Electromagnetically vibrating precise seeder

An electromagnetic vibrator and precision seeding technology, which is applied to planter parts, seed treatment methods, etc., can solve the problems of insufficient seeding accuracy and achieve a low rate of damage to seedlings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with drawings and embodiments.

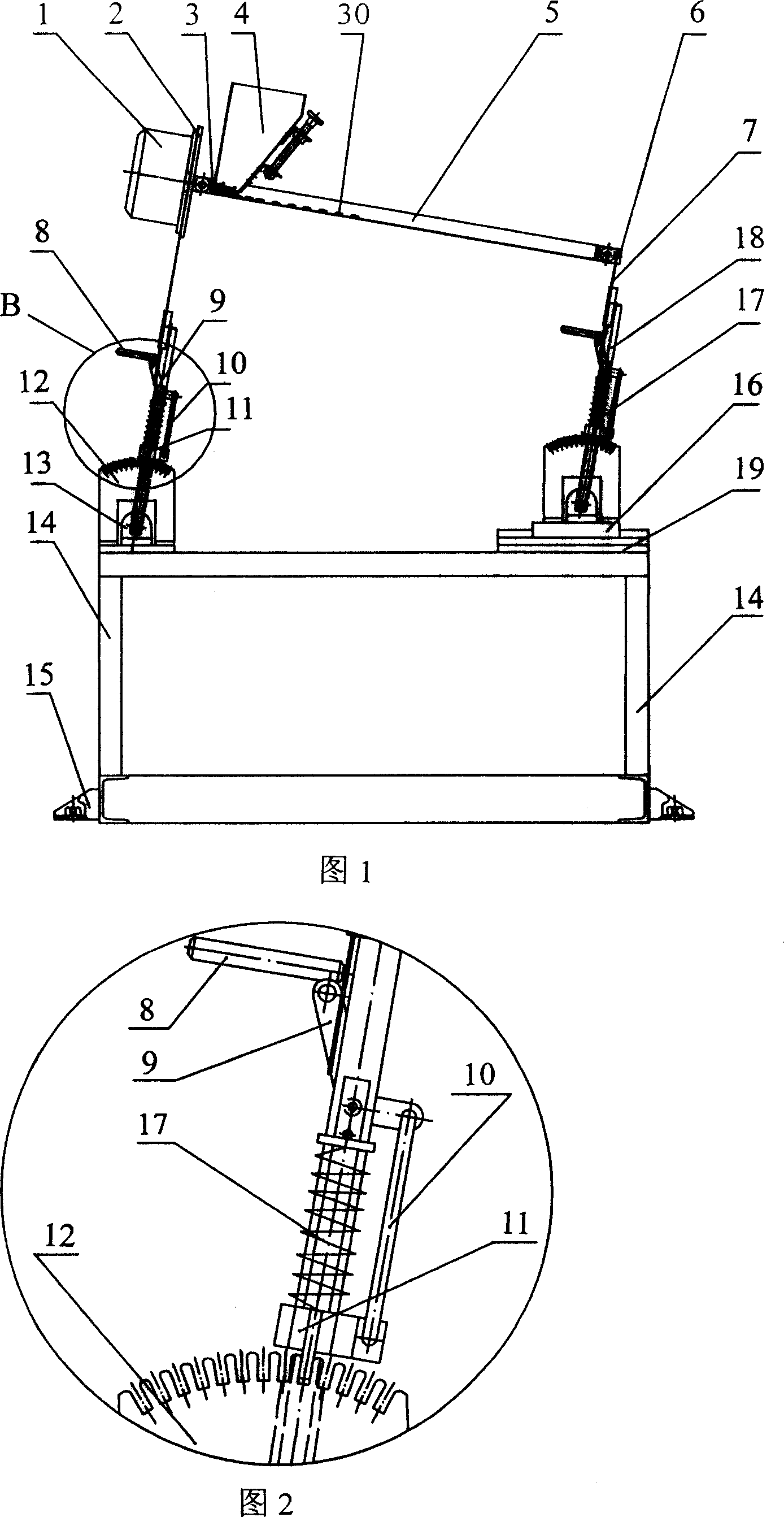

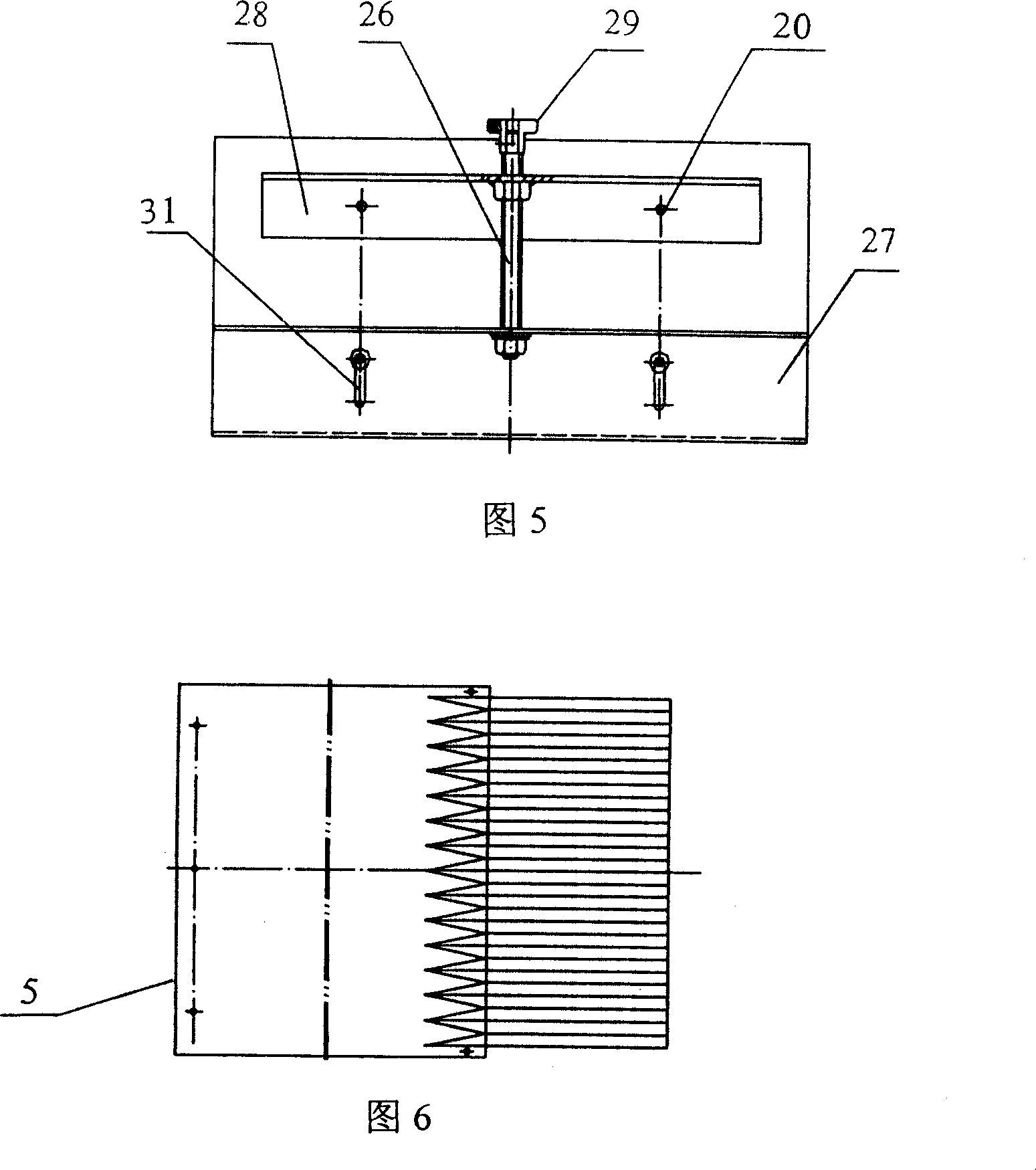

[0015] As shown in Fig. 1, Fig. 2 and Fig. 3, the electromagnetic vibrator 1 of the present invention is fixedly installed on the seat plate 2, and the vibrating plate 5 is connected with the seat plate 2 through a pin shaft; two leaf springs 7 form a group, and a group of plate One end of spring 7 is installed on the seat plate 2, and the other end is installed on the vertical shaft 18; One end of another group of plate springs 7 is installed on one end of the vibrating plate 5 away from the electromagnetic vibrator 1, and the other end is installed on another vertical shaft 18; The angle positioning seat 12 on one side of the electromagnetic vibrator 1 is installed on the vibration frame 14, and the angle positioning seat 12 on the other side of the electromagnetic vibrator 1 is installed on the fixed seat 19 of the vibration frame 14 through the slider 16. Two vertica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com