Rotating and pressing operation type electronic component and electronic device using the same

An electronic component and pressing operation technology, which is applied in the direction of electrical components, digital computer parts, manual control mechanism, etc., can solve the problem of reduced operability, achieve improved productivity, simple structure, improved contact reliability and life expectancy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

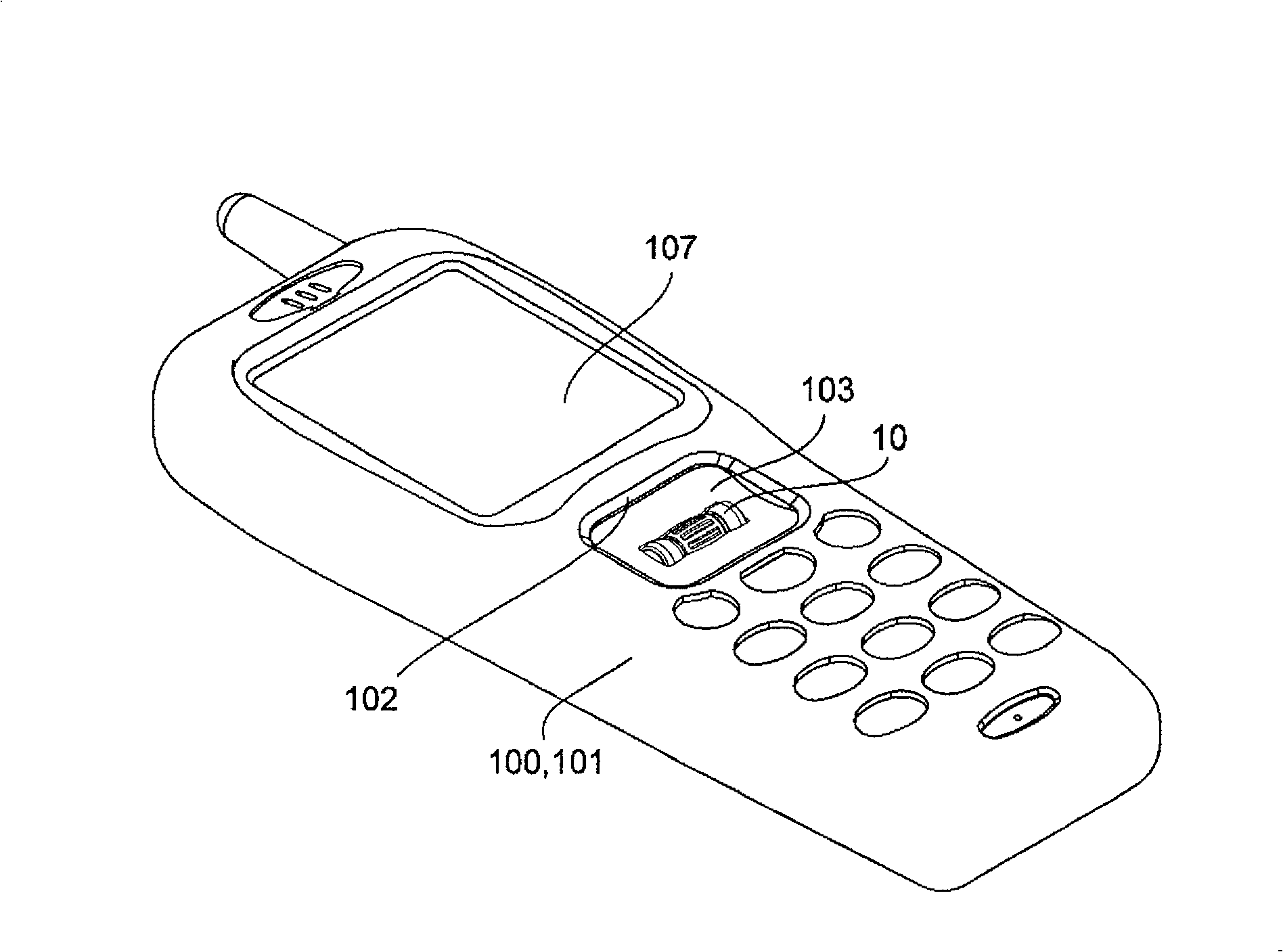

[0072] refer to figure 1 An embodiment according to the present invention will be described with reference to FIG. 27 .

