Liquid crystal aberration correcting element

An aberration correction, liquid crystal technology, applied in optics, beam sources, instruments, etc., can solve the problems of large aberration, difficult to obtain phase difference, no complete aberration correction, etc., to achieve the effect of correcting deformation and improving accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

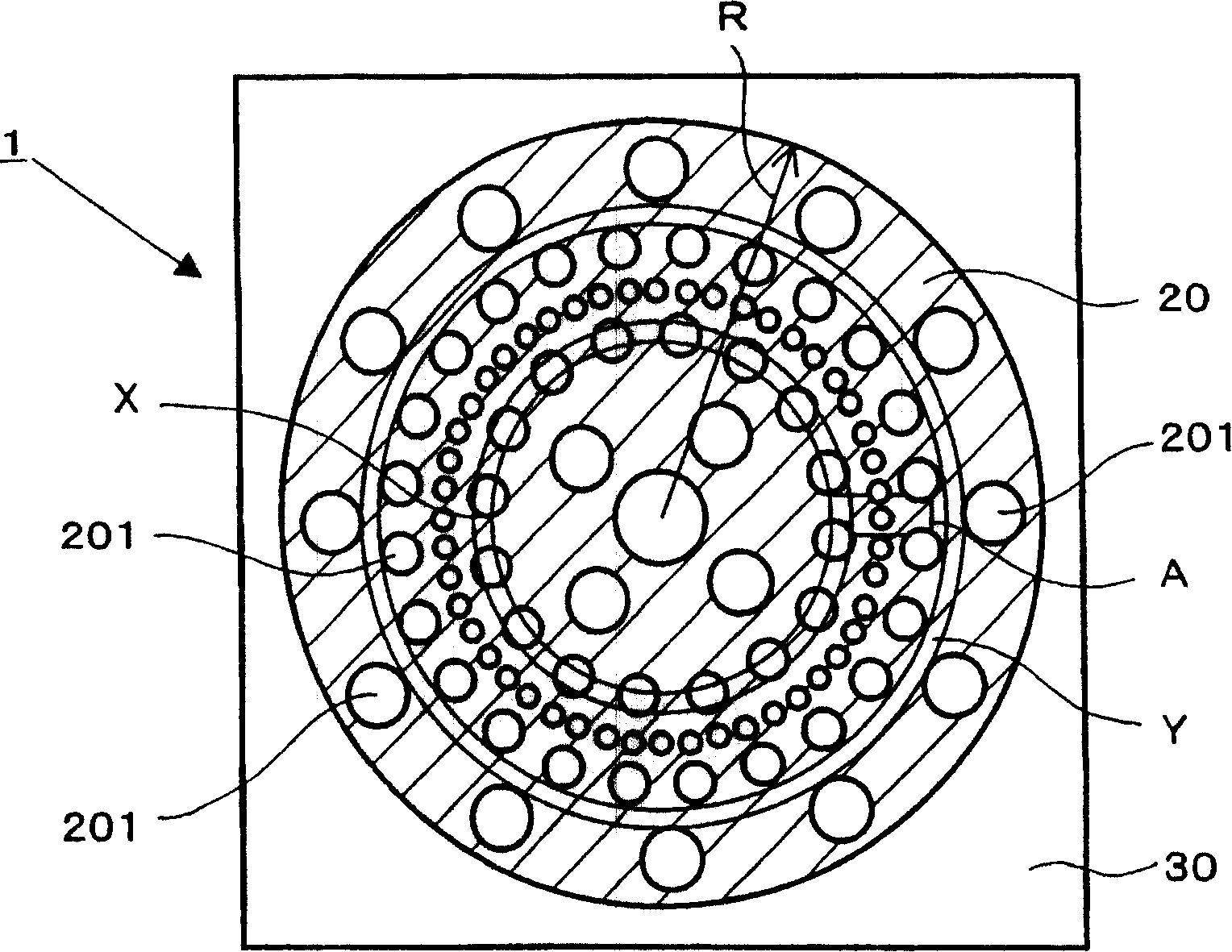

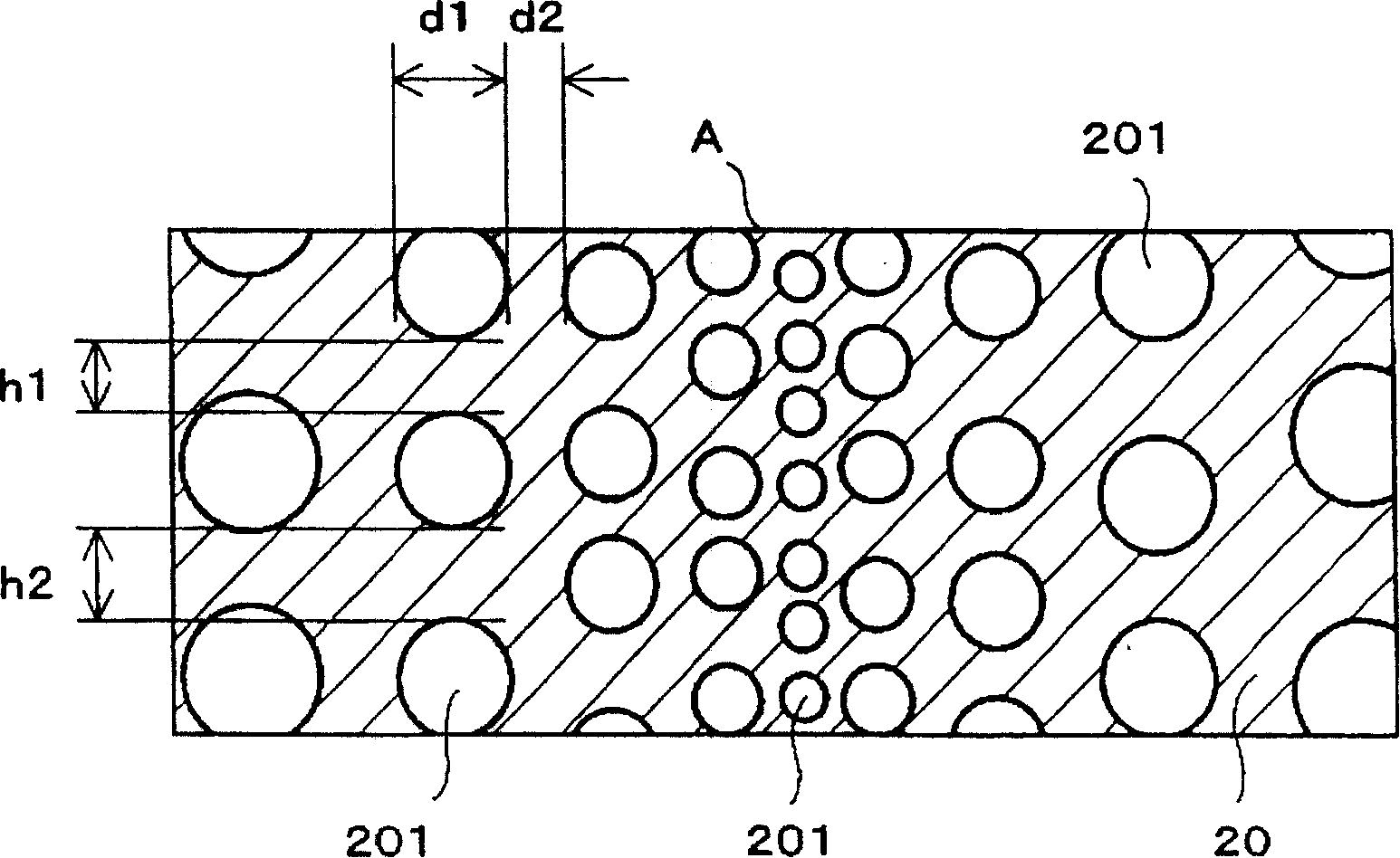

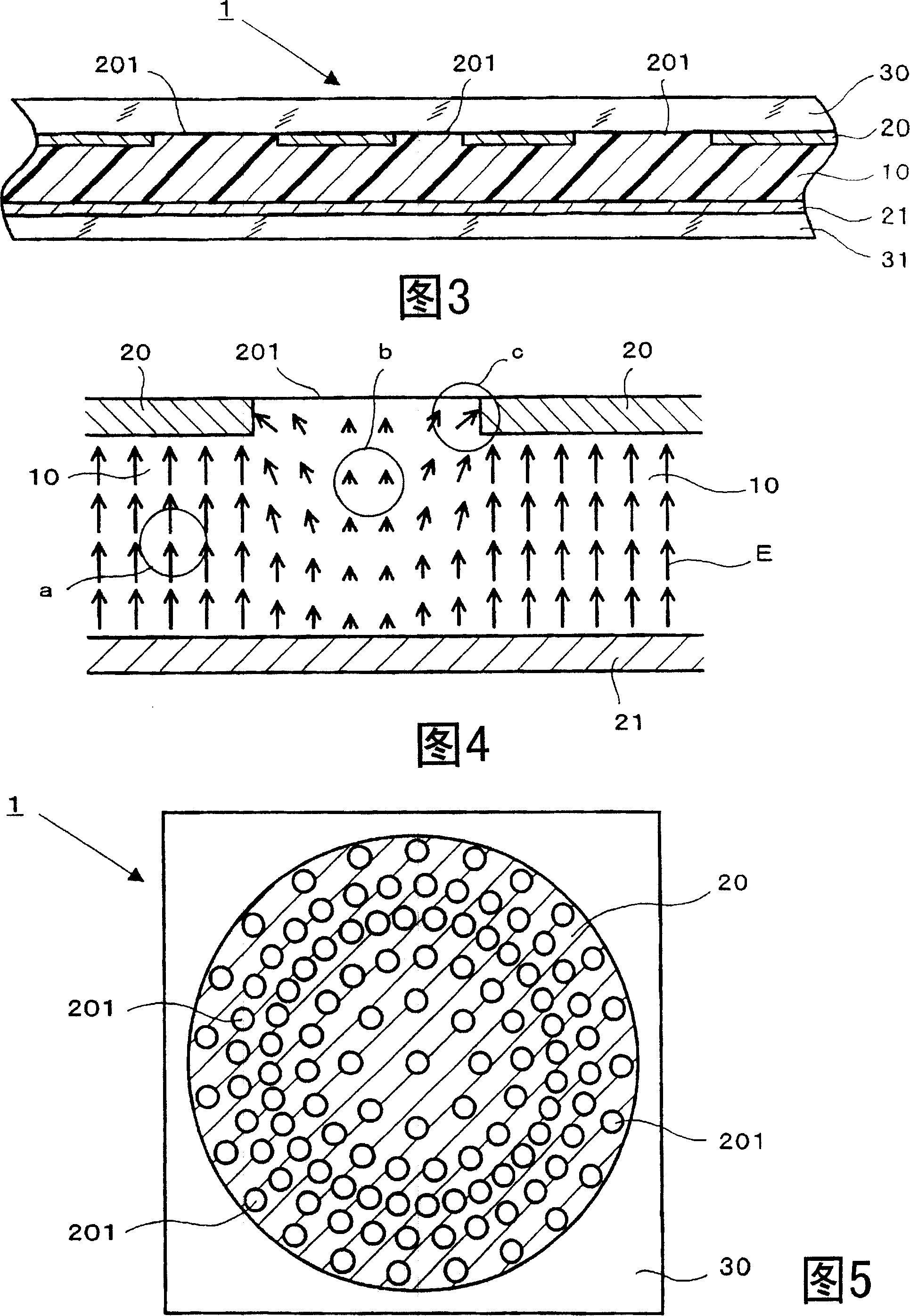

[0044] The present invention provides a liquid crystal aberration correction element having a structure including a liquid crystal and a plurality of electrodes facing each other across the liquid crystal, and a plurality of non-electrode portions where no electrode material is present are formed on at least one of the electrodes On the inside of the non-electrode part, the liquid crystal is not uniformly oriented when a voltage is applied, the shape of the non-electrode part is circular, and the diameter and arrangement interval of a plurality of non-electrode parts are divided into concentric circles along the electrode Change in the radial direction during the shape (first invention).

[0045] According to this structure, at the center of a plurality of non-electrode parts, the opposite electrode forms a weak electric field in the vertical direction, and at the end parts of the non-electrode parts, an electric field is formed in an oblique direction, so the electric field is di...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com