Single-power bidirectional stir head for soft foundation and mixing pile machine having the same

A technology of weak foundation and mixing head, which is applied in the direction of sheet pile walls, foundation structure engineering, construction, etc., can solve the problems of difficult quality assurance, high cost, high cost, etc., and achieve the goal of ensuring the quality of the pile body, small size and long life Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Example 1 A set of 3-layer forward and reverse stirring heads

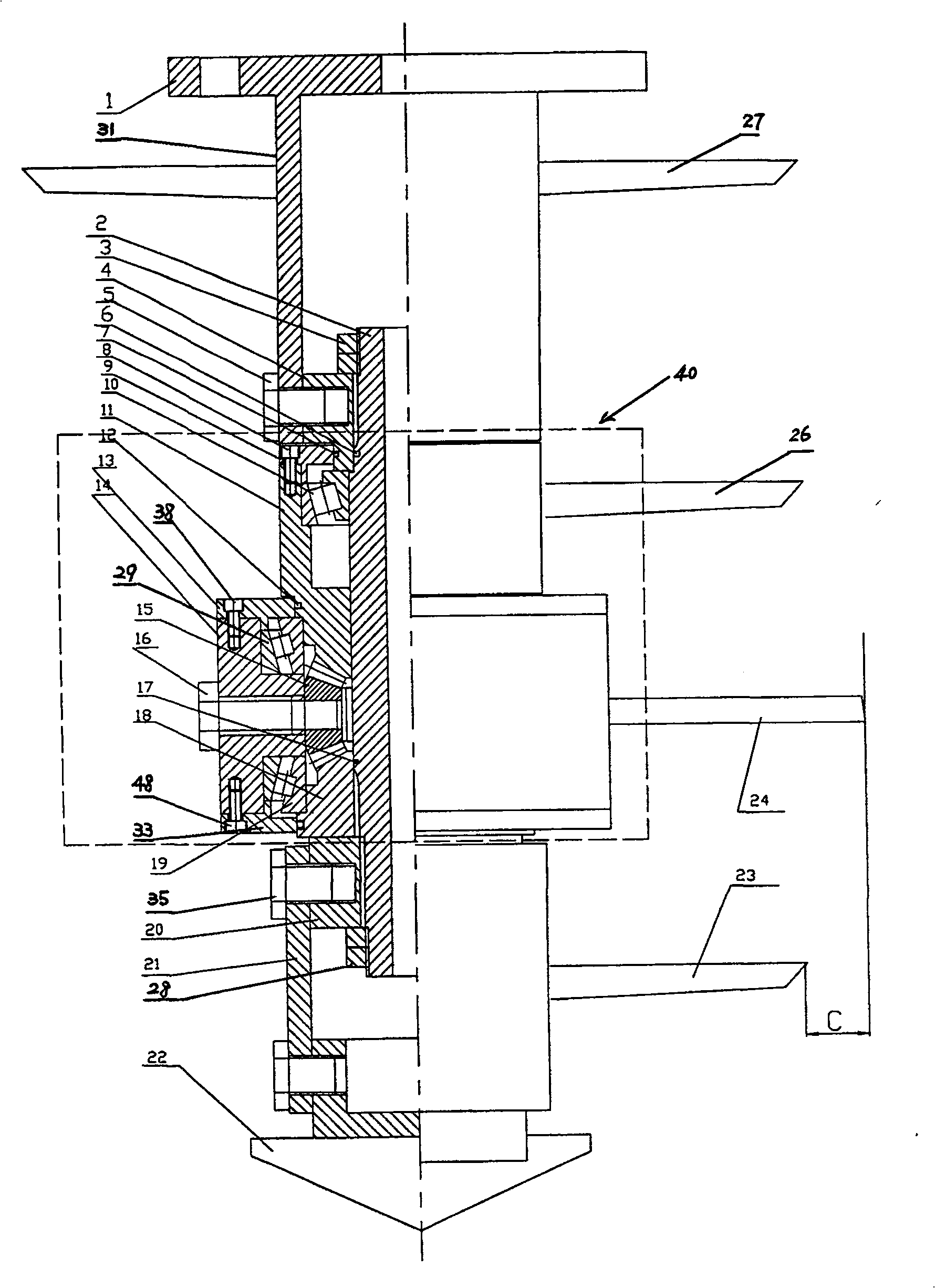

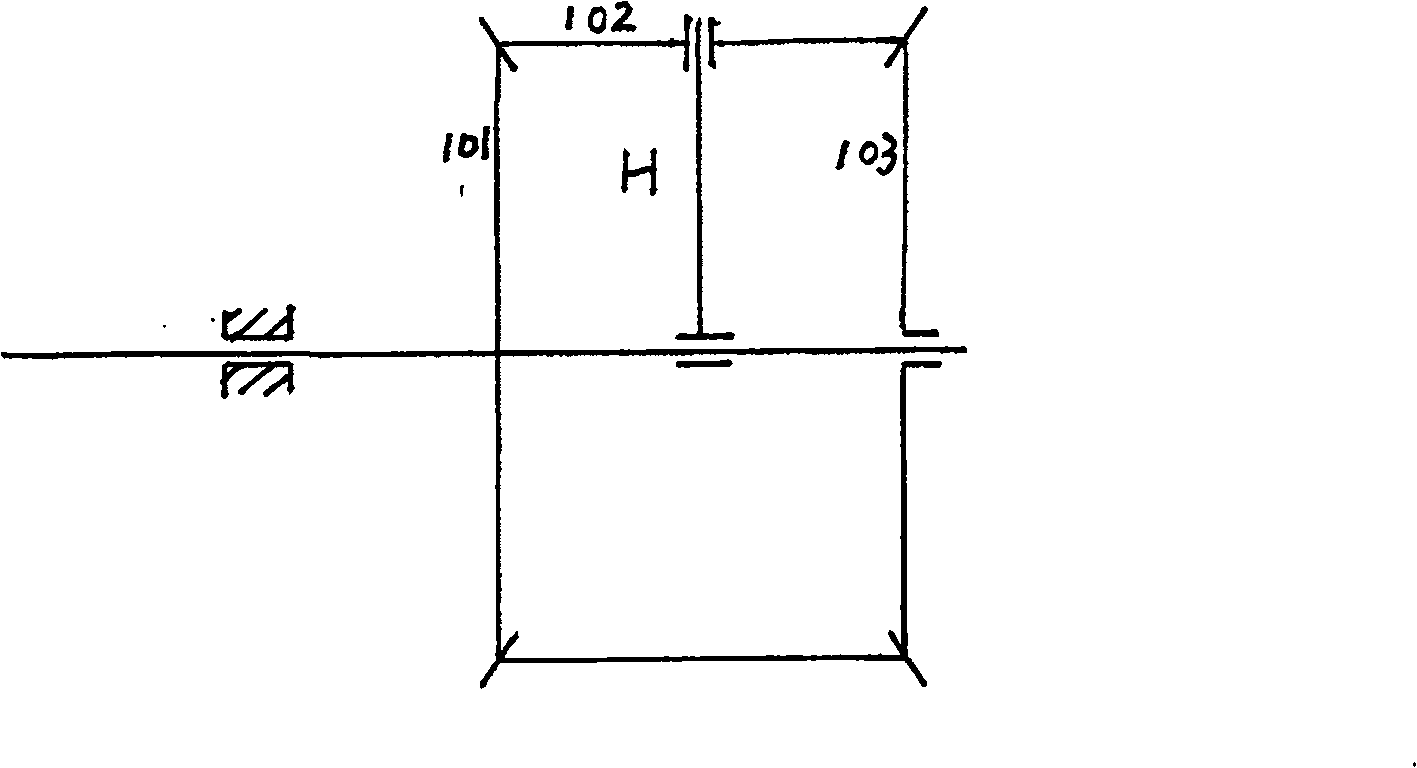

[0026] like figure 1 As shown, the single-power two-way multi-layer mixing head for weak foundations of the embodiment of the present invention includes a coupling disc 1 connected to the drill rod driven by the motor of the pile driver, an upper blade cover 31 located below the coupling disc 1 and a The front drill bit 22 also includes an epicyclic train mechanism 40 that changes the direction of rotation of the drill bit blades in different layers. The upper end of the transmission shaft of the epicyclic gear train mechanism 40 links to each other with the upper blade cover 31, and the lower end of the drive shaft links to each other with the lower blade cover 21; 31. A group of third-layer drill blade blades 27, first-layer drill blade blades 23 and second-layer drill blade blades 26 are respectively welded on the lower blade cover 21 and the driven gear 11 of the bevel gear epicyclic gear train mechanis...

