Complete vehicle inspection pass correlation system and method thereof

A qualification, inspection line technology, applied in the direction of motor vehicles, vehicle testing, registration/indication of vehicle operation, etc., can solve problems such as forgetting labels or reading labels incorrectly

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

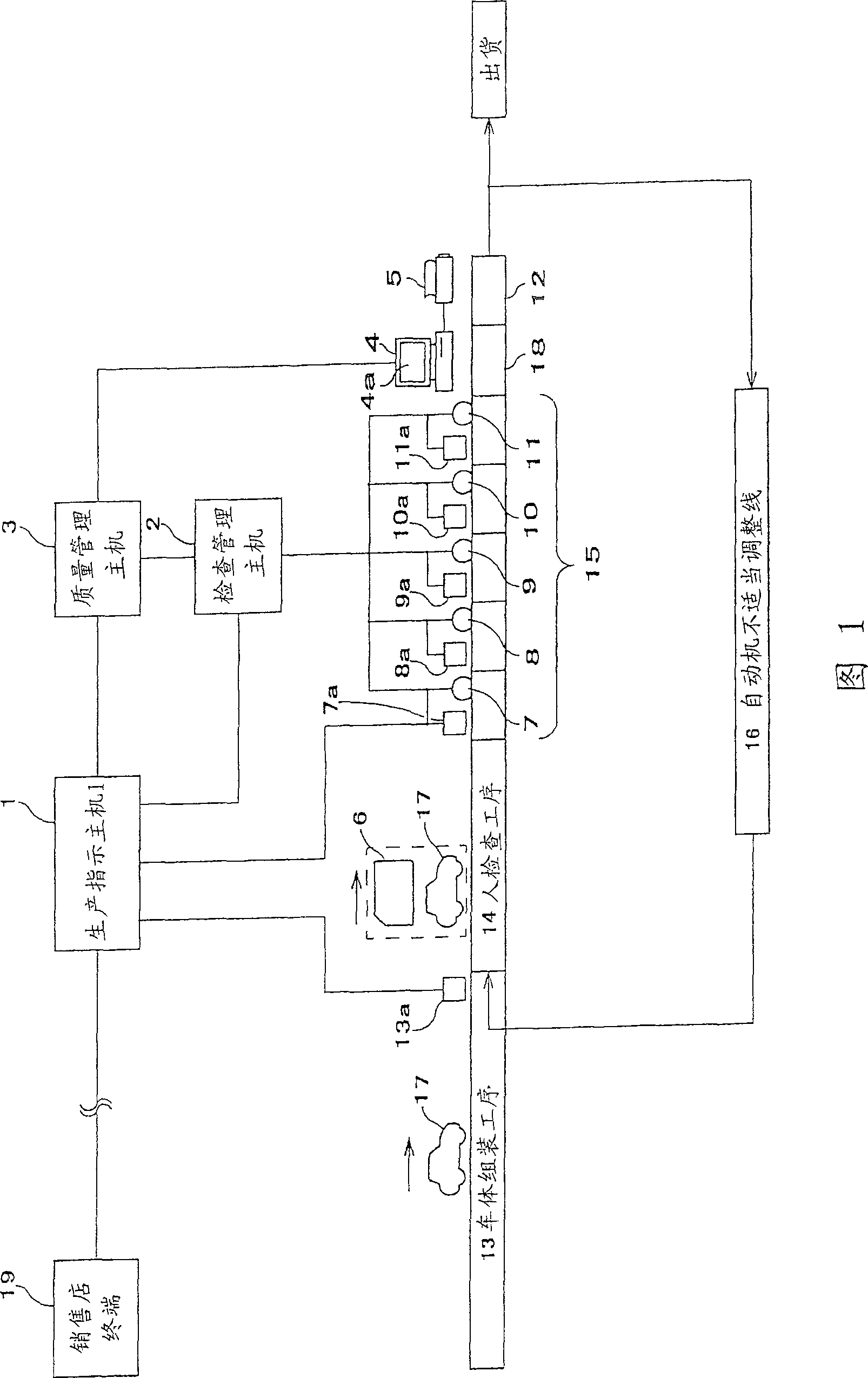

[0026] Embodiments to which the present invention is applied will be described with reference to the drawings.

[0027] (Complete the composition of the car inspection line)

