Defective goods automatic sorting method and equipment for high-speed automated production line

An automatic production line and automatic sorting technology, applied in sorting, self-adaptive control, special data processing applications, etc., can solve problems that affect the health of inspectors, environmental pollution, and the speed of shooting is not very fast, etc., to reduce the technical The cost of promotion and update, the avoidance of environmental pollution, and the effect of facilitating promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

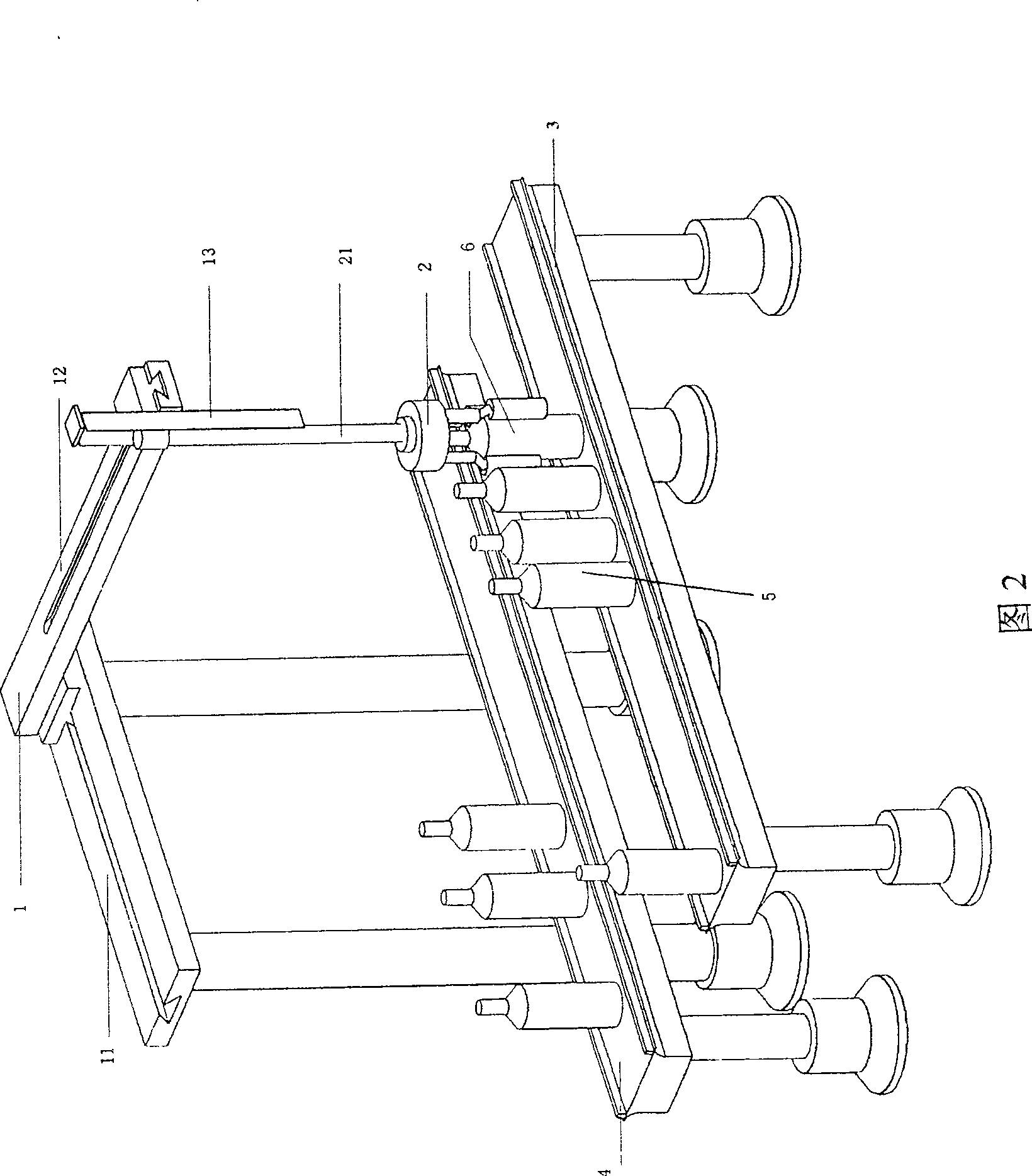

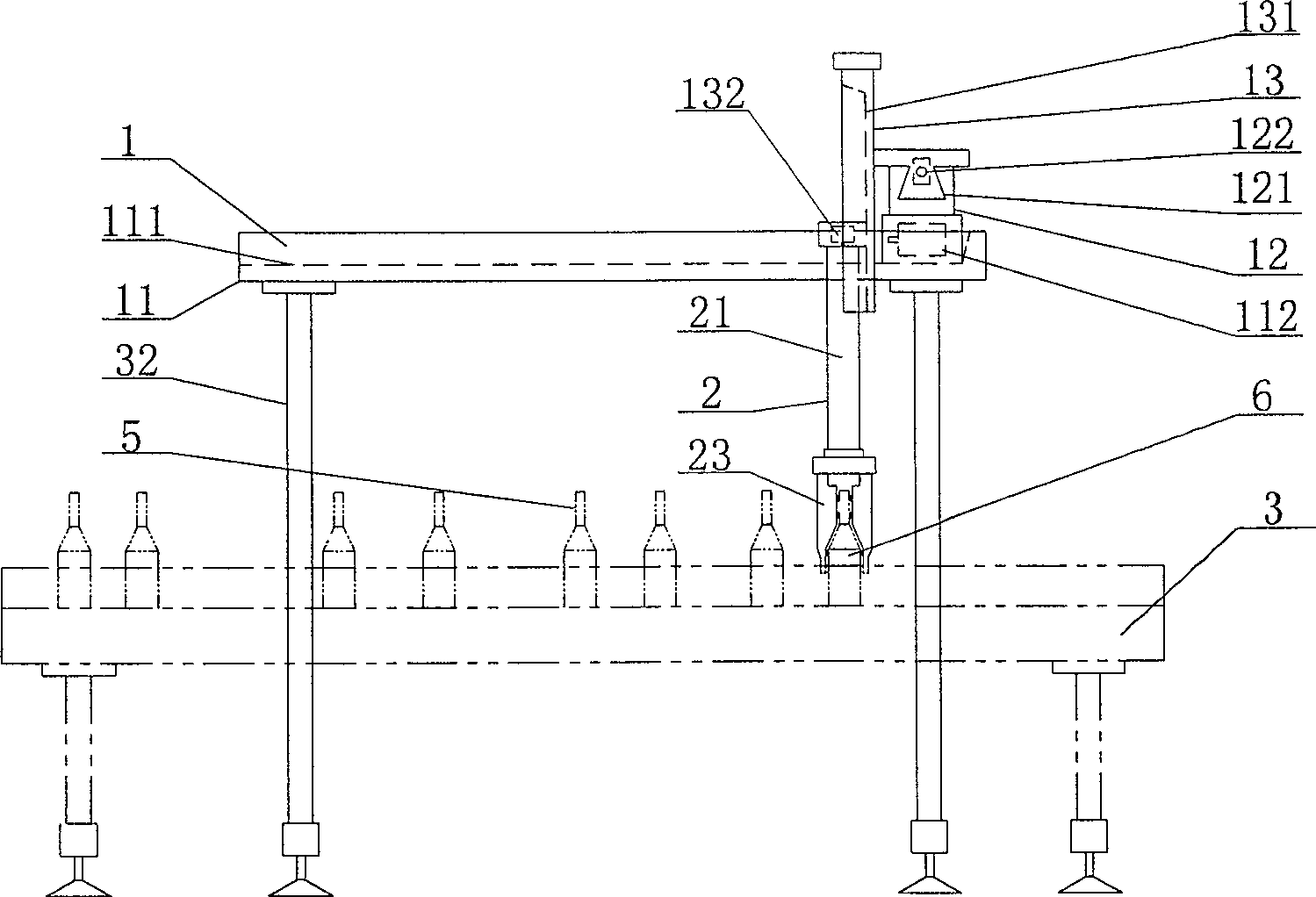

[0089] The present invention will be described in further detail below in conjunction with the accompanying drawings.