Embodiment 2

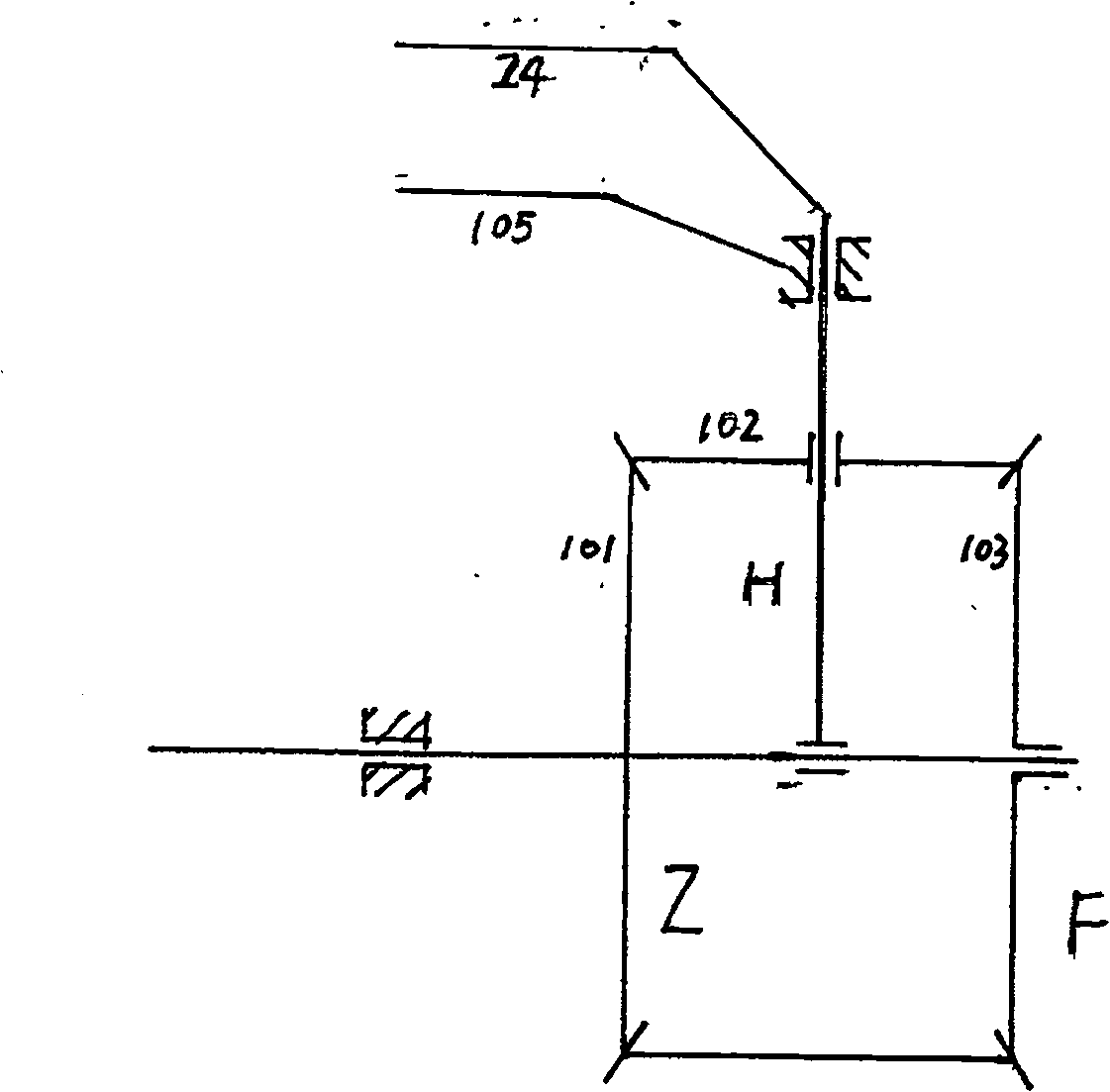

[0037] Example 2 Two sets of 4-layer forward and reverse stirring heads

[0038] like Figure 4 As shown, the difference between this embodiment and Embodiment 1 is that the two sets of bevel gear epicyclic gear trains 40 are connected with the connecting sleeve 25, and there are no drill blades welded on the upper blade sleeve 31, and there are 4 blades from bottom to top. The blade of the drill bit achieves the combined purpose of positive and negative rotation. Specific implementation and figure 1 Same, no more details.

[0039] Certainly, the combination of multiple bevel gear epicyclic gear trains 40 can be used to achieve multiple positive and negative combinations.

[0040]The above-mentioned embodiments take the bevel-toothed epicyclic gear train mechanism as an example, of course, a straight-toothed epicyclic gear train mechanism can also be used.

[0041] The single-power two-way multi-layer mixing head of the present invention is installed on the existing agitat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com