Automatic testing method and apparatus for performance of breathing relief valve

An automatic testing device and automatic testing technology, which is applied in fluid tightness testing, measuring devices, testing of machine/structural components, etc., can solve problems such as inability to realize automatic control, large influence of human factors, large detection errors, etc., and achieve Analyze and improve the effect of safety valve performance, strong anti-interference ability and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

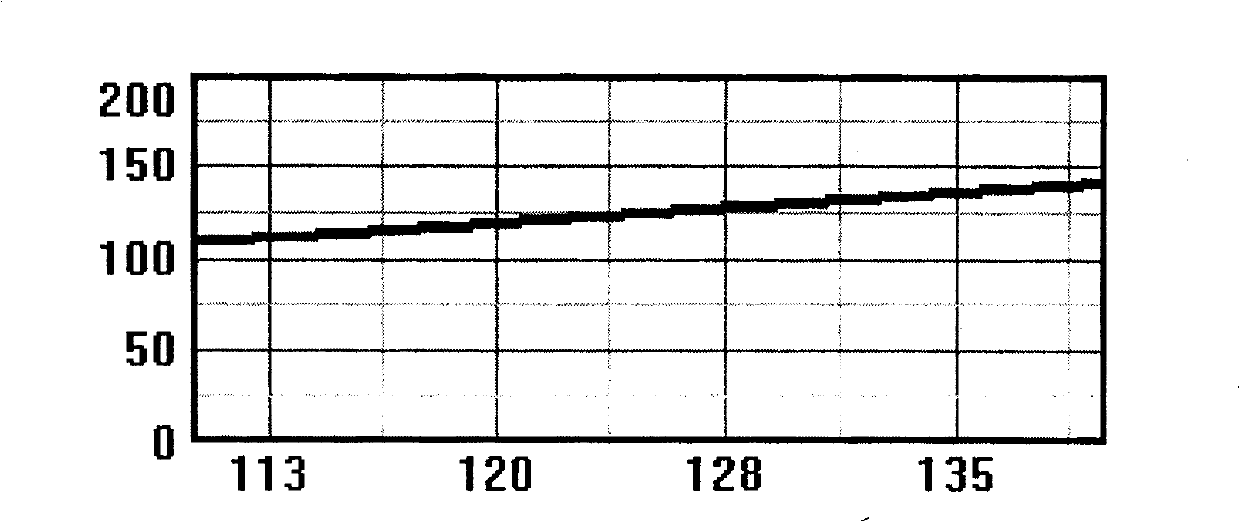

[0049] The invention can simulate the actual application situation. According to the pressure change in the tank body of the tanker, the valve plate of the safety valve will move. The invention judges whether the performance of the safety valve meets the design requirements by detecting the opening pressure value of the valve plate of the safety valve.