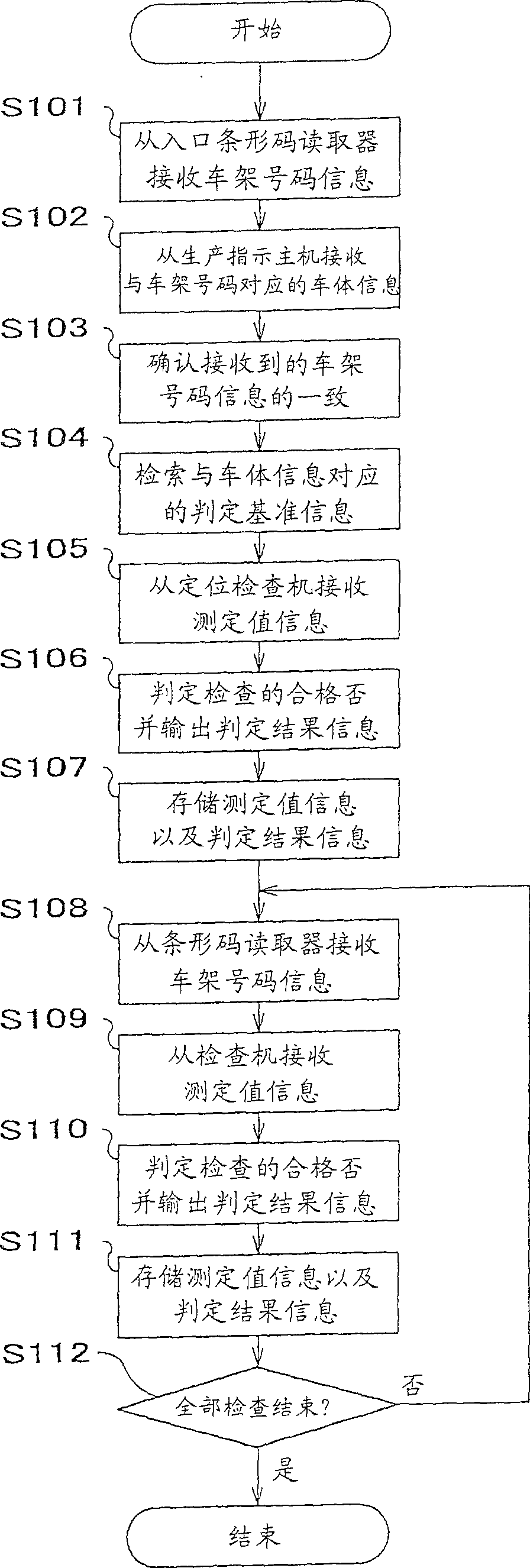

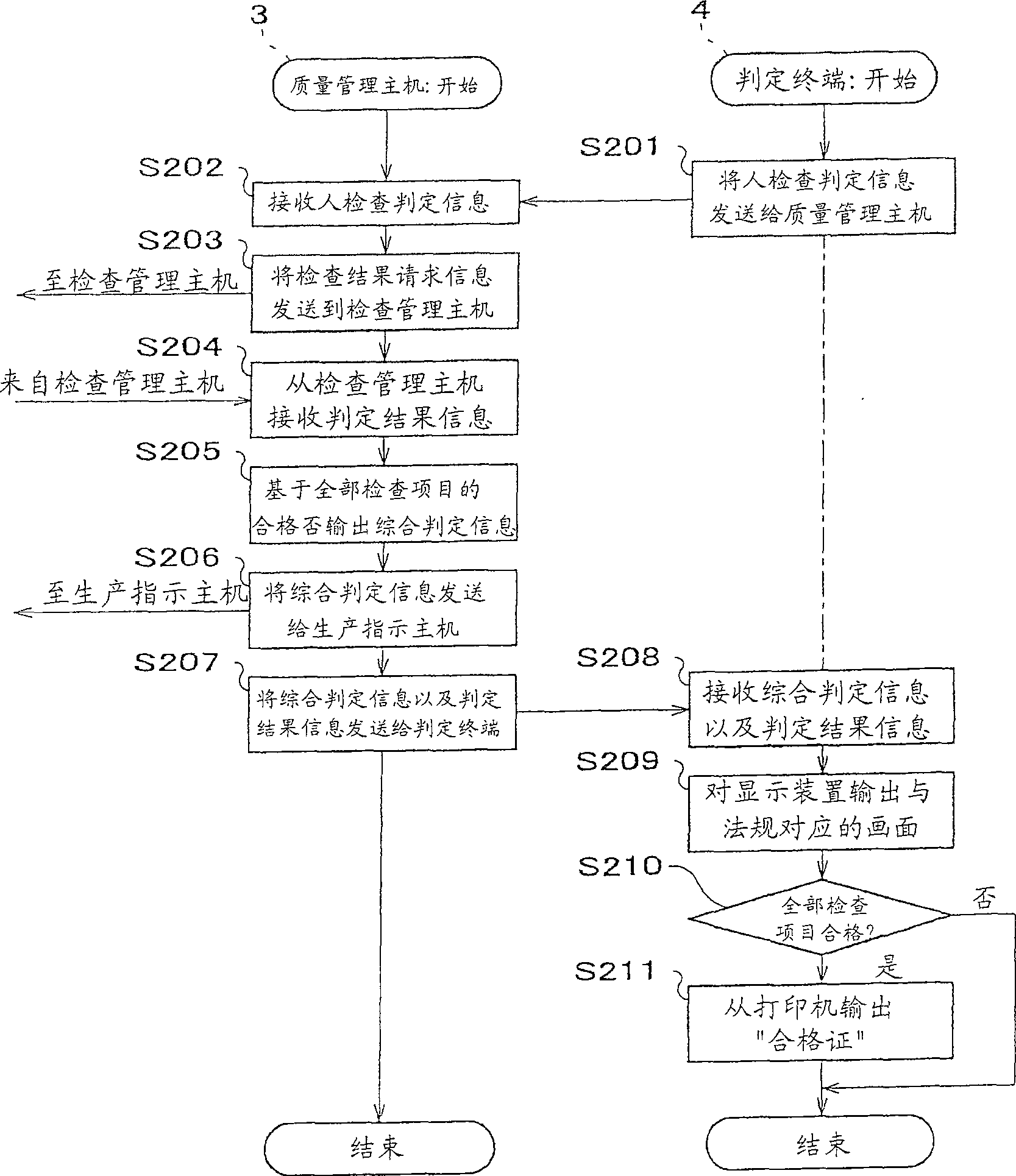

[0028] FIG. 1 is an explanatory diagram showing the concept of a finished vehicle inspection line in this embodiment. With reference to Fig. 1, the completed car inspection line of the present embodiment is mainly composed of the following processes: the human inspection process 14, for the completion of the assembly through the manufacturing processes such as welding, spraying, and assembly in the vehicle body assembly process 13 as the previous process. Car 17, the operator confirms the state of spraying and welding, etc.; automatic machine inspection process 15, performs inspections stipulated by laws and regulations such as positioning and discharge; human inspection is inappropriate adjustment process 18, adjustment is inappropriate in the human inspection process 14 and the pass / fail judgment step...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com