Magnetically passive position sensor, method for manufacturing the magnetically passive position sensor

A sensor and magnetic technology, which is used in the use of electric/magnetic devices to transmit sensing components, convert sensor outputs, float level indicators, etc. , the effect of high magnetic field strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

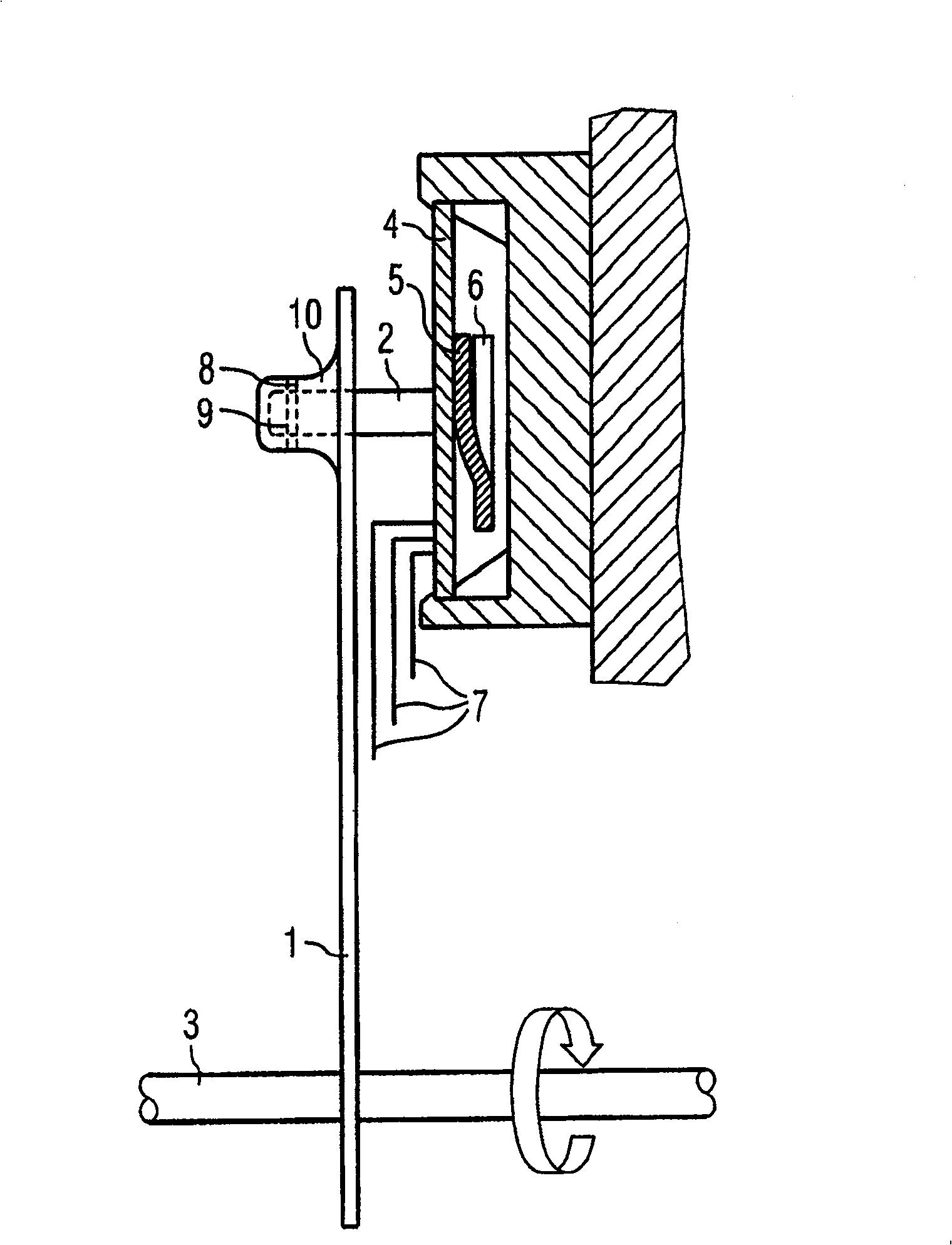

[0016] figure 1 A position sensor is shown with a magnet 2 arranged on a pivot arm 1 . The pivot arm 1 is fixed on the rotation axis 3 . The axis of rotation 3 may be connected to a buoy (not shown) of a liquid level sensor, eg in a motor vehicle fuel tank. The magnet 2 can pivot over the thick film mesh 4 . The magnetic contact spring elements 5 , 6 are arranged on the side of the thick-film mesh 4 facing away from the magnet 2 . The contact spring elements 5 , 6 can be attracted by the magnet 2 and pressed against the thick-film mesh 4 . The thick-film mesh 4 is connected by wires 7 to an electronic unit (not shown) which detects the position of the magnet 2 via contact spring elements 5 , 6 on the thick-film mesh 4 . This position sensor is described in detail in DE 19648539 A1, so that the descriptions therein with regard to possible design and function are hereby incorporated by reference.

