Disassembling-free lattice beam mould

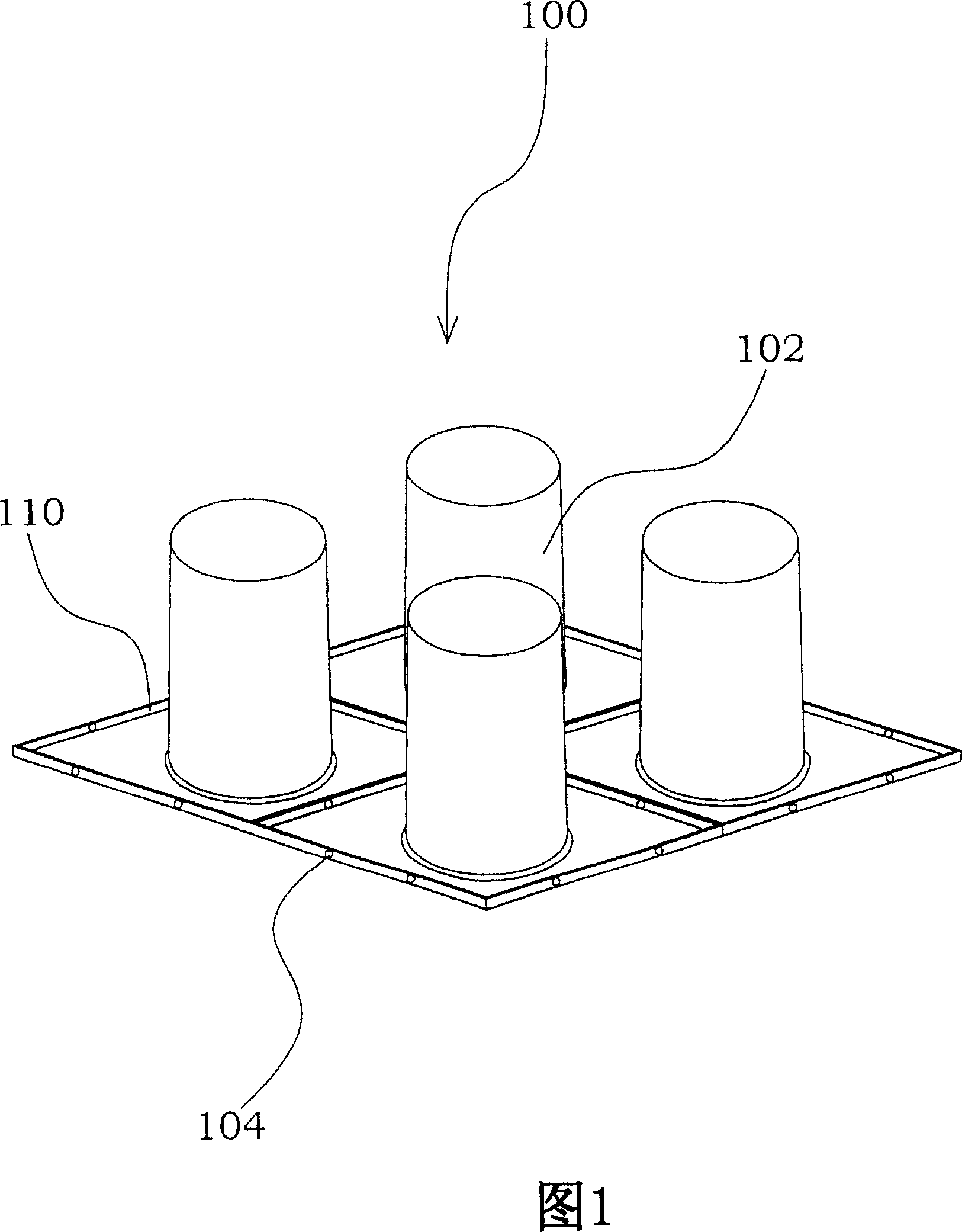

A technology of lattice beams and moulds, which is applied in the field preparation of formwork/formwork/work frames, building components, construction, etc., and can solve problems such as inability to connect with other moulds, deformation, rough appearance and inner surface, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The invention provides a dismantling-free lattice beam mold to prevent the mold from loosening under pressure, increase the height of the mold or adjust the level accuracy, and what's more, it can replace the raised floor on the mold of the known technology. The detailed description is as follows, and the preferred embodiment is only for illustration and not intended to limit the present invention.

