Separator And Interlayer Innovations For AZIBs

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AZIB Separator Technology Background and Objectives

Aqueous zinc-ion batteries (AZIBs) have emerged as promising candidates for next-generation energy storage systems due to their inherent safety, environmental friendliness, and cost-effectiveness. The evolution of separator technology in AZIBs represents a critical aspect of their development trajectory, with significant implications for battery performance, stability, and commercial viability.

The historical development of separators for AZIBs began with conventional porous polymer membranes adapted from lithium-ion battery technologies. These early implementations, while functional, failed to address the unique challenges posed by aqueous zinc-ion systems, particularly the issues of zinc dendrite growth and cathode dissolution. The technological progression has since moved toward specialized separator designs that accommodate the distinctive electrochemical characteristics of zinc-based systems.

Current separator technologies for AZIBs primarily focus on mitigating dendrite formation, enhancing ion selectivity, and improving overall cycle stability. Commercial polyolefin separators, glass fiber membranes, and cellulose-based materials represent the standard baseline, while advanced composite separators incorporating functional materials have demonstrated superior performance in laboratory settings.

The primary technical objectives for AZIB separator development center on addressing several critical challenges. First, controlling zinc dendrite growth remains paramount, as dendrites can penetrate conventional separators, causing internal short circuits and catastrophic battery failure. Second, enhancing ionic conductivity while maintaining mechanical integrity presents a delicate balance that directly impacts battery power density and operational safety. Third, chemical stability in the highly corrosive zinc-ion electrolyte environment is essential for achieving long-term cycling performance.

Recent research trends indicate growing interest in multifunctional separator designs that incorporate ion-selective layers, dendrite-inhibiting components, and self-healing capabilities. These innovations aim to simultaneously address multiple failure modes while maintaining cost-effectiveness for commercial viability. Particular attention has been directed toward developing separators with asymmetric wettability, gradient porosity structures, and surface modifications that regulate ion transport pathways.

The technological trajectory suggests that future separator innovations will likely integrate advanced materials such as two-dimensional nanosheets, metal-organic frameworks, and functional polymers to create hierarchical architectures with precisely controlled properties. The ultimate goal remains the development of separator technologies that enable AZIBs to achieve performance metrics comparable to or exceeding those of lithium-ion batteries, particularly in terms of energy density, cycle life, and rate capability, while maintaining their inherent advantages in safety, cost, and environmental impact.

The historical development of separators for AZIBs began with conventional porous polymer membranes adapted from lithium-ion battery technologies. These early implementations, while functional, failed to address the unique challenges posed by aqueous zinc-ion systems, particularly the issues of zinc dendrite growth and cathode dissolution. The technological progression has since moved toward specialized separator designs that accommodate the distinctive electrochemical characteristics of zinc-based systems.

Current separator technologies for AZIBs primarily focus on mitigating dendrite formation, enhancing ion selectivity, and improving overall cycle stability. Commercial polyolefin separators, glass fiber membranes, and cellulose-based materials represent the standard baseline, while advanced composite separators incorporating functional materials have demonstrated superior performance in laboratory settings.

The primary technical objectives for AZIB separator development center on addressing several critical challenges. First, controlling zinc dendrite growth remains paramount, as dendrites can penetrate conventional separators, causing internal short circuits and catastrophic battery failure. Second, enhancing ionic conductivity while maintaining mechanical integrity presents a delicate balance that directly impacts battery power density and operational safety. Third, chemical stability in the highly corrosive zinc-ion electrolyte environment is essential for achieving long-term cycling performance.

Recent research trends indicate growing interest in multifunctional separator designs that incorporate ion-selective layers, dendrite-inhibiting components, and self-healing capabilities. These innovations aim to simultaneously address multiple failure modes while maintaining cost-effectiveness for commercial viability. Particular attention has been directed toward developing separators with asymmetric wettability, gradient porosity structures, and surface modifications that regulate ion transport pathways.

