Square blank collecting bed using overturn cooling bed return power transmission

A technology of power transmission and cooling bed, applied in the fields of metallurgical machinery, machinery, and billet collection beds, can solve the problems of occupation, affecting labor efficiency, increasing unsafe factors, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

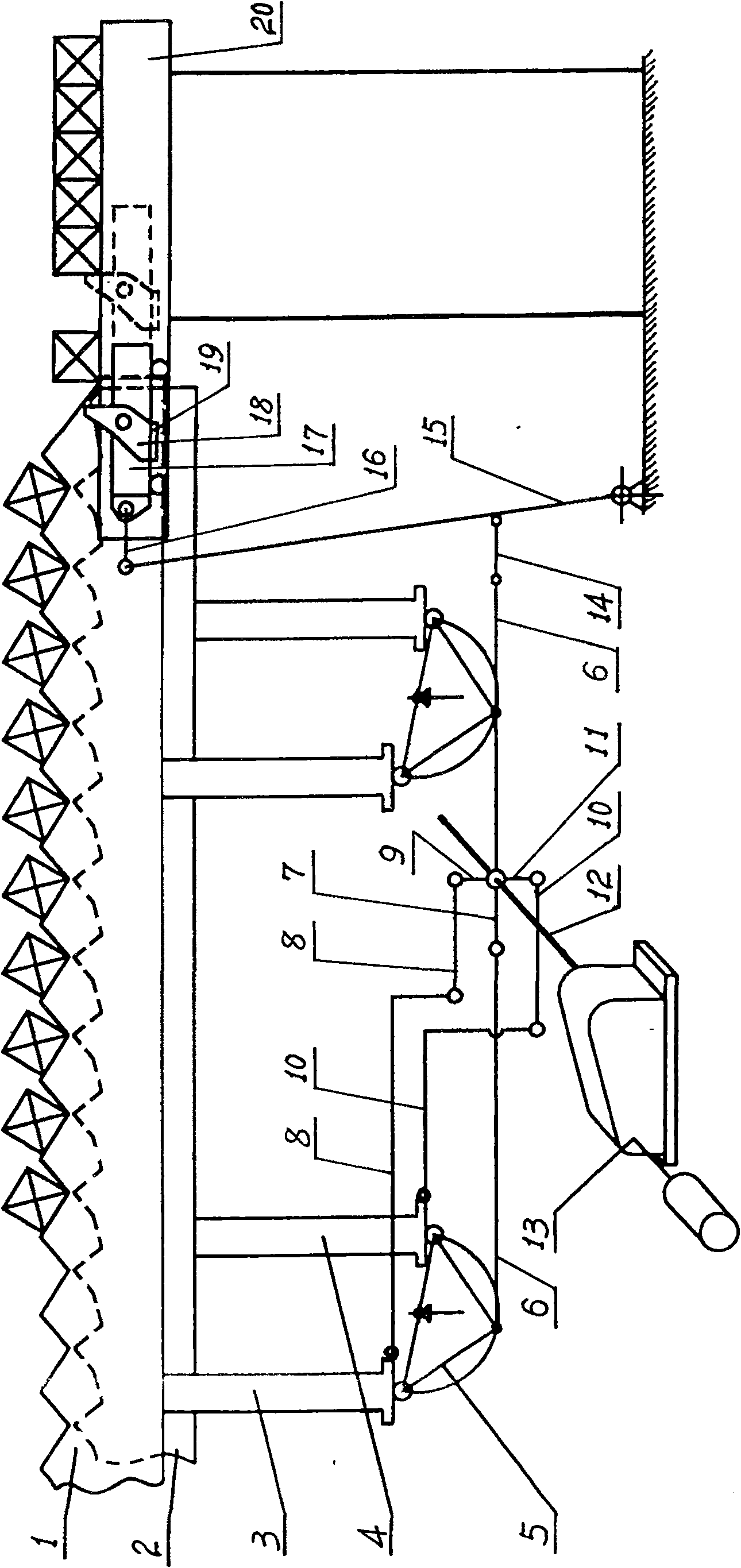

[0034] The present invention will be described in detail below in conjunction with the accompanying drawings. As shown in the accompanying drawings:

[0035] A billet collecting bed utilizing return power transmission of a turning cooling bed, including V-tooth 1, U-tooth 2, V-tooth beam 3, U-tooth beam 4, cradle 5, cradle pull rod 6, cradle eccentric sleeve 7, V Tooth tie rod 8, V-tooth eccentric sleeve 9, U-tooth pull rod 10, U-tooth eccentric sleeve 11, drive shaft 12, drive device 13,

[0036] Also be provided with lower connecting rod 14, billet pushing rocker 15, upper connecting rod 16, billet pushing car 17, billet pushing claw 18, backstop block 19, collecting bed 20;

[0037] The billet collecting bed utilizing the return power transmission of the turning cooling bed, the lower end surface of the V-tooth 1 and the upper end of the V-tooth beam 3 are fastened and connected by fasteners, and the lower end surface of the U-tooth 2 is connected to the U-tooth beam 4 Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com