[0073] Such as Figure 1 to Figure 1 As shown in 0, the first embodiment is applied to the rotation / press operation type electronic component 10 of the mobile phone 100 .

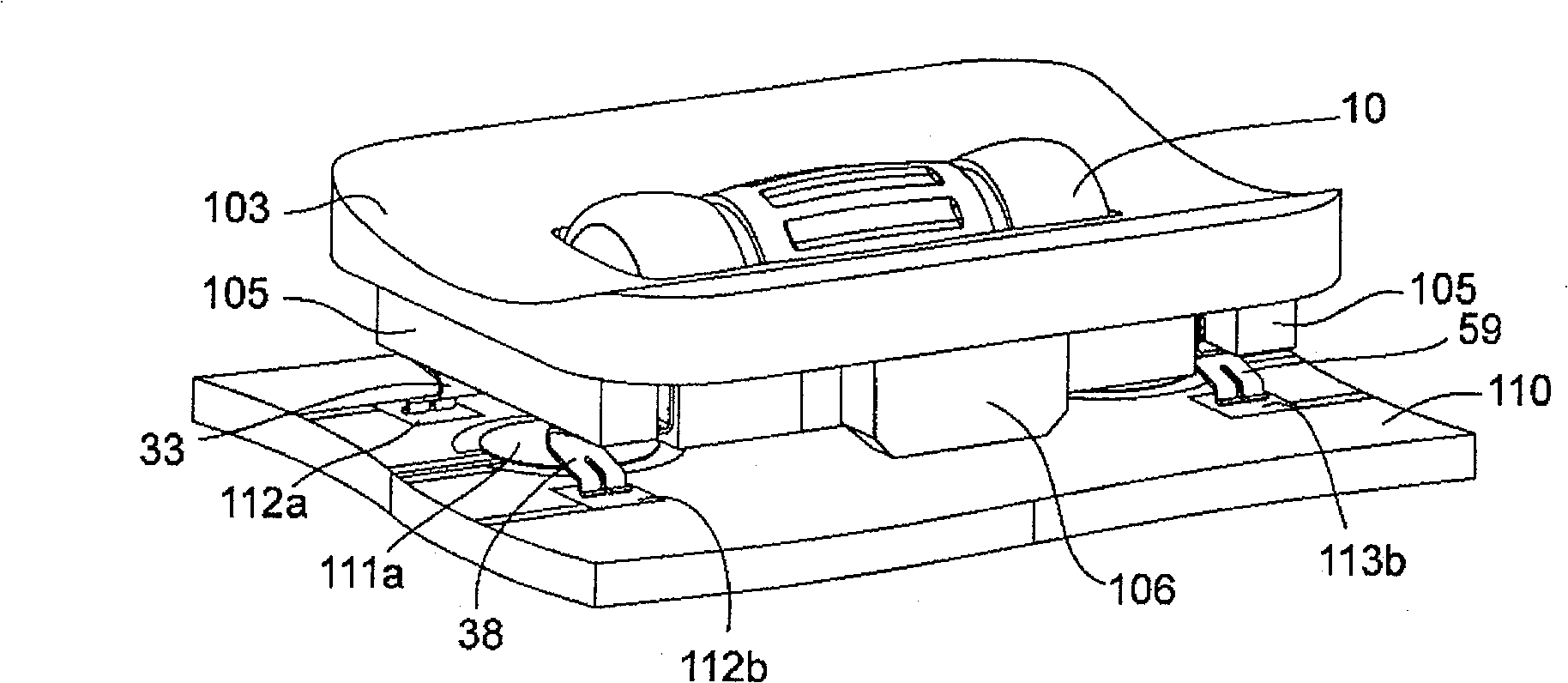

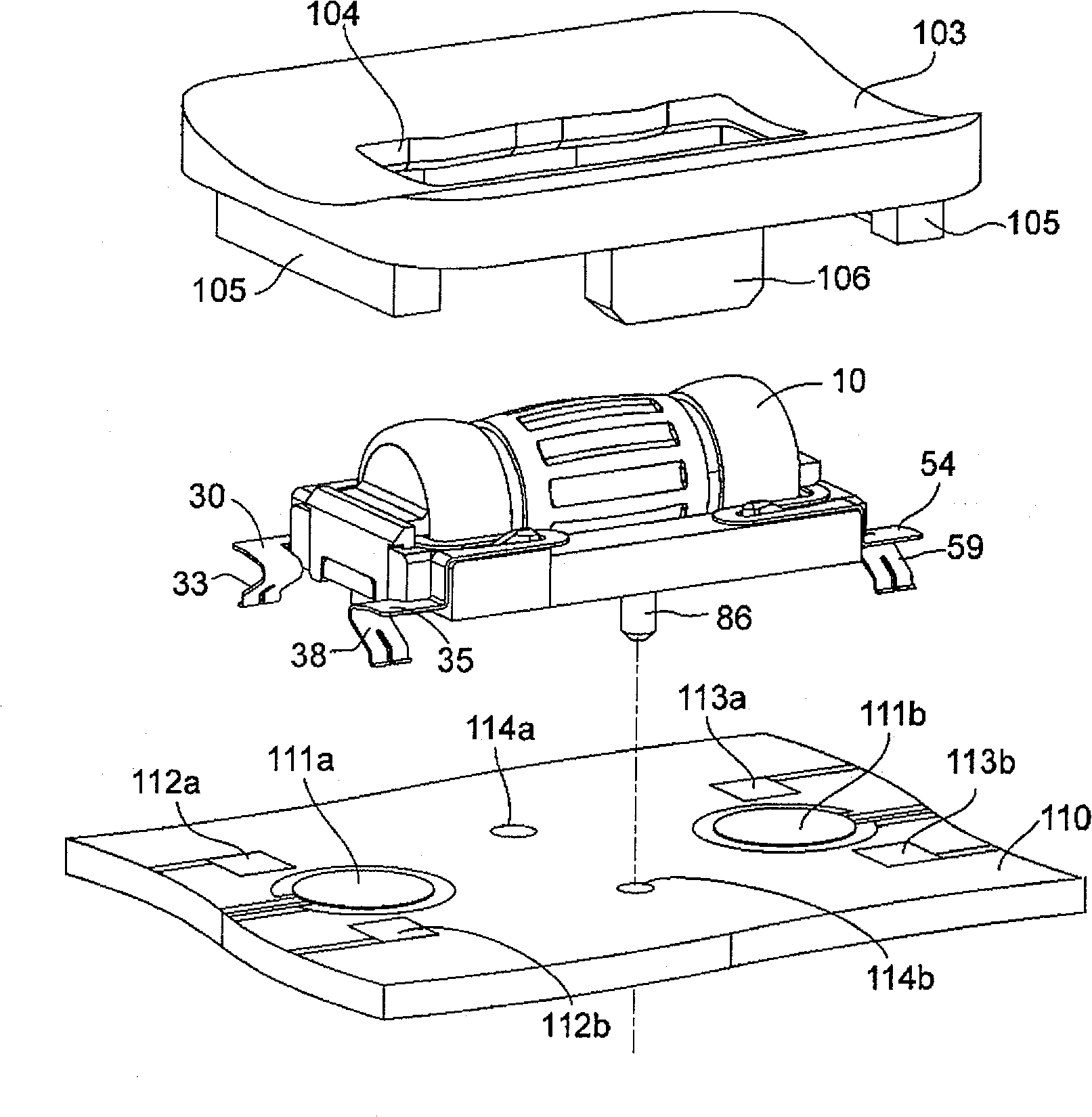

[0074] In the mobile phone 100, by fitting the cover 103 into the opening 102 of the case 101, the rotation and push operation type electronic component 10 is pressed and fixed on the surface of the printed circuit board 110 in the case 101. The cover 103 has a square opening 104 fitted with the rotary operation body 60 of the rotary and press-operated electronic component 10, and a pair of partition walls 105, 106 protrude from the lower edge of the opening 104. , thereby restricting the position of the above-mentioned rotation / press operation type electronic component 10 . In particular, by pressing down the terminal portions 33, 38 of the contact pieces 30, 35 and the terminal por...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com