High precision dynamic gas rotation device for fluting machine

A transmission device and corrugated machinery technology, applied in the direction of mechanical processing/deformation, electrical program control, sequence/logic controller program control, etc., can solve the problems of shortened mechanical life, energy loss, low practicability, etc., to achieve The effect of prolonging the service life of the machine, increasing the operating speed, and high positioning accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing.

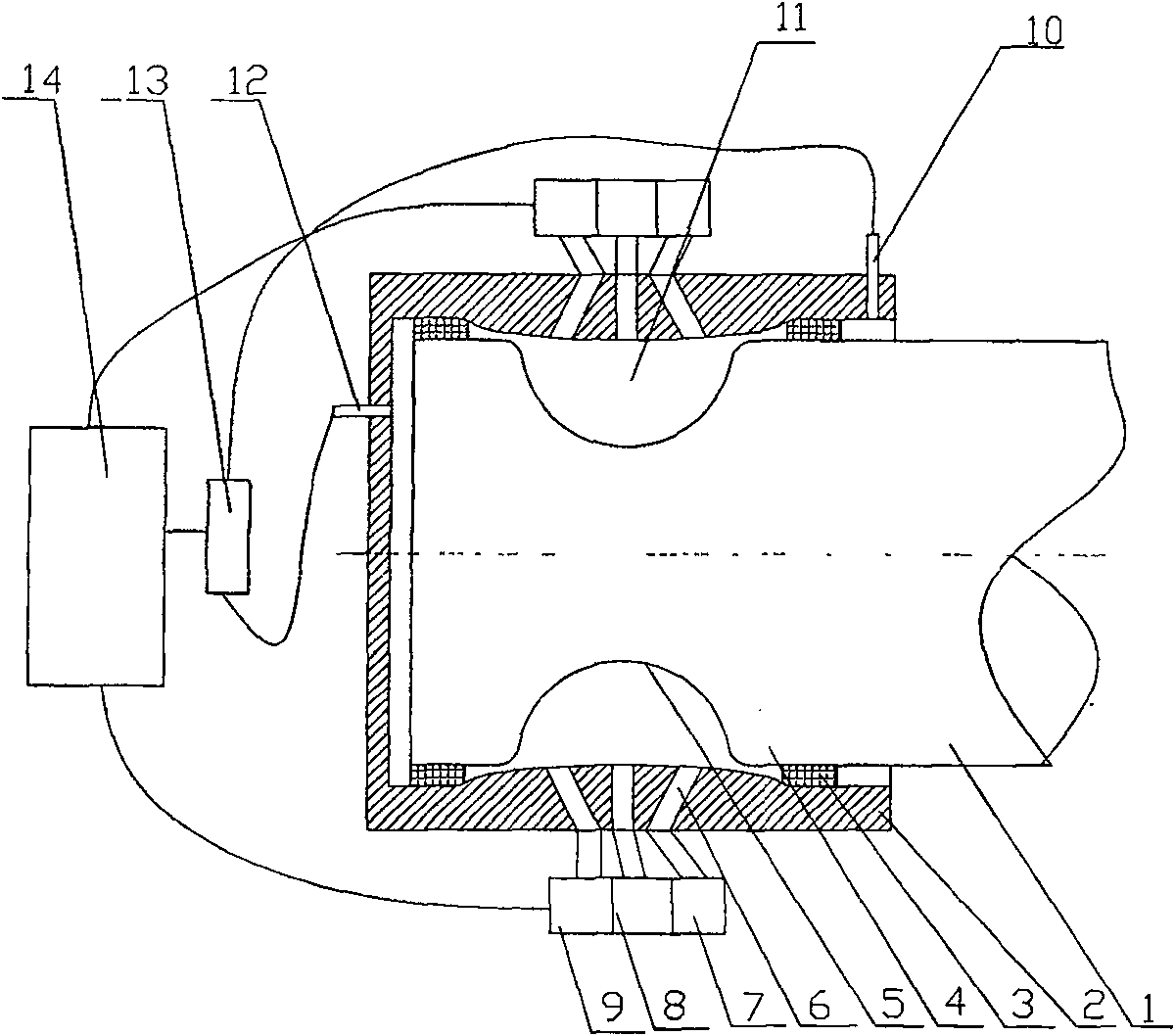

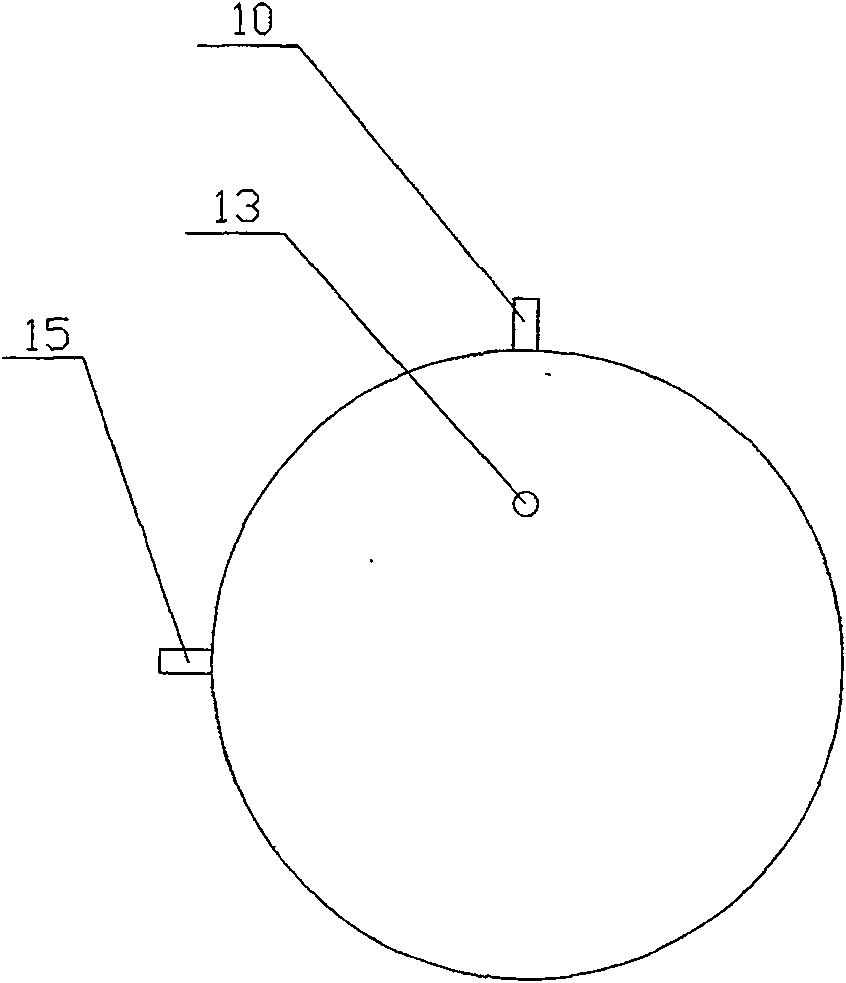

[0015] Referring to the accompanying drawings: the present embodiment includes a shaft 1 and a shaft sleeve 2, and the shaft sleeve 2 is provided with evenly distributed air holes 6, and the air holes 6 are divided into three rows, one of which is perpendicular to the axis of the shaft, and the other two The included angle between the inclined row holes and the radial direction of the shaft is 60°, and the corresponding gas flow control valves 7, 8, 9 are respectively installed on the three rows of vent holes, and rubber seals are installed on the shaft shoulder 4 of the shaft 1 ring 3, the gap between the shaft 1 and the shaft sleeve 2 is filled with the high-pressure gas 11 poured in from the vent hole 6; An axial displacement sensor 12 is installed, a radial displacement sensor 10 is installed in the vertical direction of the axle sleeve 2, a radial displacement sensor 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com