Cellophane is a regenerated cellulose film derived from natural sources such as wood pulp or cotton. First commercialized in the early 20th century, it was once the packaging material of choice—until plastics took over due to their strength and scalability. But now, with mounting global pressure to eliminate plastic waste and carbon emissions, cellophane is experiencing a renaissance.

Why? Because it’s compostable, renewable, transparent, and remarkably versatile. This blog explores how modern research is re-engineering cellophane to meet 21st-century demands, with applications ranging from zero-waste packaging to flexible electronics. We’ll examine its role across key sectors, its technical mechanisms, emerging research trends, and the future potential of this classic material reimagined.

Material Composition & Key Properties

Cellophane is made by dissolving cellulose and regenerating it into thin, flexible films. Its core attributes include:

- Biodegradability: Breaks down naturally in soil and aquatic systems.

- Oxygen Barrier: Provides strong protection against gas transmission.

- Transparency & Gloss: Suitable for retail packaging and optical uses.

- Thermal Sealing Capability: Can be modified for heat-sealing applications.

- Chemical Reactivity: Enables surface coating and functionalization.

These properties make it an ideal platform for modification via nanomaterials, bio-coatings, or hybrid structures.

Application Domains

🌱 Sustainable & Eco-Friendly Packaging

Global packaging systems face increasing pressure to eliminate non-degradable materials and embrace circular economy practices. While single-use plastics remain functional, they contribute heavily to microplastic pollution and climate impact. Cellophane provides a compostable, renewable, and low-toxicity alternative that aligns with zero-waste initiatives. It can be recycled or safely degraded after use, and its oxygen barrier and clarity make it well-suited for food, retail, and personal care packaging.

Current Research:

Innovations target compostable coatings, enhanced recyclability, and improved lifecycle emissions. Hybrid formulations combining cellophane with biodegradable polymers like starch and PVA are under exploration to boost moisture resistance while retaining eco-friendliness.

Explore More in:

- Future of Cellophane in Sustainable Packaging

- Cellophane’s Role in Zero-Waste Packaging Solutions

- Eco-Engineering Cellophane for Reduced Carbon Footprint

- Exploring Cellophane’s Impact on Global Sustainability Goals

- How to Ensure Biodegradability in Cellophane Production?

- How to Integrate Circular Economy Approaches in Cellophane?

⚙️ Barrier Enhancement & Material Durability

Advanced packaging must protect against moisture, oxidation, UV exposure, and contamination without relying on multilayer plastics that hinder recycling. Cellophane naturally offers good gas barrier properties and transparency. Researchers enhance its water resistance, sealability, and thermal endurance through coatings and additives like beeswax, chitosan, or clay nanoparticles, maintaining biodegradability while improving performance.

Current Research:

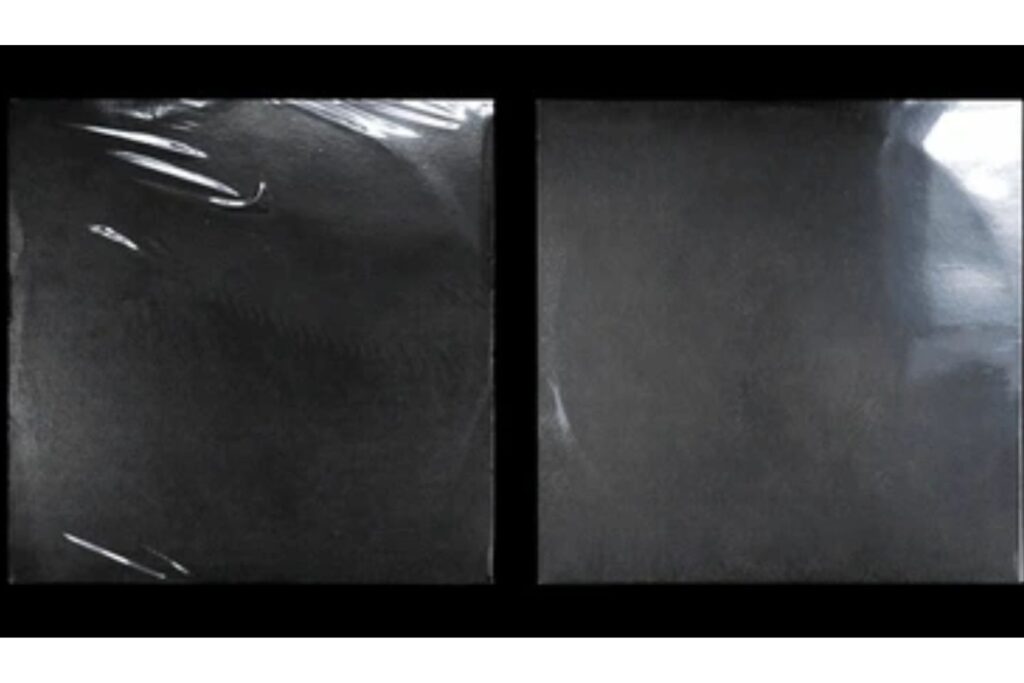

Ongoing work focuses on improving tensile strength, anti-fog performance, and stretchability. Nanostructuring and plasma treatments enable smart surface behaviors such as condensation resistance and improved adhesion to compostable layers.

Explore More in:

- How to Optimize Moisture Resistance in Cellophane?