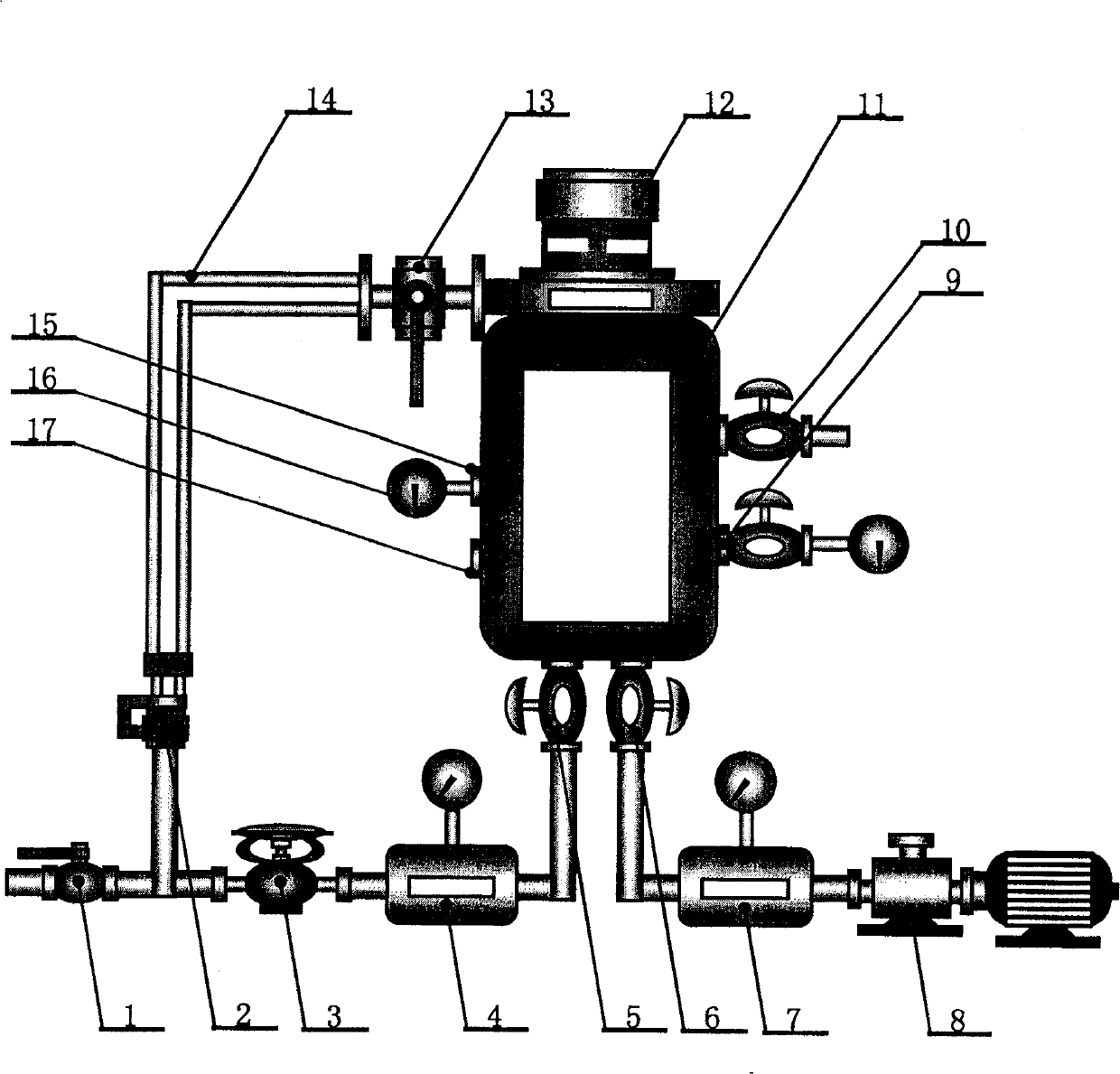

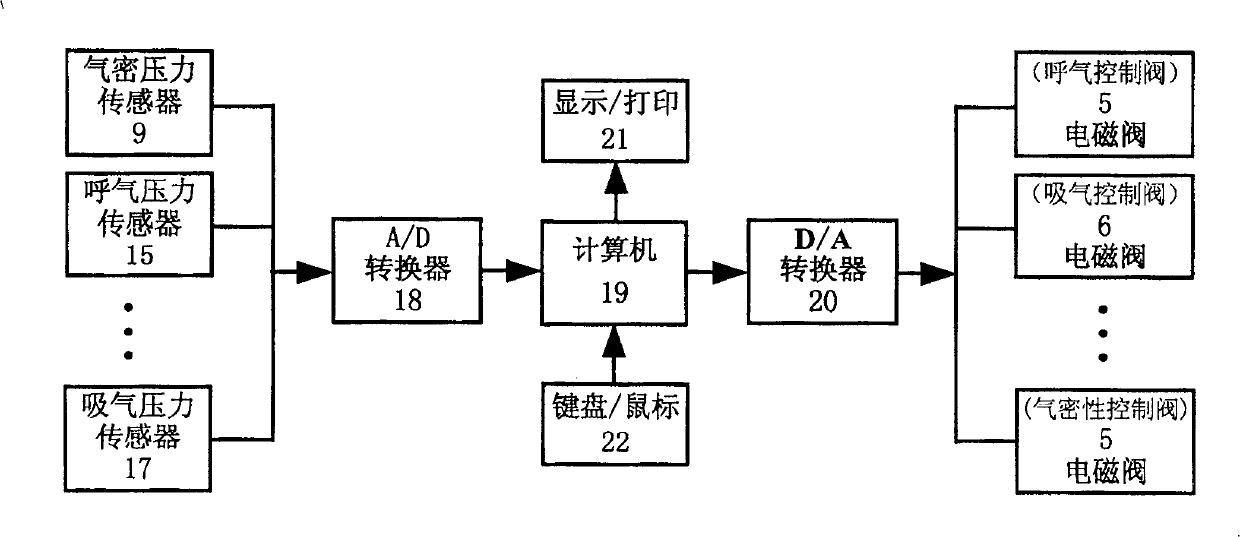

[0050] see figure 1 , 2 , the implementation steps of the breathing safety valve performance automatic testing method of the present invention include:

[0051] (1) The first is identity verification. Identity verification is to input the user information including user name and user password into the computer control device, and verify and confirm the user authority through the computer control device.

[0052] (2) Connect the interface of the breathing safety valve to be tested with the interface of the test gas circuit system.

[0053] (3.1) Determine the test category: the test category includes breath test, inhalation ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com