Printing medium mechanism unit for printer

A printing medium and tension mechanism technology, applied in printing devices, printing, etc., can solve problems such as limiting the printing quality of the printer and affecting the printing quality of the printer, and achieve the effect of improving the printing quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

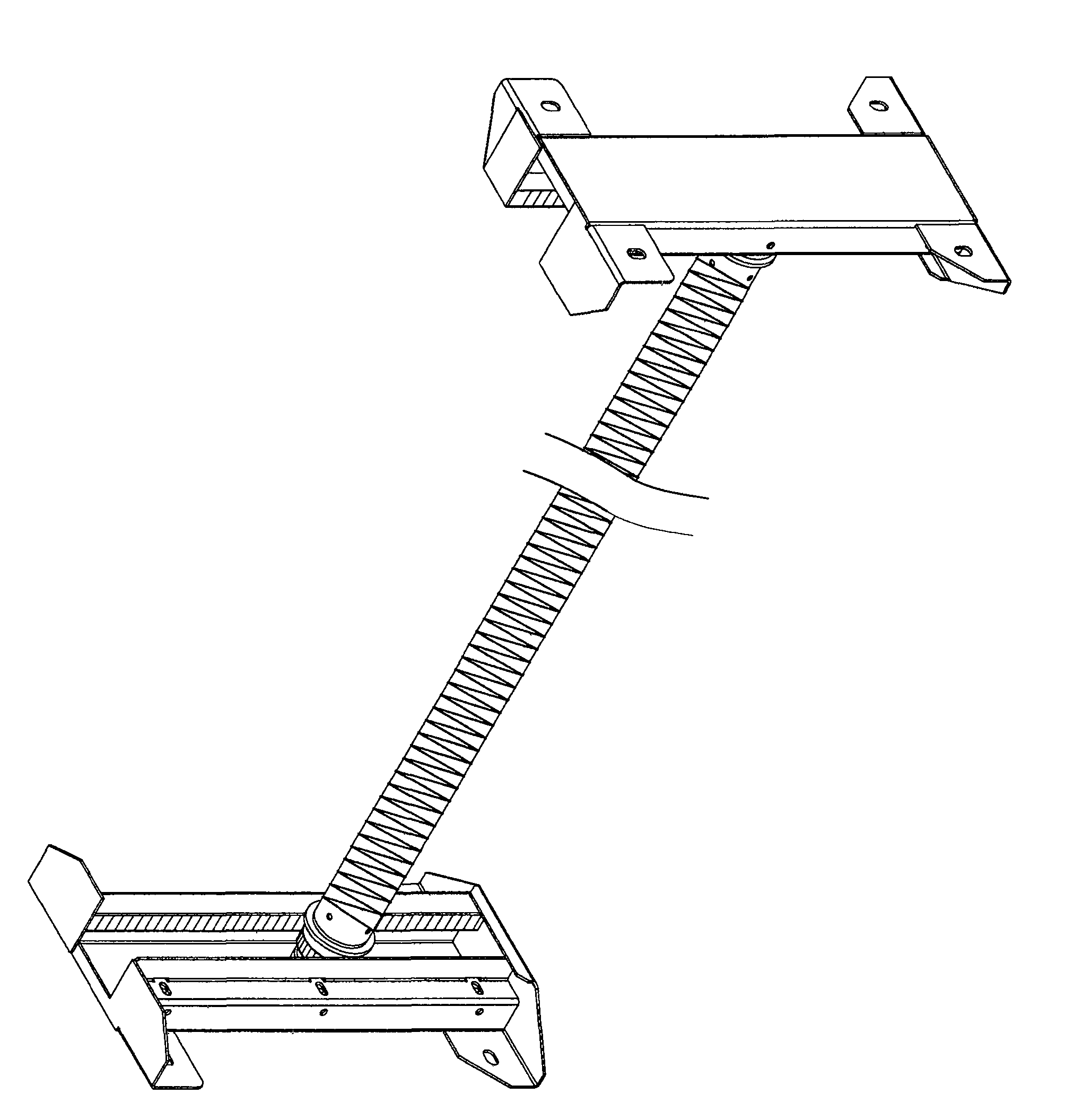

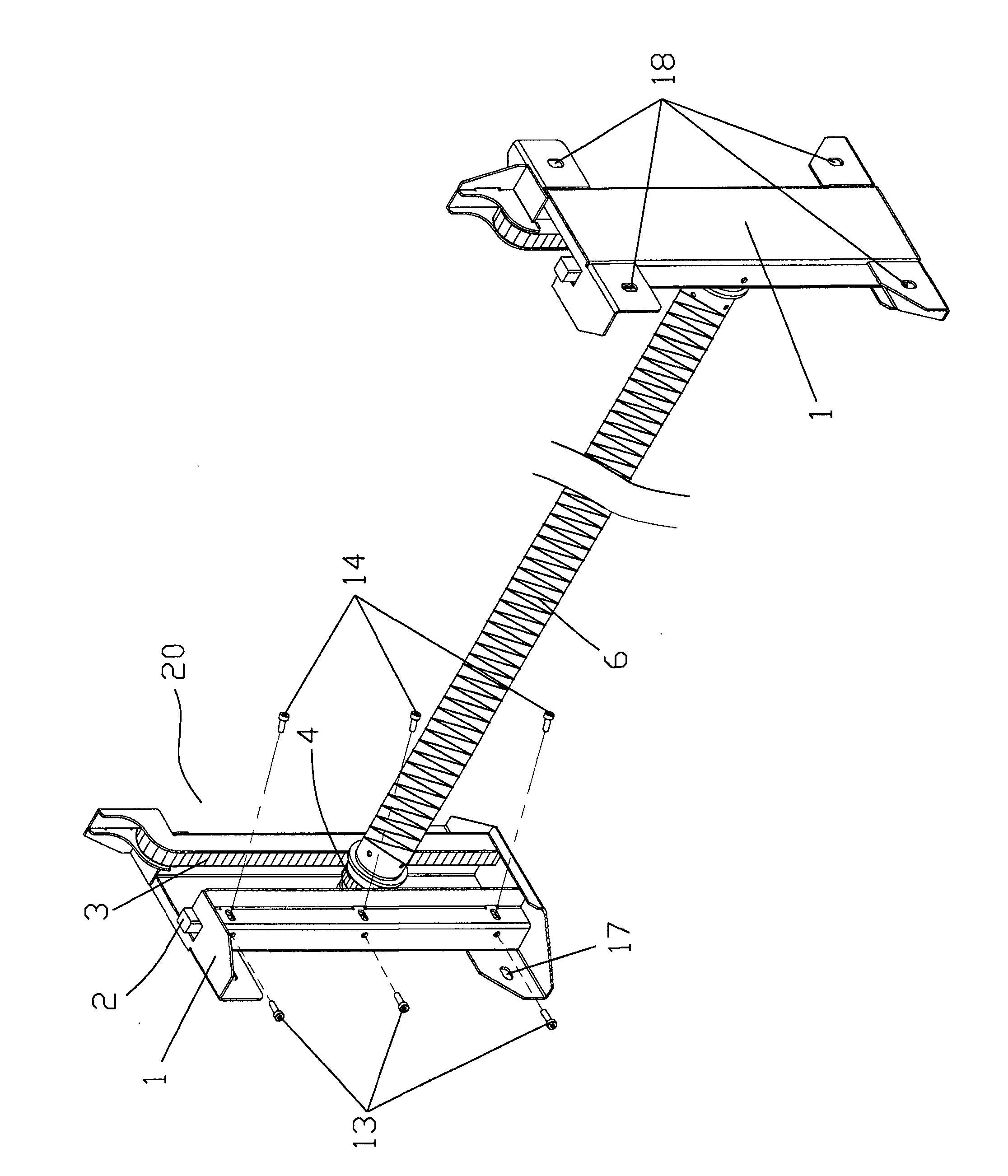

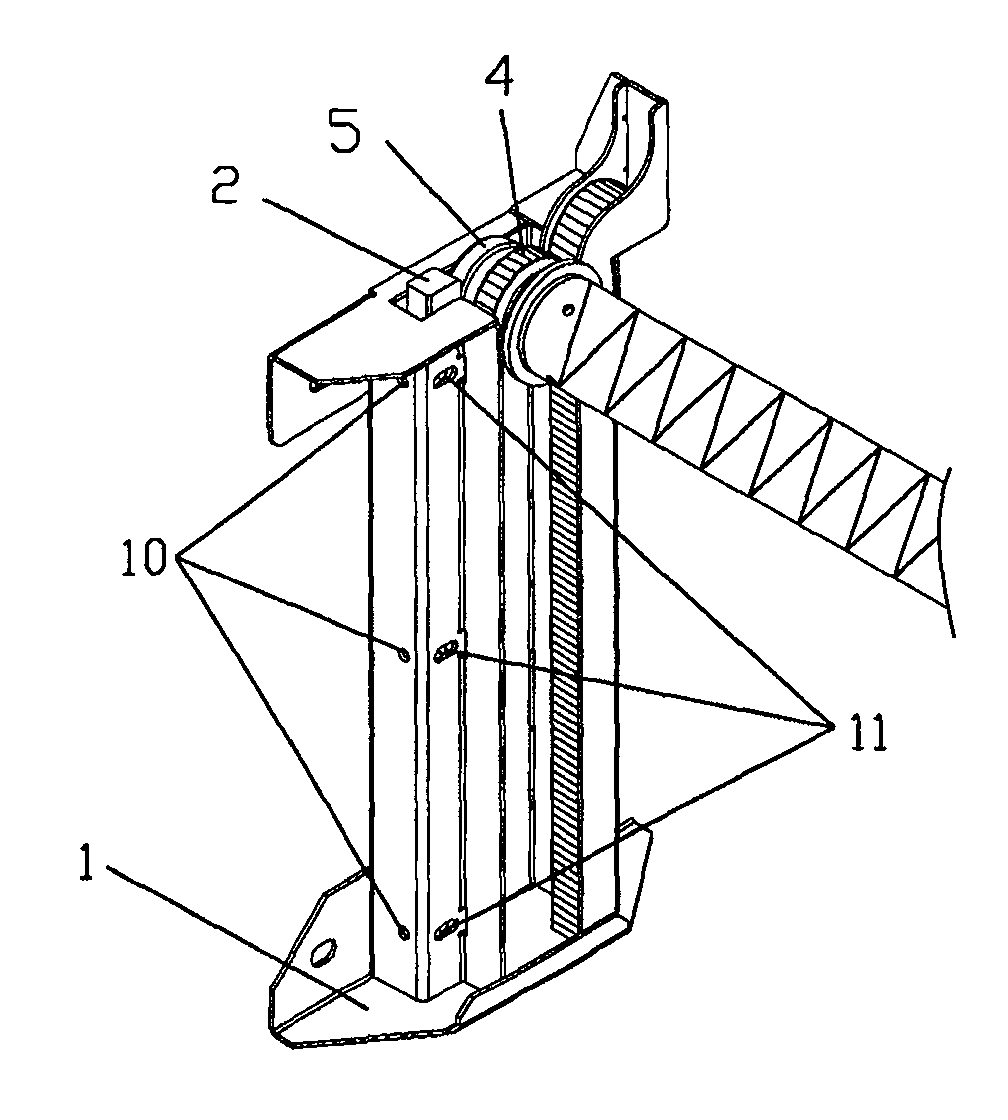

[0013] like Figure 2 to Figure 5 As shown, the printing medium tension mechanism unit for the printer of the present invention includes a pair of symmetrically arranged rack guides 20 and a tension bar 6 . Each rack guide 20 is composed of a bracket 1, a rack 3 arranged on it, and a gap adjustment backing plate 2. The gap adjustment backing plate 2 and the rack 3 are arranged alternately along the axial direction of the tension bar, wherein the gap adjustment backing plate 2 is inserted into the guide hole 9, and correspondingly, three screw holes 10 and three adjustment screws 13 are arranged on the bracket 1, and three long holes 11 and three fixing screws 14 are also arranged horizontally on the bracket 1. The two ends of the tension rod 6 are symmetrically fixedly provided with a gear 4 and a guide bearing 5, and the guide bearing 5 and the gear 4 are separated by a spacer ring 7, and the guide bearing 5 is fixedly installed on the tension rod 6 by a retaining ring 8.

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com