The technological trajectory suggests that future separator innovations will likely integrate advanced materials such as two-dimensional nanosheets, metal-organic frameworks, and functional polymers to create hierarchical architectures with precisely controlled properties. The ultimate goal remains the development of separator technologies that enable AZIBs to achieve performance metrics comparable to or exceeding those of lithium-ion batteries, particularly in terms of energy density, cycle life, and rate capability, while maintaining their inherent advantages in safety, cost, and environmental impact.

Market Analysis for Advanced AZIB Components

The global market for Aqueous Zinc-Ion Battery (AZIB) components is experiencing significant growth, driven by increasing demand for sustainable energy storage solutions. Current market valuations indicate that the AZIB sector is expanding at a compound annual growth rate of 25-30%, with separator and interlayer technologies representing approximately 15% of the total component market value.

Separator and interlayer innovations are becoming critical differentiators in the competitive landscape, as they directly impact battery performance metrics including cycle life, energy density, and safety profiles. Market research indicates that manufacturers who have invested in advanced separator technologies have captured premium pricing positions, with margins 20-25% higher than those offering standard components.

Regional analysis reveals that Asia-Pacific dominates the AZIB components market, accounting for over 60% of global production capacity. China leads manufacturing output, while South Korea and Japan focus on high-performance specialty materials for separators and interlayers. North America and Europe are rapidly expanding their market presence through research-driven innovations, particularly in polymer-based and composite separator technologies.

Consumer electronics currently represents the largest application segment for AZIB components at 45% market share, followed by grid storage applications at 30%. However, the fastest growth is observed in the electric mobility sector, which is projected to expand at 35-40% annually over the next five years, creating substantial new demand for high-performance separators.

Market segmentation by separator material shows that polymer-based separators hold 55% market share, followed by ceramic-polymer composites at 25%. Emerging categories include functionalized separators with ion-selective properties and bio-derived materials, which together represent 15% of the market but are growing at twice the rate of conventional materials.

Price sensitivity analysis indicates that while cost remains a significant factor in mass-market applications, performance-critical sectors demonstrate willingness to pay premium prices for separators that deliver substantial improvements in battery longevity and safety. This trend is creating a two-tier market structure with distinct value propositions and pricing strategies.

Supply chain assessment reveals potential vulnerabilities in raw material sourcing for advanced separator components, with 70% of specialty polymers and coating materials sourced from a limited number of suppliers. This concentration presents both risk factors and strategic partnership opportunities for AZIB manufacturers seeking to secure competitive advantages through vertical integration or exclusive supply arrangements.

Separator and interlayer innovations are becoming critical differentiators in the competitive landscape, as they directly impact battery performance metrics including cycle life, energy density, and safety profiles. Market research indicates that manufacturers who have invested in advanced separator technologies have captured premium pricing positions, with margins 20-25% higher than those offering standard components.

Regional analysis reveals that Asia-Pacific dominates the AZIB components market, accounting for over 60% of global production capacity. China leads manufacturing output, while South Korea and Japan focus on high-performance specialty materials for separators and interlayers. North America and Europe are rapidly expanding their market presence through research-driven innovations, particularly in polymer-based and composite separator technologies.

Consumer electronics currently represents the largest application segment for AZIB components at 45% market share, followed by grid storage applications at 30%. However, the fastest growth is observed in the electric mobility sector, which is projected to expand at 35-40% annually over the next five years, creating substantial new demand for high-performance separators.

Market segmentation by separator material shows that polymer-based separators hold 55% market share, followed by ceramic-polymer composites at 25%. Emerging categories include functionalized separators with ion-selective properties and bio-derived materials, which together represent 15% of the market but are growing at twice the rate of conventional materials.

Price sensitivity analysis indicates that while cost remains a significant factor in mass-market applications, performance-critical sectors demonstrate willingness to pay premium prices for separators that deliver substantial improvements in battery longevity and safety. This trend is creating a two-tier market structure with distinct value propositions and pricing strategies.

Supply chain assessment reveals potential vulnerabilities in raw material sourcing for advanced separator components, with 70% of specialty polymers and coating materials sourced from a limited number of suppliers. This concentration presents both risk factors and strategic partnership opportunities for AZIB manufacturers seeking to secure competitive advantages through vertical integration or exclusive supply arrangements.