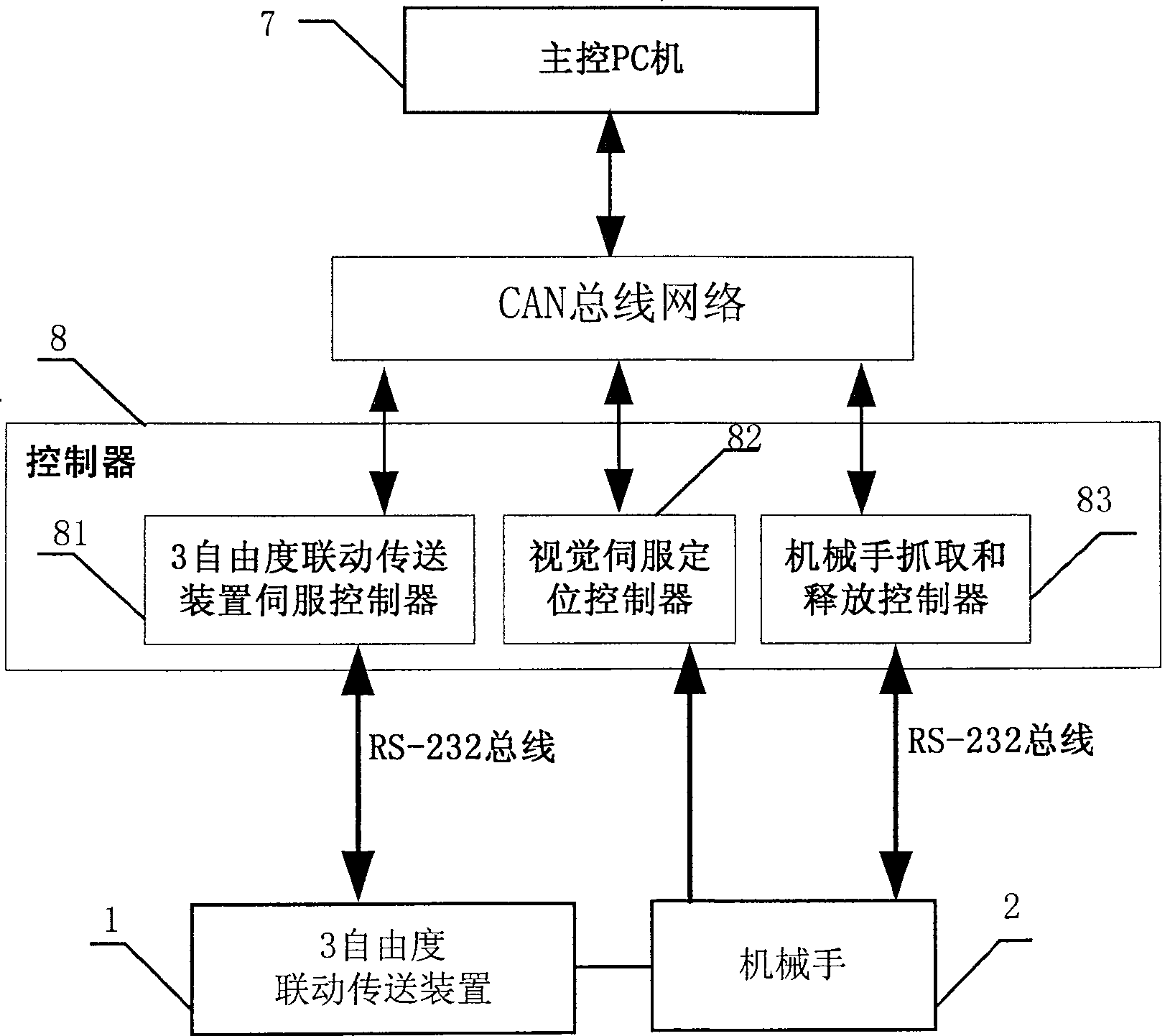

[0090] Based on technologies such as machine vision, intelligent control, and multi-sensor fusion detection control, the present invention proposes an automatic sorting method and equipment for defective products on a high-speed automated production line, and realizes high-speed intelligent grasping and sorting of defective products on a high-speed automated production line.

[0091] The method for automatic sorting of defective products on the high-speed automatic production line of the present invention is that after the defective product sorting system of the production line receives the defective product sorting signal, the 3-degree-of-freedom linkage transmission device set in the system is started to quickly position the manipulator to the defective product. Directly above, it keeps moving at the same speed as the conveyor belt of the product production ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com