Non-uniform flexible anchoring baffle pond inverted arch bottom plate structure

A stilling pond and bottom plate technology, applied in water conservancy projects, marine engineering, coastline protection, etc., can solve the problems of anchoring steel bars in the center plate being wasted, easy to yield, and not playing a major role

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to enable those skilled in the art to better understand the solution of the present invention, the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

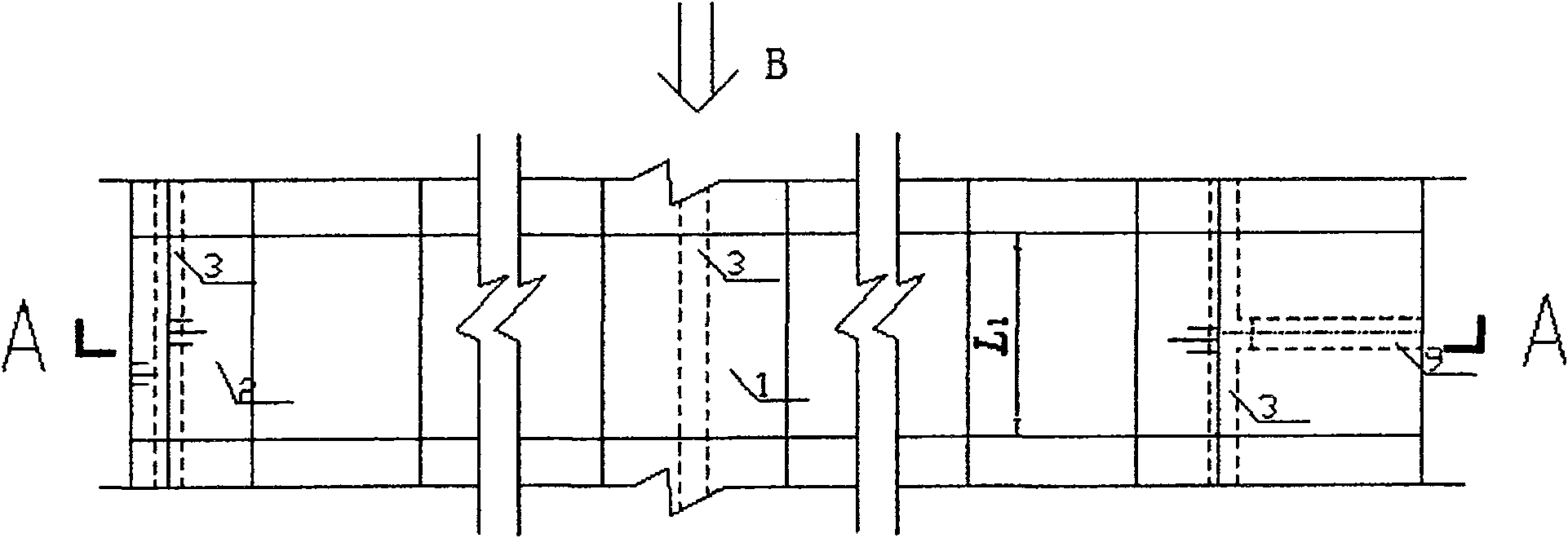

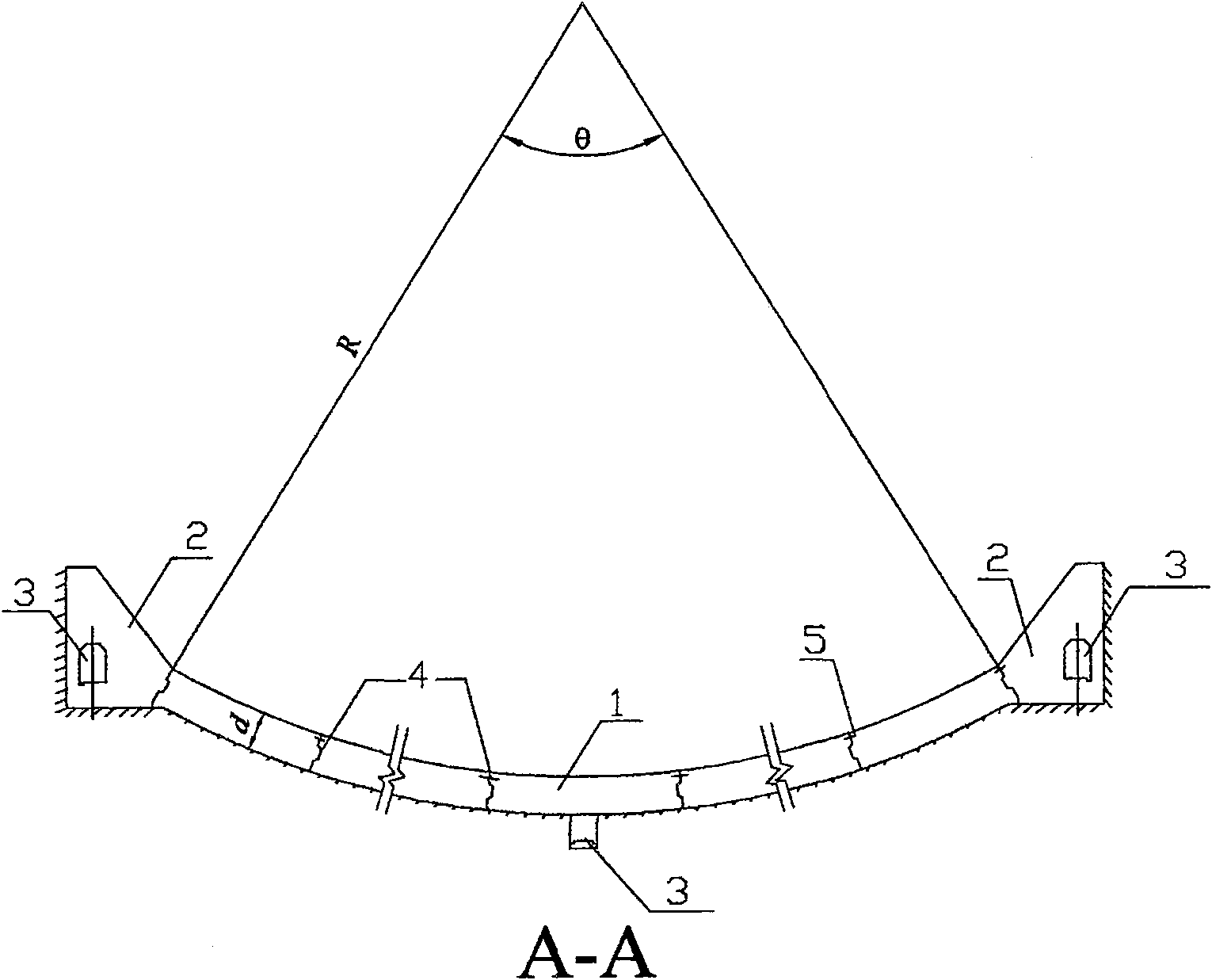

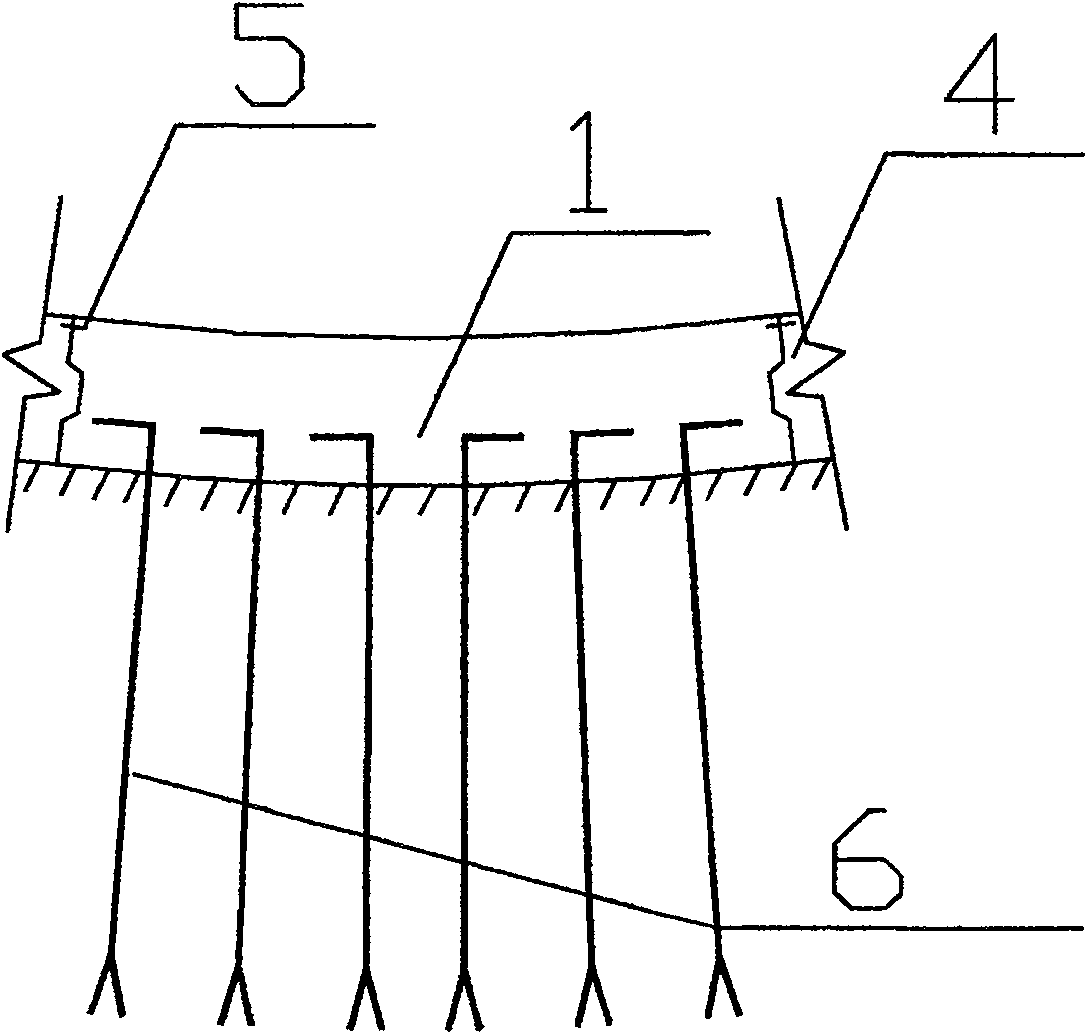

[0016] figure 1 The plane layout diagram of the anti-arch floor structure of the non-uniform flexible anchor stilling pond provided by the present invention, figure 2 The sectional view along the A-A line of the anti-arch floor structure of the non-uniform flexible anchor stilling pond provided by the present invention, image 3 Schematic diagram of the arrangement of anchoring steel bars for the anti-arch bottom plate in the anti-arch bottom plate structure of the non-uniform flexible anchor stilling pond provided by the present invention, Figure 4 It is a schematic diagram of the arrangement of flexible anchoring steel bars on the anti-arch floor structure of the non-uniform flexible anchoring stilling pond provided by the present inven...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com