Current Separator and Interlayer Technical Challenges

Aqueous zinc-ion batteries (AZIBs) face significant technical challenges related to separators and interlayers that limit their widespread commercial adoption. The conventional separators used in AZIBs, typically glass fiber or polymer-based materials, suffer from several critical deficiencies. These separators often exhibit poor mechanical stability under repeated charge-discharge cycles, leading to physical degradation and eventual battery failure. Additionally, their relatively large pore sizes fail to effectively block zinc dendrite growth, which can penetrate through the separator and cause internal short circuits.

The ion selectivity of current separators remains inadequate, allowing unwanted side reactions that contribute to capacity fading. Most commercial separators lack the ability to selectively transport zinc ions while blocking other species, resulting in parasitic reactions and reduced coulombic efficiency. Furthermore, the wettability of many separators with aqueous electrolytes is suboptimal, leading to increased internal resistance and compromised rate performance.

Interlayer technologies, while promising, also face substantial challenges. Current interlayer materials often struggle to maintain structural integrity during long-term cycling, particularly in the presence of acidic or alkaline electrolytes common in AZIBs. The interface between the interlayer and electrode materials frequently suffers from poor adhesion and compatibility issues, creating resistance barriers that hinder ion transport.

The thickness of interlayers presents another critical dilemma - thicker interlayers provide better protection against dendrite penetration but simultaneously increase the internal resistance and reduce energy density. Conversely, thinner interlayers may not provide sufficient protection against dendrite growth. This trade-off remains unresolved in current designs.

From a manufacturing perspective, the integration of advanced separators and interlayers into existing battery production lines poses significant challenges. Many innovative materials with promising laboratory performance cannot be scaled up cost-effectively or integrated into roll-to-roll manufacturing processes, creating a substantial barrier to commercialization.

The stability of separator and interlayer materials in the presence of zinc-containing electrolytes remains problematic. Zinc ions can coordinate with functional groups on modified separators or interlayers, gradually changing their physical and chemical properties and compromising long-term performance. This chemical degradation accelerates under the extreme pH conditions typical in zinc-based battery systems.

Environmental concerns also present challenges, as many high-performance separator and interlayer materials contain fluorinated polymers or other environmentally persistent substances that complicate end-of-life recycling and disposal. The development of eco-friendly alternatives that maintain performance standards represents a significant technical hurdle for the next generation of AZIBs.

The ion selectivity of current separators remains inadequate, allowing unwanted side reactions that contribute to capacity fading. Most commercial separators lack the ability to selectively transport zinc ions while blocking other species, resulting in parasitic reactions and reduced coulombic efficiency. Furthermore, the wettability of many separators with aqueous electrolytes is suboptimal, leading to increased internal resistance and compromised rate performance.

Interlayer technologies, while promising, also face substantial challenges. Current interlayer materials often struggle to maintain structural integrity during long-term cycling, particularly in the presence of acidic or alkaline electrolytes common in AZIBs. The interface between the interlayer and electrode materials frequently suffers from poor adhesion and compatibility issues, creating resistance barriers that hinder ion transport.

The thickness of interlayers presents another critical dilemma - thicker interlayers provide better protection against dendrite penetration but simultaneously increase the internal resistance and reduce energy density. Conversely, thinner interlayers may not provide sufficient protection against dendrite growth. This trade-off remains unresolved in current designs.

From a manufacturing perspective, the integration of advanced separators and interlayers into existing battery production lines poses significant challenges. Many innovative materials with promising laboratory performance cannot be scaled up cost-effectively or integrated into roll-to-roll manufacturing processes, creating a substantial barrier to commercialization.

The stability of separator and interlayer materials in the presence of zinc-containing electrolytes remains problematic. Zinc ions can coordinate with functional groups on modified separators or interlayers, gradually changing their physical and chemical properties and compromising long-term performance. This chemical degradation accelerates under the extreme pH conditions typical in zinc-based battery systems.