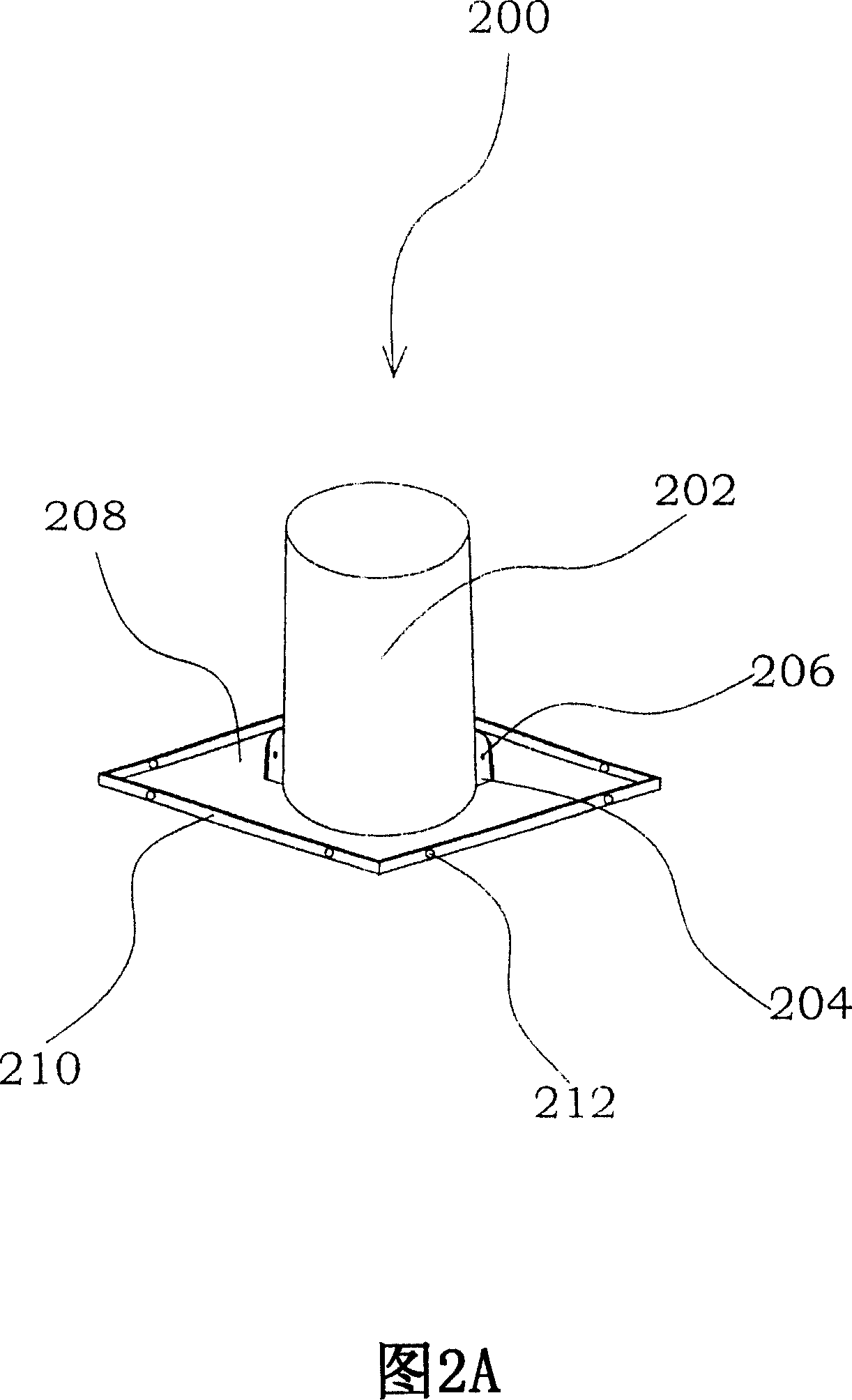

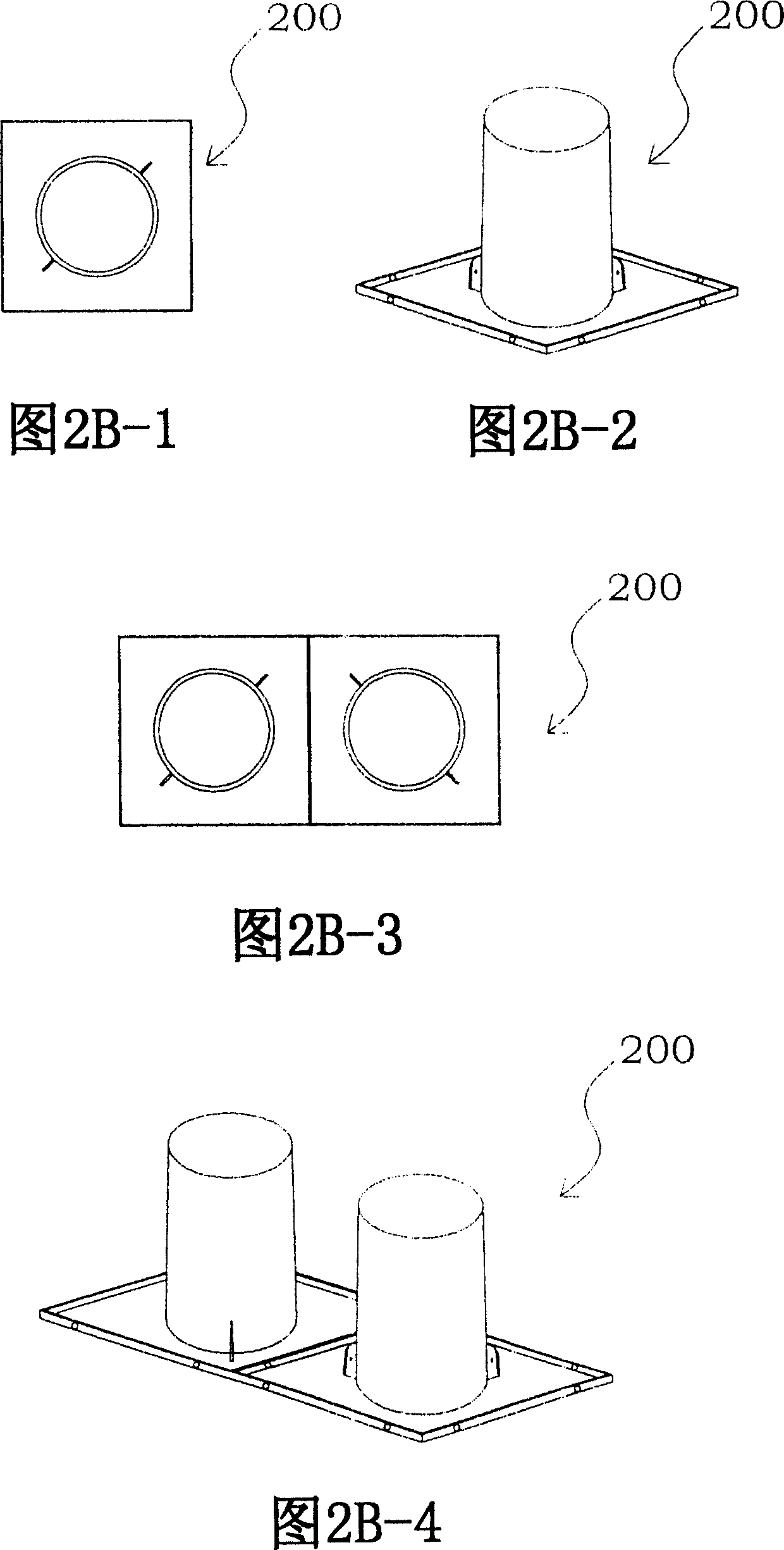

[0046] Please refer to FIG. 2A , which is a three-dimensional schematic diagram of an implementation form of a non-dismantling lattice beam mold according to the first embodiment of the present invention, which is a first hollow cylinder 202, and the bottom of the first hollow cylinder 202 extends laterally outward. A base 208 is provided. In addition, at least one wing 204 is disposed on the outer edge of the first hollow cylinder 202 . In this embodiment, the first hollow cylinder 202 may be a frusto-conical design. At least one hole 206 is provided on the wing plate 204...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com