- Advanced Solutions in Antimicrobial Cellophane Films

- How to Boost Heat-Sealability of Cellophane?

- How to Improve Aroma Retention in Cellophane Products?

- How to Develop Robust Anti-Fogging Cellophane?

- Cellophane Films: Innovations in Heat Resistance

- How to Achieve High Stretchability in Cellophane Materials?

🧪 Functional Coatings & Composite Innovation

From food wraps to electronics, there is a growing need for materials that not only protect but also perform with electrical conductivity, antibacterial action, or smart responsiveness. Cellophane acts as a responsive base for coatings and blending. Functional layers—whether hydrophobic, UV-blocking, or antimicrobial—can be sustainably applied, and cellophane serves as a matrix for nanocomposites, enabling new sensor and flexible electronics applications.

Current Research:

Biocomposites incorporating nanocellulose, graphene oxide, and metal oxides are under development. Multilayer laminates improve durability, and spray coatings allow real-time performance tuning. AI-aided material modeling is beginning to assist in cellophane formulation design.

Explore More in:

- Enhancing Cellophane Through Bio-Composite Technology

- Cellophane Coatings for Improved Barrier Properties

- How to Innovate with Blended Cellophane Formulations?

- Breakthrough Innovations in Heat-Resistant Cellophane

- Innovations in Multi-Layered Cellophane Structures

- Emerging Techniques in Nano-Cellophane Film Production

- Cellophane: Innovations for Enhanced Electrical Conductivity

🧬 Biomedical, Acoustic & Specialized Uses

Biomedical devices, cosmetics, and audio engineering require biocompatible, breathable, and safe materials. Plastics can cause irritation or contamination in these sensitive areas. Cellophane’s nontoxic, low-friction, and breathable qualities support wound dressings, drug delivery wraps, and acoustic membranes. It is also compatible with conductive polymers, enabling low-cost medical sensors and implantable wraps.

Current Research:

Applications in regenerative medicine, tissue-compatible adhesives, and cosmetic masks are emerging. Researchers utilize cellophane’s porous structure for controlled-release and insulation. Audio engineers investigate cellophane as a membrane in high-fidelity sound devices.

Explore More in:

- Cellophane in Biomedical Applications: A Future Outlook

- Cellophane for Performance Enhancement in Audio Applications

- Cellophane’s Viability in Photovoltaic Energy Solutions

- Cellophane’s Application in Innovative Textiles

- Emerging Cellophane Applications in the Cosmetic Industry

- The Role of Cellophane in Next-Gen Medical Products

📦 Smart Packaging & Transparent Electronics

Smart labeling, transparent displays, and IoT-integrated packaging demand flexible, optically clear, sustainable, and sensor-compatible materials. Cellophane’s transparency and uniformity make it suitable as a substrate for thin-film electronics. It can carry conductive inks, RFID circuitry, and luminescent coatings, supporting next-generation displays and smart tracking systems.

Current Research:

Experimental films compatible with transparent OLEDs, AI-synthesized barrier coatings, and energy-harvesting layers are in development. Integration with machine learning models helps predict environmental responsiveness for freshness tracking and intelligent sealing.

Explore More in:

- Cellophane’s Future in Smart Packaging Innovations

- The Next Wave in Responsive Cellophane Technologies

- Emerging Trends in Transparent Cellophane Applications

- Advances in Cellophane’s Optical Clarity for Electronics

- New Paradigms in Cellophane’s Use in Organic Electronics

- The Influence of AI on Cellophane Manufacturing Processes

Comparative Advantages & Limitations

| Category | Strengths | Challenges |

|---|---|---|

| Environmental Performance | Fully biodegradable, compostable, derived from renewable sources | Limited resistance to moisture and high temperatures |

| Functional Adaptability | Supports coatings, composites, and conductive modifications | Requires careful formulation to maintain eco-profile |

| Processing & Compatibility | Works with existing coating/casting equipment | Mechanical fragility in untreated form |

| Optical Clarity | High transparency and gloss ideal for smart packaging and retail displays | Susceptible to UV degradation unless stabilized |

Future Outlook & Research Frontiers

Looking ahead, cellophane is poised to take a central role in:

- Smart biodegradable packaging with sensor functionality and shelf-life tracking

- Biocompatible electronics for wearable devices and implantable medical sensors

- Circular supply chain materials that align with global sustainability goals

- High-barrier, multilayer composites for food, pharma, and electronics

- AI-aided material design to accelerate cellophane customization

Commercial breakthroughs will rely on improving processing scalability, mechanical durability, and regulatory alignment across regions.

Conclusion

Cellophane is more than just a nostalgic material—it’s a modern platform for sustainable innovation. With its natural origin, versatility, and functional modifiability, it supports next-generation developments in packaging, healthcare, and electronics. Whether you’re designing a compostable food wrap or a transparent OLED substrate, cellophane offers a path forward.

Now is the time for researchers, engineers, and product developers to re-evaluate this classic material with modern tools—and unlock its full potential in the circular economy.

Accelerate Cellophane Innovation with PatSnap Eureka AI Agent

The cellophane landscape is expanding fast. PatSnap Eureka AI Agent PatSnap Eureka AI Agent helps R&D teams uncover white space opportunities, benchmark innovation strategies, and visualize global patent landscapes in sustainable materials.

👉 Book your free PatSnap Eureka AI Agent demo today and bring your cellophane-based innovations to market faster and smarter.