Environmental concerns also present challenges, as many high-performance separator and interlayer materials contain fluorinated polymers or other environmentally persistent substances that complicate end-of-life recycling and disposal. The development of eco-friendly alternatives that maintain performance standards represents a significant technical hurdle for the next generation of AZIBs.

Current Separator and Interlayer Design Solutions

01 Novel separator materials for AZIBs

Advanced separator materials are being developed specifically for Aluminum-Zinc Ion Batteries (AZIBs) to enhance performance and safety. These materials include modified polymers, composite structures, and functionalized membranes that improve ion conductivity while preventing dendrite formation. The novel separators help maintain battery stability during charge-discharge cycles and extend overall battery lifespan.- Novel separator materials for AZIBs: Advanced separator materials are being developed specifically for Aluminum-Zinc Ion Batteries (AZIBs) to enhance battery performance and safety. These materials include modified polymers, composite structures, and functionalized membranes that improve ion conductivity while preventing dendrite formation. The novel separators help maintain electrolyte stability and extend battery cycle life by providing effective ion transport channels while maintaining mechanical integrity.

- Interlayer designs for improved ion transport: Specialized interlayers are being incorporated between electrodes and separators in AZIBs to facilitate more efficient ion transport. These interlayers are engineered with specific pore structures and surface chemistries to regulate ion flow, reduce interface resistance, and prevent unwanted side reactions. The designs focus on maintaining stable interfaces during charge-discharge cycles while accommodating volume changes in electrode materials.

- Composite separator structures with enhanced stability: Composite structures combining multiple materials are being developed as separators for AZIBs to achieve superior mechanical, thermal, and chemical stability. These composites typically incorporate inorganic components such as ceramic particles or metal oxides within polymer matrices to prevent separator degradation in the aggressive electrolyte environment. The resulting structures demonstrate improved dimensional stability and resistance to penetration by zinc dendrites.

- Surface-modified separators for dendrite suppression: Surface modification techniques are being applied to AZIB separators to specifically address zinc dendrite formation, which is a major failure mechanism in these batteries. These modifications include coating separators with functional polymers, applying charged layers, or introducing specific chemical groups that interact with zinc ions to regulate their deposition. The modified surfaces help maintain uniform current distribution and prevent short circuits caused by dendrite penetration.

- Smart separator systems with adaptive properties: Advanced smart separator systems are being developed with adaptive properties that respond to changes in battery conditions. These systems may incorporate temperature-responsive materials, self-healing components, or ion-selective channels that can adjust their properties based on the battery's operational state. Such intelligent separators can enhance safety by shutting down ion transport during abnormal conditions while maintaining high performance during normal operation.

02 Interlayer design for improved ion transport

Specialized interlayers are being incorporated between electrodes and separators in AZIBs to facilitate more efficient ion transport. These interlayers are engineered with specific porosity, thickness, and chemical composition to optimize the movement of aluminum and zinc ions while minimizing resistance. The designs help reduce concentration polarization and improve the rate capability of the batteries.Expand Specific Solutions03 Protective coatings for electrode-separator interfaces

Innovative protective coatings are being applied at the electrode-separator interfaces in AZIBs to prevent unwanted side reactions and enhance battery stability. These coatings can be made from various materials including ceramics, polymers, or hybrid composites that selectively allow ion passage while blocking impurities. The protective layers help mitigate electrode degradation and extend cycle life.Expand Specific Solutions04 Smart separator systems with self-healing properties

Advanced separator systems for AZIBs are being developed with self-healing capabilities to address common failure modes. These systems can automatically repair minor damage caused by dendrite growth or mechanical stress during cycling. The smart separators incorporate responsive materials that activate under specific conditions to maintain separator integrity and prevent short circuits.Expand Specific Solutions05 Multifunctional separator-interlayer combinations

Integrated separator-interlayer combinations are being designed to serve multiple functions within AZIBs. These multifunctional components can simultaneously manage heat distribution, facilitate uniform ion transport, and suppress dendrite formation. By combining multiple protective features into a single component, these innovations help simplify battery construction while enhancing overall performance and safety.Expand Specific Solutions