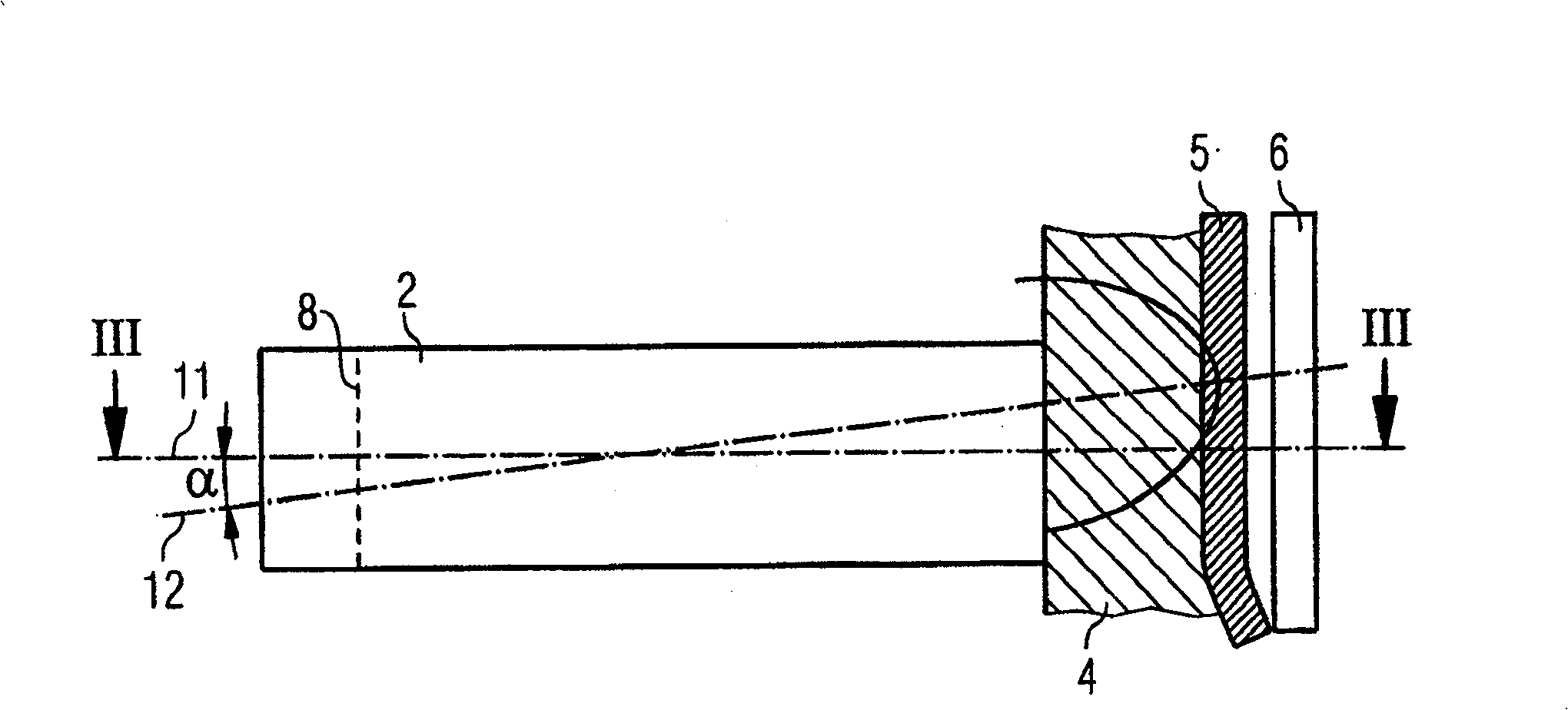

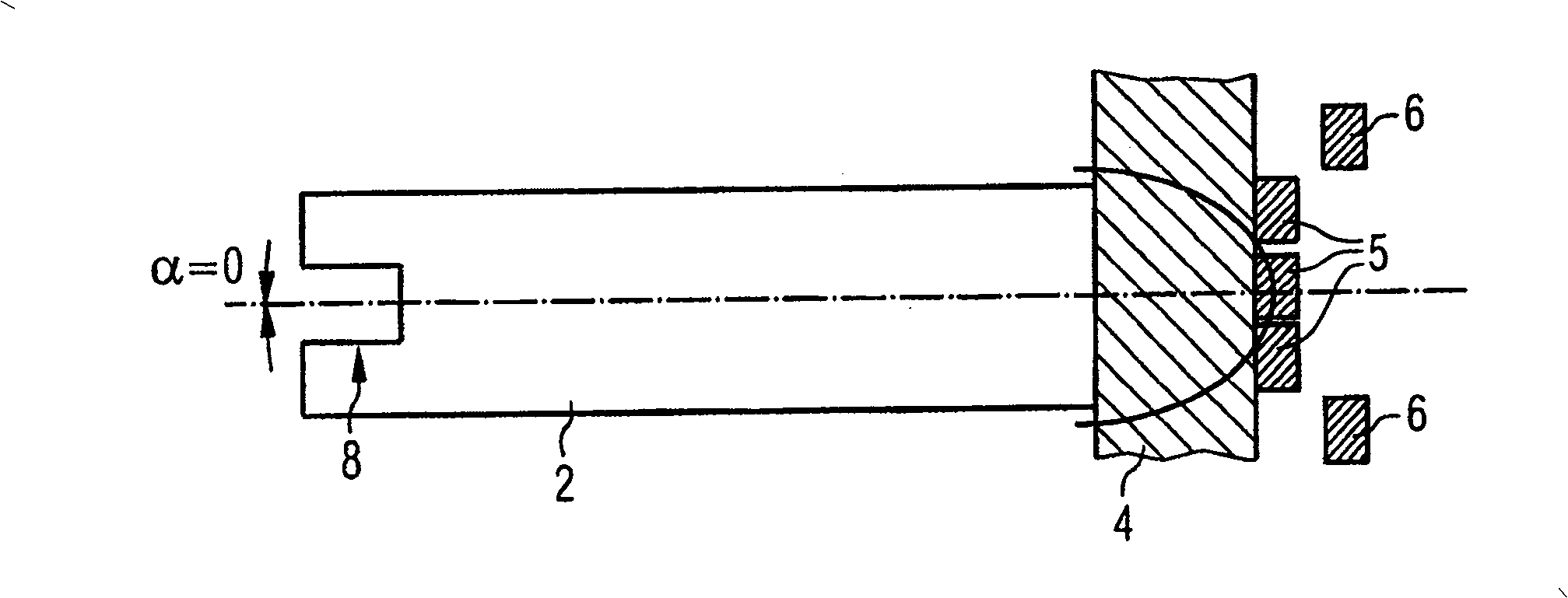

[0017] The magnet 2 has a guide polygon 8 , which is arranged on the end sid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com