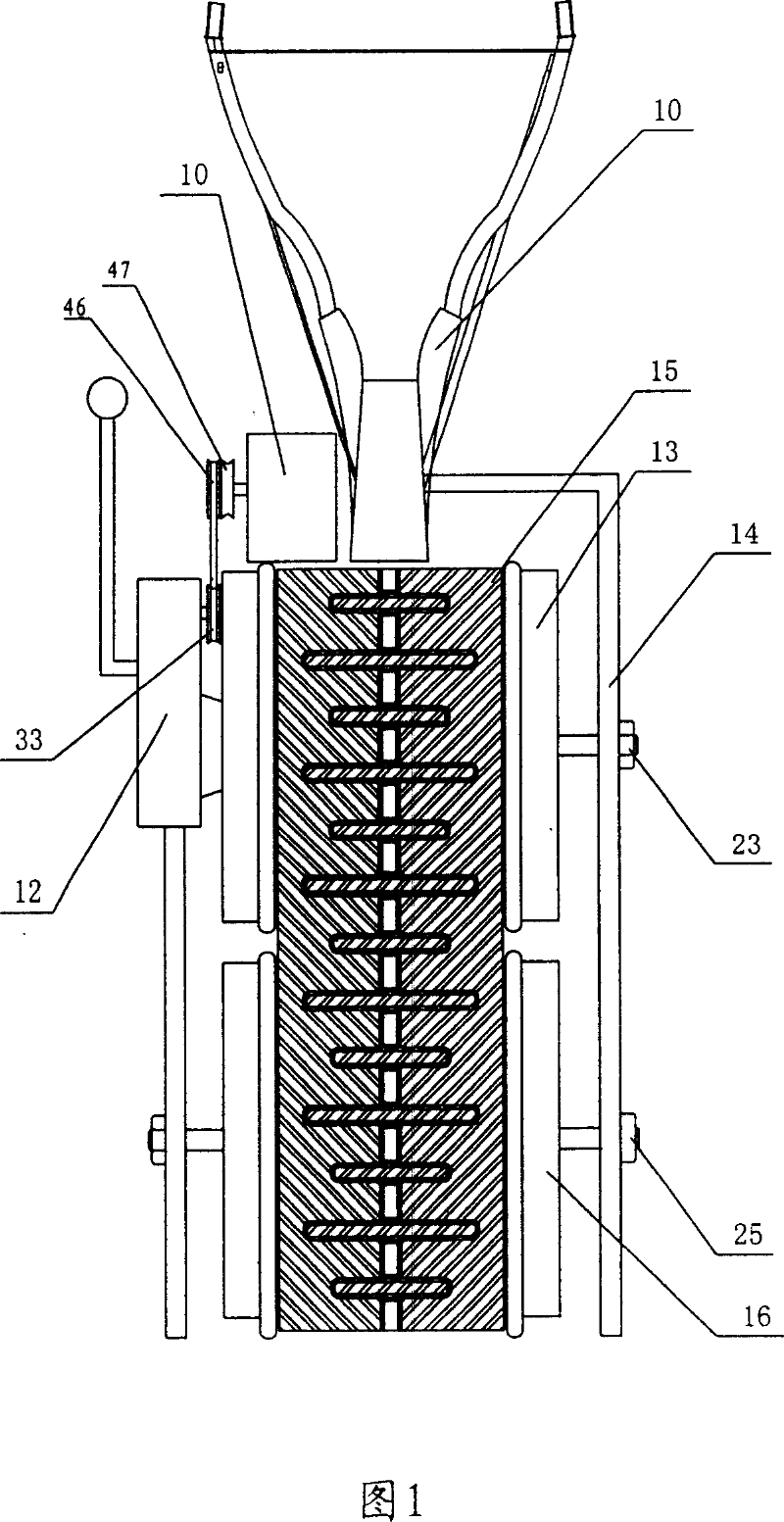

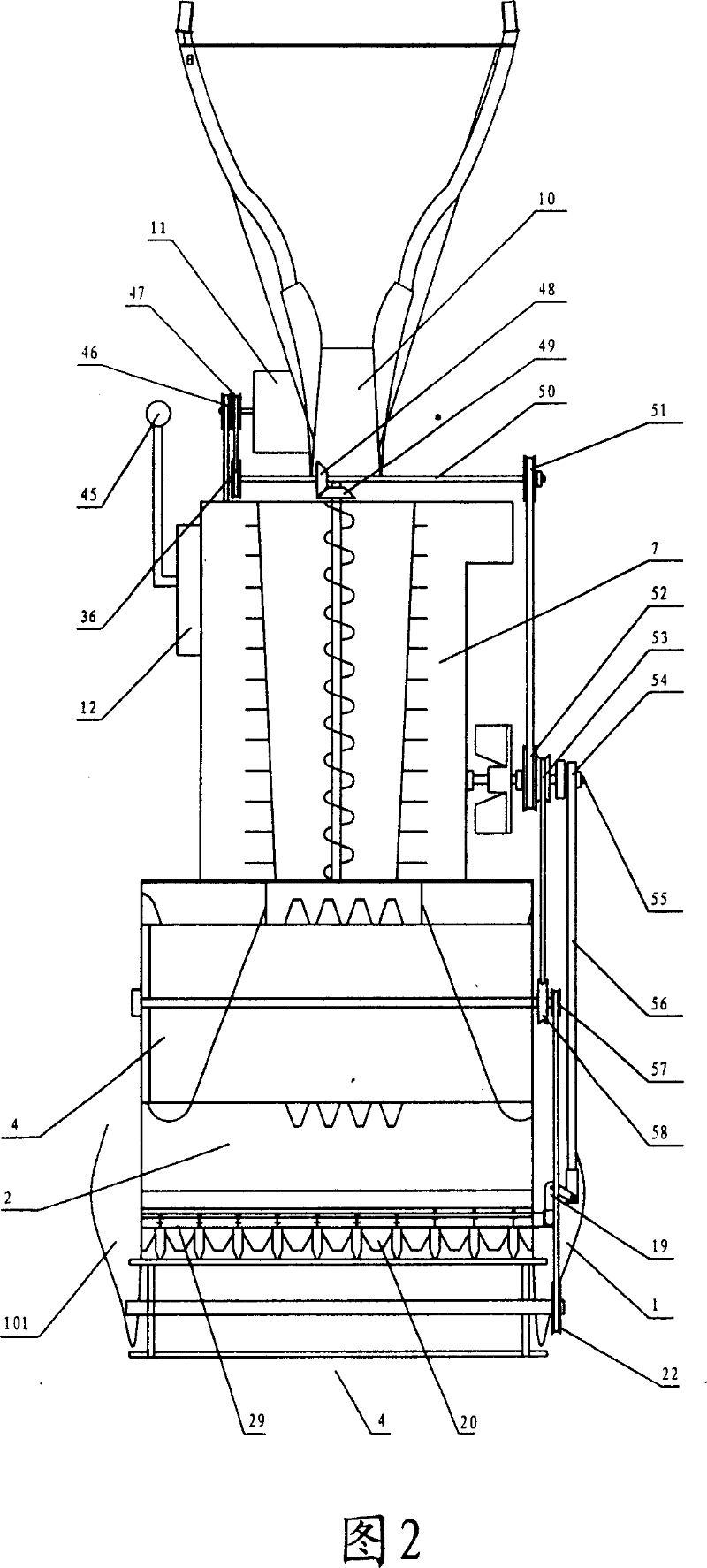

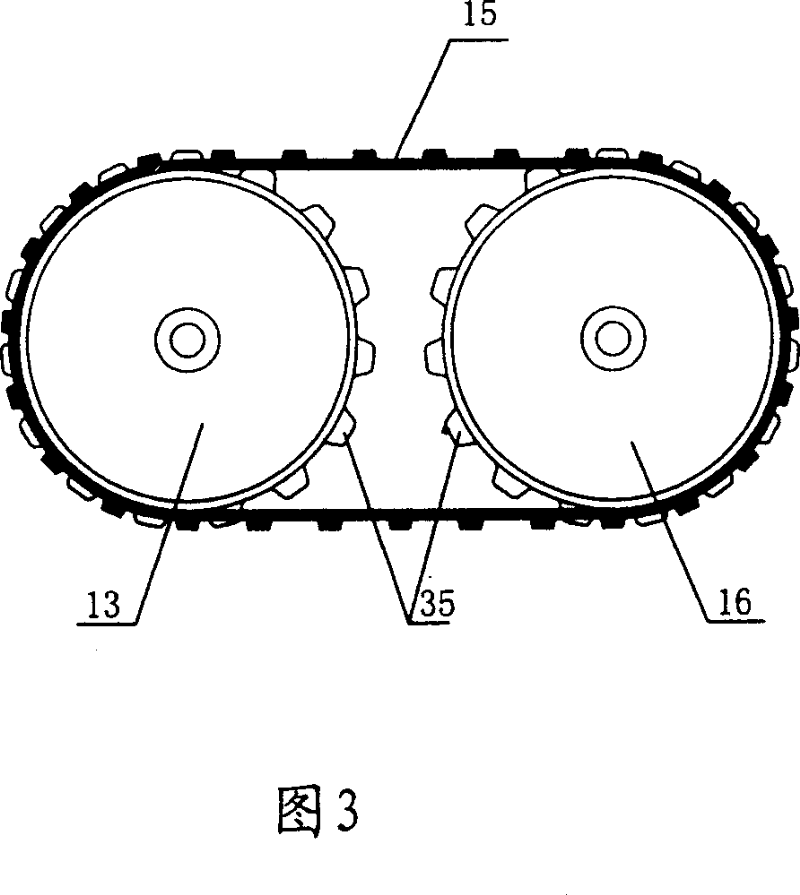

[0044] According to Fig. 2, Fig. 5 and the rice combine harvester of above-mentioned structure, comprise chassis 14, frame 5, grain dividing device 1, grain raking device 3, harvesting table 2, ear auger 4, threshing device 7, grain raising device 9. Power 11; as shown in Figures 1, 3, and 4, the power 10 is fixedly installed on the rear end of the chassis 2, and its main shaft pulley 46 drives the gearbox pulley 33 through the V-belt, and the gearbox has forward, reverse, and neutral gears. position, by the gear control handle 45 to control the half shaft 23 gearshift, the active travel wheel 13 on the half shaft 23 and the driven travel wheel 16 installed on the driven travel shaft 25, the outer periphery has gear teeth 35, and the suit Flat crawler belt 15 is arranged, and tooth hole 38 on the flat crawler belt 15 meshes with the gear teeth 35 of two traveling wheels to move, and the climbing tooth 34 that crawler belt surface is provided with rolls and walks.

[0045]With ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com