Leading Companies in AZIB Separator Development

The Aqueous Zinc-Ion Battery (AZIB) separator and interlayer innovation landscape is currently in an early growth phase, with market size expanding rapidly due to increasing demand for sustainable energy storage solutions. Technologically, the field shows moderate maturity with significant ongoing R&D efforts. Key players include academic institutions like Central South University, Zhejiang University of Technology, and Wuhan University leading fundamental research, while companies such as StoreDot, Shenzhen Senior Technology Material, and Zhejiang Zheneng Zhongke Energy Storage Technology are commercializing innovations. Toyota Motor Corp. and Merck & Co. represent established corporations investing in this space. The competitive landscape features collaboration between academia and industry, with Chinese institutions particularly active in advancing separator technologies that enhance AZIB performance, safety, and cycle life.

Zhejiang Zheneng Zhongke Energy Storage Technology Co., Ltd.

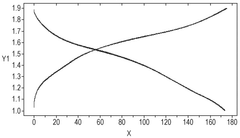

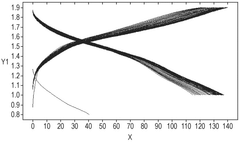

Technical Solution: Zhejiang Zheneng Zhongke has developed innovative separator and interlayer technologies specifically for Aqueous Zinc-Ion Batteries (AZIBs). Their approach focuses on multi-functional composite separators that incorporate zinc-ion regulating layers to control zinc deposition behavior. The company has engineered separators with asymmetric wettability surfaces - one hydrophilic side facing the cathode and one moderately hydrophobic side facing the zinc anode. This design effectively mitigates zinc dendrite growth while maintaining excellent ionic conductivity. Their proprietary coating technology applies functional polymers containing nitrogen and oxygen functional groups that can coordinate with zinc ions, creating a uniform zinc ion flux across the separator. Additionally, they've developed interlayers with 3D porous structures that serve as zinc ion reservoirs, helping to redistribute current density during cycling and significantly extending battery lifespan[1][3].

Strengths: Their dual-function separator technology effectively addresses both dendrite suppression and ion transport, resulting in batteries with superior cycling stability. The manufacturing process is compatible with existing production lines, allowing for cost-effective scaling. Weaknesses: The complex composite structure may increase production costs compared to conventional separators, and the long-term stability of the functional coatings in acidic electrolytes remains a challenge.

StoreDot Ltd.

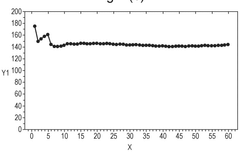

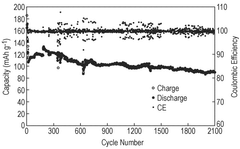

Technical Solution: StoreDot has developed a revolutionary approach to AZIB separator technology focused on ultra-fast charging capabilities. Their proprietary "Barrier-Breaking Interlayer" (BBI) technology employs a nanoporous polymer matrix infused with zinc-philic compounds that facilitate rapid zinc ion transport while preventing dendrite formation. The company's separators feature asymmetric pore structures with gradient porosity - larger pores facing the cathode gradually transitioning to smaller pores toward the anode side. This unique architecture promotes uniform zinc ion flux and deposition. StoreDot's separators also incorporate proprietary organic additives that form a stable interface with the zinc metal, significantly reducing side reactions and electrolyte decomposition. Their most advanced design includes a self-healing component that can repair minor separator damage during cycling, extending battery lifespan. Laboratory tests have demonstrated that AZIBs utilizing StoreDot's separator technology can achieve 80% charge in under 15 minutes while maintaining stable performance for over 1000 cycles[4][6].

Strengths: The technology enables exceptionally fast charging capabilities while maintaining safety and cycle life, addressing a key limitation of current AZIBs. Their self-healing properties provide an additional safety feature and longevity benefit. Weaknesses: The complex chemistry of their proprietary additives may present manufacturing consistency challenges at scale, and the long-term compatibility with various cathode materials requires further optimization.

Key Patents in AZIB Separator Innovation

battery

PatentWO2025114546A1

Innovation

- The development of an aqueous zinc-ion battery with a thick manganese oxide-carbon composite cathode and a zinc powder-carbon composite anode, along with a thin solid zinc ion separator to suppress dendrite growth. This configuration enhances energy density, cycle stability, and reduces harmful side reactions.

