Connection element for the captive mounting of a lever-like cam follower

A technology for connecting components and retaining rods, which is applied in the direction of engine components, machines/engines, valve devices, etc., and can solve problems such as narrow contact surfaces of cams

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

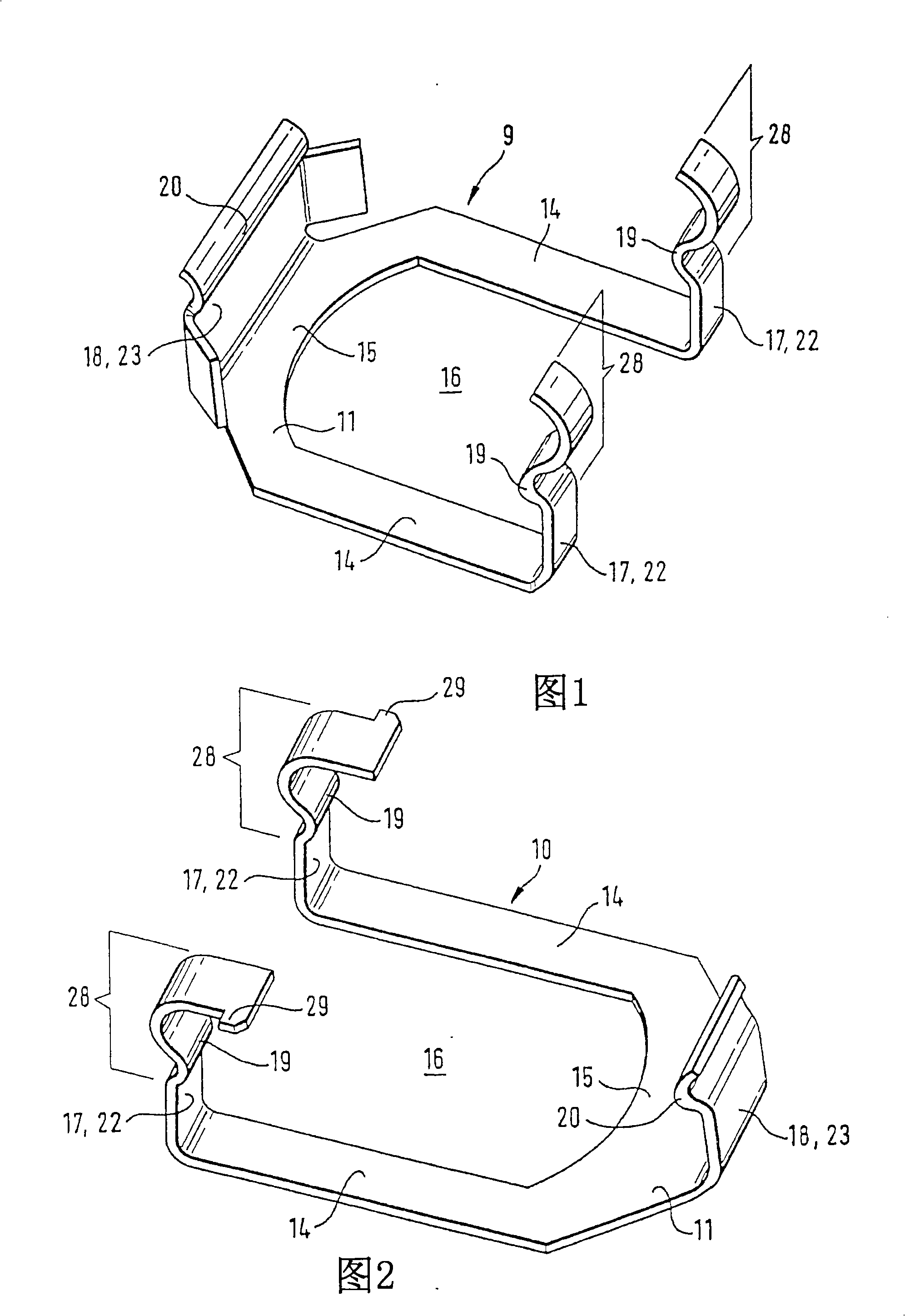

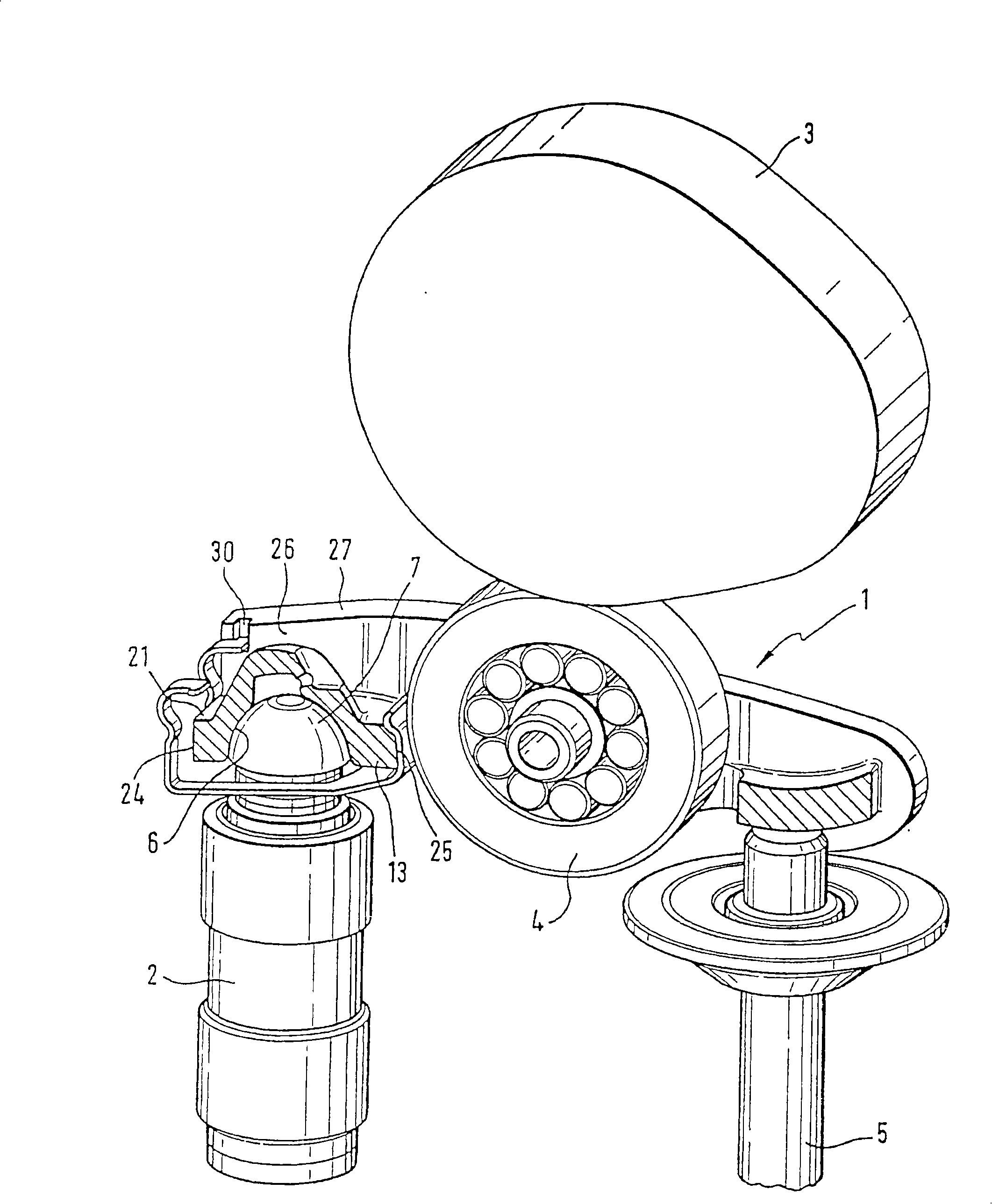

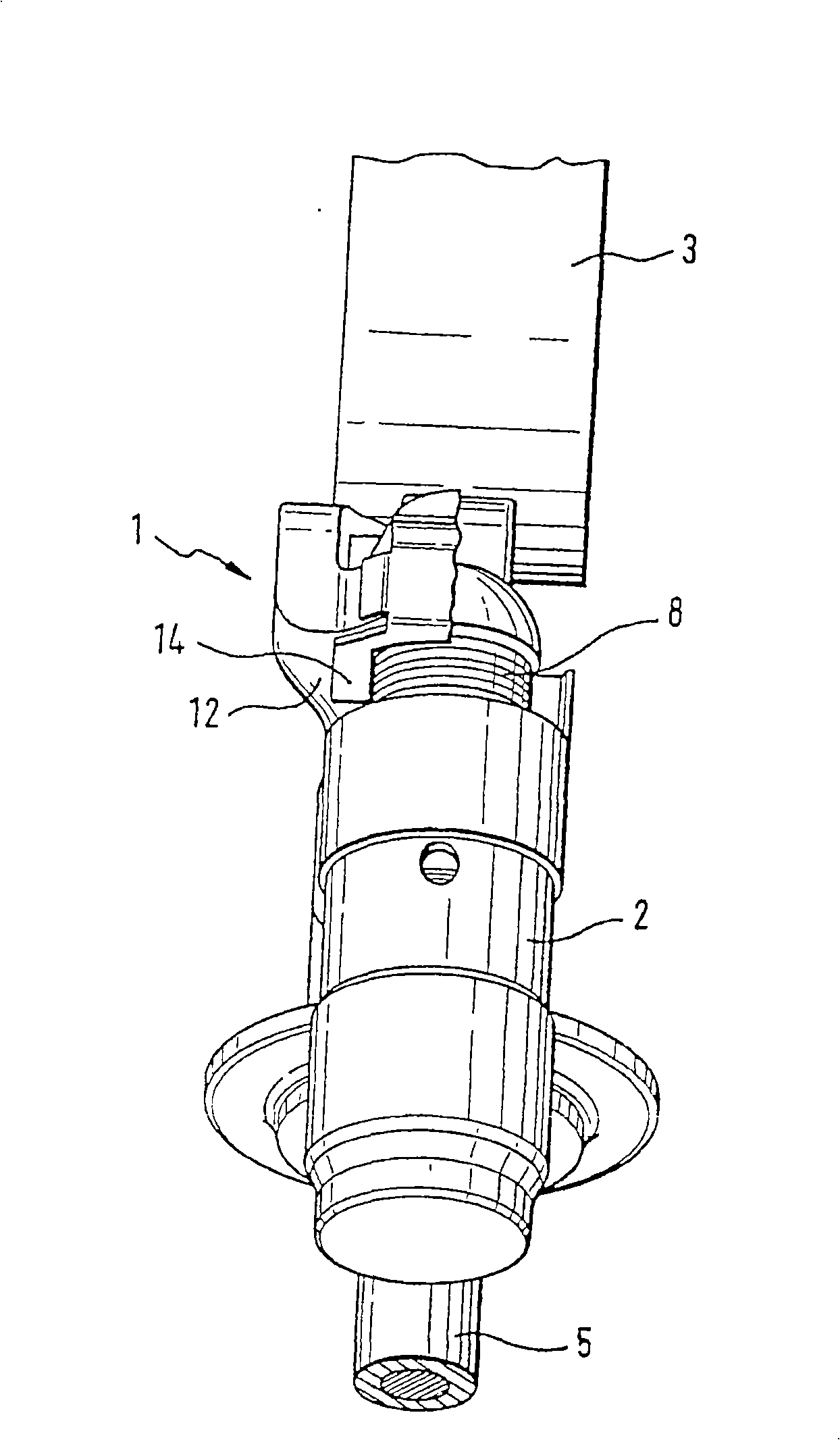

[0021] image 3 and Figure 4 Shown is a cam follower 1 and a support element 2 , on which it is rotatably mounted, which is designed with play compensation here with a hydraulic valve not shown in detail. In a known manner, the cam follower 1 is driven by the cam 3 in the actuation direction of the gas exchange valve 5 by means of a rotatably mounted roller 4 connected to the cam follower 1 . It is obviously also possible to provide a smooth surface rigidly connected to the cam follower 1 as a cam contact instead of the roller 4 . The cam follower 1 is, in the exemplary embodiment shown, a rocker pin, has a U-shaped cross-section and is preferably produced in a forming method from a sheet material.

[0022]As can also be seen from the described figures, the cam follower 1 has a spherical shape 6 , by means of which it is attached to the spherical end 7 of the support element 2 . Underneath the spherical end 7 there is an annular groove 8, as in the figure 1 or figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com