Safety burning method for arsenic-enriched plant ciliate desert-grass

A technology for enriching plants and centipede grass, applied in the field of environmental engineering, can solve problems such as arsenic volatilization, secondary environmental pollution, etc., and achieve the effects of small engineering volume, pollution avoidance, and high management technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] Taking the arsenic hyperaccumulator plant Centipede Grass as an example, first dry and pulverize Centipede Grass (with a particle size of 2 mm), weigh 0.2 g of the sample and put it into a crucible. The pure centipede grass sample was directly put into the muffle furnace for ashing treatment; a part of the centipede grass sample was first added with 15% Mg(NO 3 ) 2 The solution is wet, heated at 80°C, and after drying, spread 0.2g of MgO dry powder (with a particle size of 0.15-0.2mm) evenly on the surface of the sample; add 0.2g of CaO powder to some centipede grass samples and mix well. Incineration treatment is carried out at 300, 400, 500, 600, 700 and 800°C.

[0023] The volatilization loss rate of arsenic in samples under different treatment conditions varies with the incineration temperature see figure 2 . The results showed that when the incineration temperature was 100-200 °C, the loss rate of arsenic in the pure centipede grass sample was very low (<1%); ...

Embodiment 2

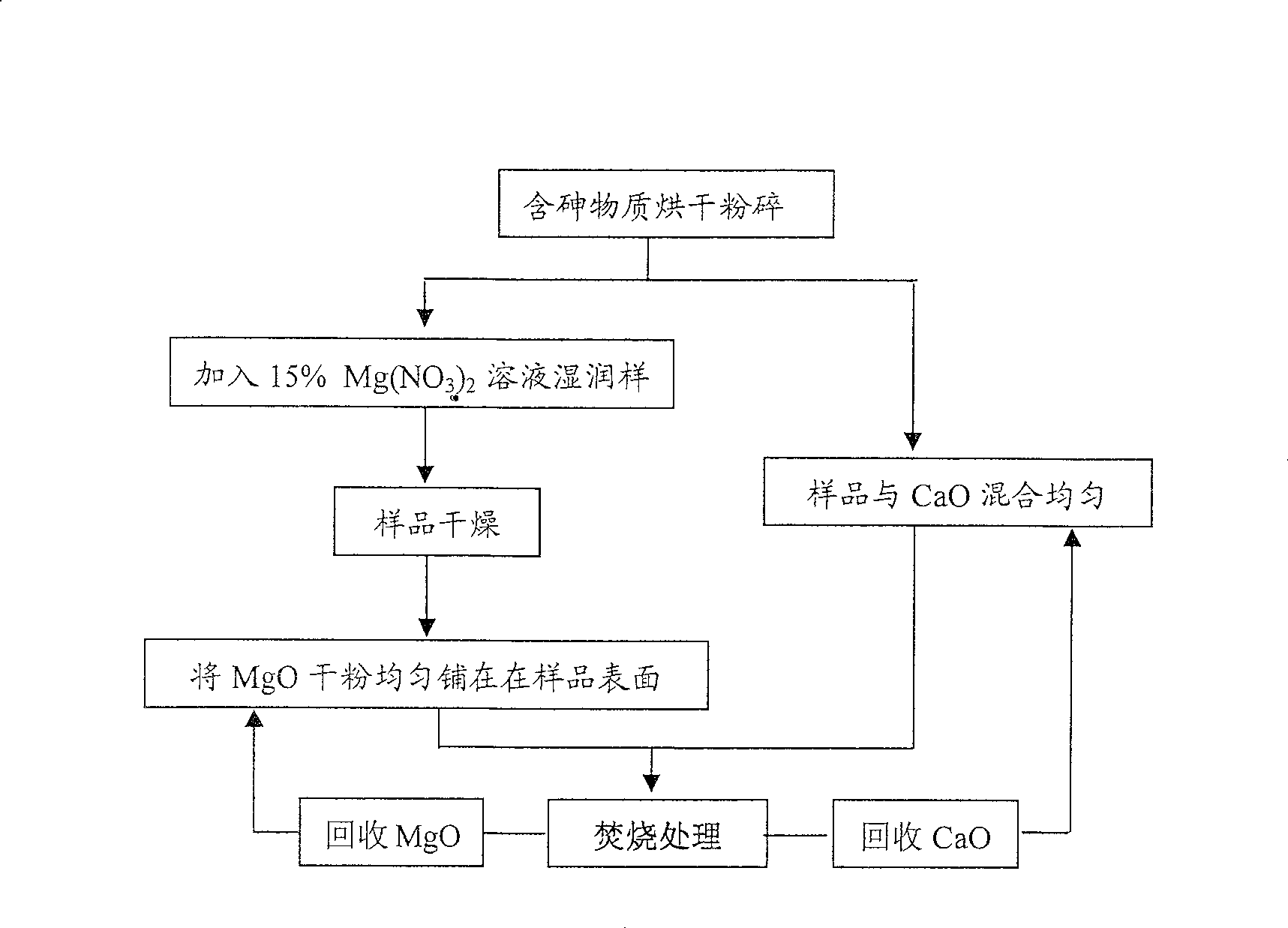

[0026] according to figure 1 The schematic diagram of the safe incineration process of adding arsenic-fixing agents to arsenic-containing substances is shown. Taking the arsenic hyperaccumulator plant Centipede Grass as an example, compare the effects of different dosages of two arsenic-fixing agents on the samples at an incineration temperature of 800°C. Arsenic fixation effect. The weighing amount of centipede grass in all treatments is 0.4g. image 3 The CK treatment in the above indicates that the pure centipede grass sample is directly burned at high temperature, and the results show that more than 22% of the arsenic will volatilize into the environment; the 4 treatments that add arsenic-fixing agent can effectively control the volatilization of arsenic (As loss rate is less than 3% ): Mg (add MgO 0.2g, 15% Mg(NO 3 ) 2 solution 5ml), Mg (add MgO 0.1g, 15% Mg (NO 3 ) 2 solution 2.5ml), Ca (add CaO 0.2g) and Ca (add CaO 0.1g). Therefore, considering the economic effec...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com