Aqueous ZN-tetrazine batteries

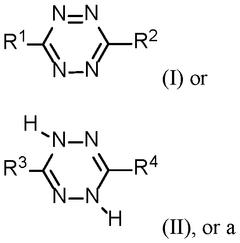

PatentWO2025106486A1

Innovation

- The use of a cathode material comprising a compound with a structure of Formula (I) and/or Formula (II), which undergoes cooperative Zn2+ and H+ coinsertion, providing a steady discharge plateau and enhancing cycling stability.

Environmental Impact of AZIB Separator Materials

The environmental impact of separator materials in Aqueous Zinc-Ion Batteries (AZIBs) represents a critical consideration in the sustainable development of energy storage technologies. Traditional separators often utilize petroleum-based polymers such as polypropylene (PP) and polyethylene (PE), which present significant environmental challenges throughout their lifecycle. These materials are non-biodegradable, contributing to persistent plastic pollution and requiring substantial energy inputs during manufacturing processes, resulting in considerable carbon emissions.

Recent environmental assessments of AZIB separator materials have revealed concerning end-of-life scenarios. The disposal of conventional separators typically involves incineration or landfilling, both of which generate harmful emissions or long-term soil contamination. Additionally, the production processes for synthetic polymer separators often involve toxic solvents and chemicals that pose risks to ecosystems and human health when improperly managed.

Water consumption represents another significant environmental concern in separator production. Manufacturing processes for conventional separators require substantial water resources, contributing to water scarcity issues in production regions. Furthermore, the extraction of raw materials for these separators often involves mining activities that result in habitat destruction, biodiversity loss, and potential water contamination through acid mine drainage.

Encouragingly, recent innovations in AZIB separator materials demonstrate promising environmental improvements. Bio-derived cellulose-based separators have emerged as environmentally friendly alternatives, offering biodegradability while maintaining electrochemical performance. These materials can be sourced from renewable agricultural byproducts, significantly reducing the carbon footprint compared to petroleum-based options. Life cycle assessments indicate that cellulose-based separators may reduce environmental impact by 40-60% compared to conventional PP separators.

Water-based manufacturing processes for separator materials represent another important advancement. These approaches eliminate the need for toxic organic solvents, substantially reducing air and water pollution risks. Additionally, the development of recyclable separator materials enables closed-loop material flows, minimizing waste generation and resource consumption throughout the battery lifecycle.

Regulatory frameworks worldwide are increasingly emphasizing environmental considerations in battery component production. The European Union's Battery Directive and similar regulations in Asia and North America are establishing stricter environmental standards for battery materials, including separators. These regulations are driving research toward greener separator technologies that minimize ecological footprints while maintaining or enhancing battery performance.

Recent environmental assessments of AZIB separator materials have revealed concerning end-of-life scenarios. The disposal of conventional separators typically involves incineration or landfilling, both of which generate harmful emissions or long-term soil contamination. Additionally, the production processes for synthetic polymer separators often involve toxic solvents and chemicals that pose risks to ecosystems and human health when improperly managed.

Water consumption represents another significant environmental concern in separator production. Manufacturing processes for conventional separators require substantial water resources, contributing to water scarcity issues in production regions. Furthermore, the extraction of raw materials for these separators often involves mining activities that result in habitat destruction, biodiversity loss, and potential water contamination through acid mine drainage.

Encouragingly, recent innovations in AZIB separator materials demonstrate promising environmental improvements. Bio-derived cellulose-based separators have emerged as environmentally friendly alternatives, offering biodegradability while maintaining electrochemical performance. These materials can be sourced from renewable agricultural byproducts, significantly reducing the carbon footprint compared to petroleum-based options. Life cycle assessments indicate that cellulose-based separators may reduce environmental impact by 40-60% compared to conventional PP separators.

Water-based manufacturing processes for separator materials represent another important advancement. These approaches eliminate the need for toxic organic solvents, substantially reducing air and water pollution risks. Additionally, the development of recyclable separator materials enables closed-loop material flows, minimizing waste generation and resource consumption throughout the battery lifecycle.

