Method for directional tank shallow planting for Chinese yam

A cultivation method and directional trough technology, which is applied in the shallow cultivation field of yam directional trough, can solve the problems of easily damaged tubers, poor commodity properties, labor and time-consuming, etc., and achieve the effects of good commodity properties, convenient harvesting, and fast growth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

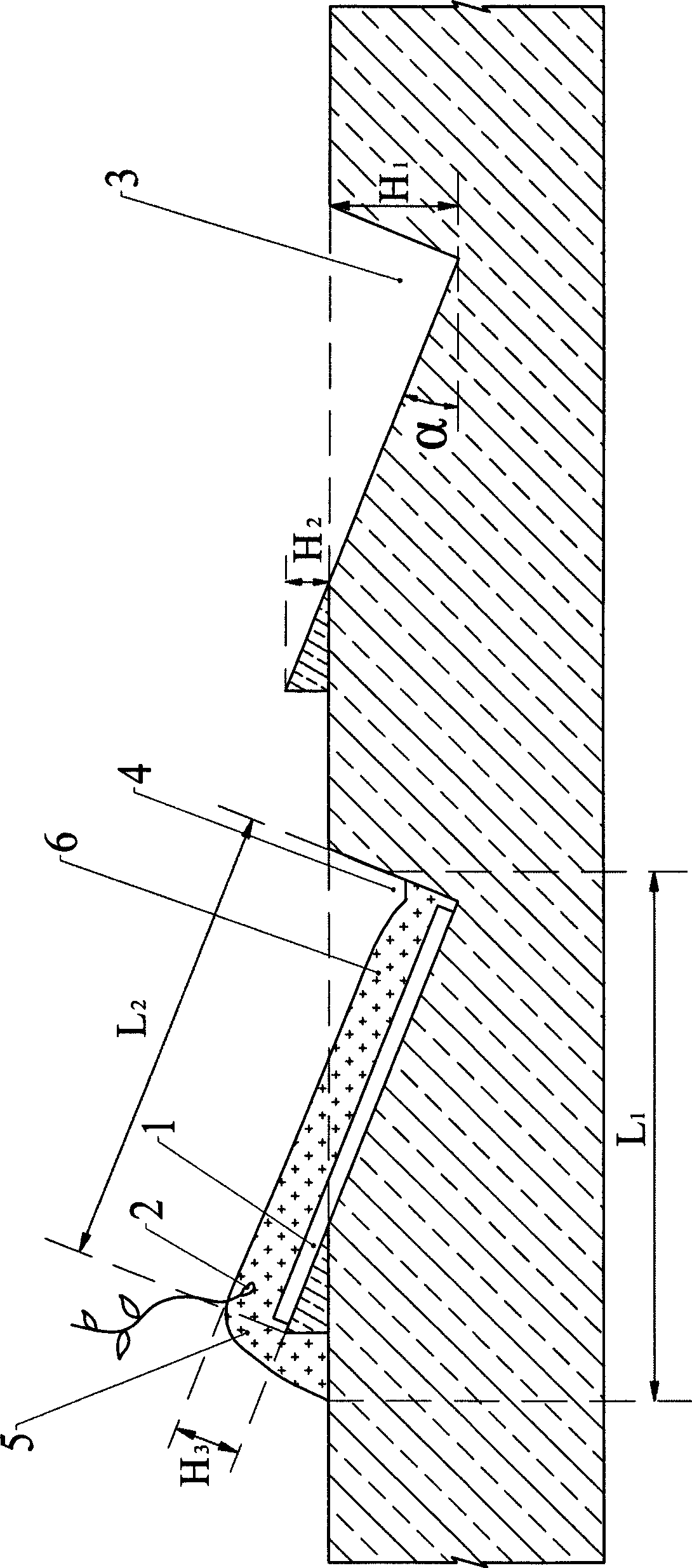

[0020] refer to figure 1 , the concrete steps of a kind of yam directional groove superficial cultivation method are:

[0021] 1), choose potato seeds: choose the thick and healthy potato pieces harvested in Xinyuan as potato seeds;

[0022] 2) Prepare the plastic directional groove: according to the length and size of the tubers of different varieties of yam, customize the plastic with a groove length of 50-110cm, groove depth of 1.8-4.5cm, groove arc length of 7-14cm, and groove arc curvature radius of 1.5-5cm. Orientation groove 1, the upper end of the groove is closed, the lower end of the groove is also closed, and three small holes with a diameter of 2 to 3 mm are arranged at the bottom of the groove;

[0023] 3) Site preparation and trough placement: build roads and drainage and irrigation systems in the garden, use 25kg of lime per mu, evenly sprinkle lime powder, and set the distance between rows of ridges and ditches to be L 1 =0.9~1.7m excavation slope 3, slope wi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com