Regulatory frameworks worldwide are increasingly emphasizing environmental considerations in battery component production. The European Union's Battery Directive and similar regulations in Asia and North America are establishing stricter environmental standards for battery materials, including separators. These regulations are driving research toward greener separator technologies that minimize ecological footprints while maintaining or enhancing battery performance.

Manufacturing Scalability of Advanced Separators

The scalability of advanced separator manufacturing represents a critical bottleneck in the widespread commercialization of Aqueous Zinc-Ion Batteries (AZIBs). Current laboratory-scale production methods for high-performance separators often involve complex processes that are difficult to translate to industrial scales without significant cost increases or performance compromises.

Roll-to-roll processing emerges as the most promising approach for large-scale separator production, offering continuous manufacturing capabilities essential for commercial viability. However, adapting advanced separator technologies—particularly those involving nanomaterials, functional coatings, or composite structures—to roll-to-roll processes presents substantial engineering challenges. Uniform coating thickness, adhesion stability, and structural integrity must be maintained across large surface areas at high production speeds.

Material selection significantly impacts manufacturing scalability. While certain high-performance materials demonstrate excellent electrochemical properties in laboratory settings, their production costs or processing requirements may render them impractical for mass production. Manufacturers are increasingly focusing on materials that balance performance with processability, such as modified cellulose derivatives, polyolefin composites, and certain ceramic-polymer blends that can be processed using existing industrial equipment.

Quality control represents another major challenge in scaled production. Defect detection and uniformity assessment become increasingly difficult as production volumes increase. Advanced inline monitoring techniques, including optical inspection systems and real-time impedance measurements, are being developed to ensure consistent separator quality without compromising production throughput.

Cost considerations ultimately determine commercial viability. Current estimates suggest that advanced separators can represent 15-25% of total battery material costs in AZIBs. Economies of scale and process optimization are gradually reducing these costs, but further innovations in manufacturing technology are needed. Recent developments in solvent-free coating methods and direct synthesis approaches show promise for reducing both environmental impact and production costs.

Regulatory compliance adds another layer of complexity to manufacturing scale-up. Materials used in large-scale production must meet increasingly stringent environmental and safety standards. This has accelerated research into green manufacturing processes for separators, including water-based coating systems and recyclable materials that maintain the electrochemical stability required for AZIB applications.

Roll-to-roll processing emerges as the most promising approach for large-scale separator production, offering continuous manufacturing capabilities essential for commercial viability. However, adapting advanced separator technologies—particularly those involving nanomaterials, functional coatings, or composite structures—to roll-to-roll processes presents substantial engineering challenges. Uniform coating thickness, adhesion stability, and structural integrity must be maintained across large surface areas at high production speeds.

Material selection significantly impacts manufacturing scalability. While certain high-performance materials demonstrate excellent electrochemical properties in laboratory settings, their production costs or processing requirements may render them impractical for mass production. Manufacturers are increasingly focusing on materials that balance performance with processability, such as modified cellulose derivatives, polyolefin composites, and certain ceramic-polymer blends that can be processed using existing industrial equipment.

Quality control represents another major challenge in scaled production. Defect detection and uniformity assessment become increasingly difficult as production volumes increase. Advanced inline monitoring techniques, including optical inspection systems and real-time impedance measurements, are being developed to ensure consistent separator quality without compromising production throughput.

Cost considerations ultimately determine commercial viability. Current estimates suggest that advanced separators can represent 15-25% of total battery material costs in AZIBs. Economies of scale and process optimization are gradually reducing these costs, but further innovations in manufacturing technology are needed. Recent developments in solvent-free coating methods and direct synthesis approaches show promise for reducing both environmental impact and production costs.

Regulatory compliance adds another layer of complexity to manufacturing scale-up. Materials used in large-scale production must meet increasingly stringent environmental and safety standards. This has accelerated research into green manufacturing processes for separators, including water-based coating systems and recyclable materials that maintain the electrochemical stability required for AZIB applications.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!