Cycle Life, Calendar Life, And Failure Modes In AZIBs

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

AZIB Technology Evolution and Research Objectives

Aqueous zinc-ion batteries (AZIBs) have emerged as a promising energy storage technology over the past decade, evolving from early experimental concepts to increasingly practical systems with commercial potential. The evolution of AZIB technology can be traced back to the fundamental research on zinc electrochemistry in aqueous electrolytes, which laid the groundwork for modern zinc-based battery systems. Initially, these batteries faced significant challenges related to zinc dendrite formation, limited cycle life, and cathode material instability in aqueous environments.

The technological trajectory of AZIBs has been marked by several key breakthroughs, particularly in cathode material development. Early research focused primarily on manganese-based cathodes, which demonstrated the feasibility of zinc-ion intercalation but suffered from structural instability during cycling. Subsequent advances introduced vanadium-based compounds, Prussian blue analogs, and organic cathode materials, each offering distinct advantages in terms of capacity, rate capability, or cycle stability.

Electrolyte innovation represents another critical aspect of AZIB evolution, with research progressing from simple zinc salt solutions to carefully engineered electrolyte systems incorporating additives to suppress hydrogen evolution, mitigate zinc dendrite formation, and stabilize the electrode-electrolyte interface. The introduction of "water-in-salt" electrolytes marked a paradigm shift, expanding the electrochemical stability window and enabling higher operating voltages.

The primary research objectives in the field of AZIB cycle life, calendar life, and failure modes center on addressing several persistent challenges. First, understanding and mitigating zinc anode degradation mechanisms, particularly dendrite formation and surface passivation, remains crucial for extending cycle life beyond current limitations. Second, elucidating the complex interactions between zinc ions and various cathode host structures is essential for designing materials with enhanced structural stability during repeated charge-discharge cycles.

Calendar life research aims to identify and address self-discharge mechanisms and chemical instabilities that occur during storage periods. This includes investigating corrosion processes, electrolyte decomposition, and gradual structural changes in electrode materials that contribute to capacity fade even when the battery is not in active use.

Failure mode analysis constitutes a comprehensive approach to identifying degradation pathways across different operating conditions. This encompasses accelerated aging studies, post-mortem analyses, and in-situ characterization techniques to monitor structural and chemical changes during cycling. The ultimate goal is to establish predictive models that can accurately forecast battery lifetime based on usage patterns and environmental factors.

The technological trajectory of AZIBs has been marked by several key breakthroughs, particularly in cathode material development. Early research focused primarily on manganese-based cathodes, which demonstrated the feasibility of zinc-ion intercalation but suffered from structural instability during cycling. Subsequent advances introduced vanadium-based compounds, Prussian blue analogs, and organic cathode materials, each offering distinct advantages in terms of capacity, rate capability, or cycle stability.

Electrolyte innovation represents another critical aspect of AZIB evolution, with research progressing from simple zinc salt solutions to carefully engineered electrolyte systems incorporating additives to suppress hydrogen evolution, mitigate zinc dendrite formation, and stabilize the electrode-electrolyte interface. The introduction of "water-in-salt" electrolytes marked a paradigm shift, expanding the electrochemical stability window and enabling higher operating voltages.

The primary research objectives in the field of AZIB cycle life, calendar life, and failure modes center on addressing several persistent challenges. First, understanding and mitigating zinc anode degradation mechanisms, particularly dendrite formation and surface passivation, remains crucial for extending cycle life beyond current limitations. Second, elucidating the complex interactions between zinc ions and various cathode host structures is essential for designing materials with enhanced structural stability during repeated charge-discharge cycles.

Calendar life research aims to identify and address self-discharge mechanisms and chemical instabilities that occur during storage periods. This includes investigating corrosion processes, electrolyte decomposition, and gradual structural changes in electrode materials that contribute to capacity fade even when the battery is not in active use.

Failure mode analysis constitutes a comprehensive approach to identifying degradation pathways across different operating conditions. This encompasses accelerated aging studies, post-mortem analyses, and in-situ characterization techniques to monitor structural and chemical changes during cycling. The ultimate goal is to establish predictive models that can accurately forecast battery lifetime based on usage patterns and environmental factors.

Market Demand Analysis for AZIB Energy Storage

The global energy storage market is witnessing a significant shift towards sustainable and efficient technologies, creating substantial opportunities for Aqueous Zinc-Ion Batteries (AZIBs). Current market analysis indicates that the energy storage sector is projected to grow at a compound annual growth rate of over 20% through 2030, driven primarily by renewable energy integration, grid stabilization requirements, and the electrification of transportation.

AZIBs are positioned to capture a growing segment of this market due to their inherent advantages over conventional lithium-ion batteries, particularly in stationary storage applications. The demand for safer energy storage solutions is escalating, especially following high-profile thermal runaway incidents with lithium-based systems. AZIBs offer an intrinsically safer chemistry that eliminates fire risks, addressing a critical market need in residential, commercial, and utility-scale applications.

Cost considerations are driving significant interest in zinc-based technologies. With raw material prices for lithium and cobalt experiencing volatility and supply constraints, the abundant and inexpensive nature of zinc (approximately one-thirtieth the cost of lithium) presents a compelling economic advantage. Market research indicates that total cost of ownership for energy storage systems could be reduced by 25-40% through AZIB implementation, particularly when lifecycle considerations are factored in.

The environmental sustainability segment represents another substantial market driver. Corporate and governmental commitments to carbon neutrality are creating demand for storage technologies with lower environmental footprints. AZIBs, with their non-toxic components and simpler recycling processes, align with these sustainability initiatives and emerging regulatory frameworks regarding battery end-of-life management.

Geographically, the most immediate market opportunities for AZIBs exist in regions with aggressive renewable energy targets and challenging environmental conditions. Southeast Asia, India, and parts of Africa represent high-potential markets where the combination of high temperatures, limited infrastructure, and rapid renewable deployment creates ideal conditions for AZIB adoption. These regions are projected to account for over 30% of new energy storage deployments in the coming decade.

The telecommunications sector presents a specialized but substantial market opportunity, with an estimated 4 million telecom towers globally requiring reliable backup power. The superior cycle life potential of AZIBs makes them particularly attractive for this application, where frequent cycling and minimal maintenance are critical requirements. Industry forecasts suggest this sector alone could represent a multi-billion dollar opportunity for advanced zinc-based storage technologies.

AZIBs are positioned to capture a growing segment of this market due to their inherent advantages over conventional lithium-ion batteries, particularly in stationary storage applications. The demand for safer energy storage solutions is escalating, especially following high-profile thermal runaway incidents with lithium-based systems. AZIBs offer an intrinsically safer chemistry that eliminates fire risks, addressing a critical market need in residential, commercial, and utility-scale applications.

Cost considerations are driving significant interest in zinc-based technologies. With raw material prices for lithium and cobalt experiencing volatility and supply constraints, the abundant and inexpensive nature of zinc (approximately one-thirtieth the cost of lithium) presents a compelling economic advantage. Market research indicates that total cost of ownership for energy storage systems could be reduced by 25-40% through AZIB implementation, particularly when lifecycle considerations are factored in.

The environmental sustainability segment represents another substantial market driver. Corporate and governmental commitments to carbon neutrality are creating demand for storage technologies with lower environmental footprints. AZIBs, with their non-toxic components and simpler recycling processes, align with these sustainability initiatives and emerging regulatory frameworks regarding battery end-of-life management.

Geographically, the most immediate market opportunities for AZIBs exist in regions with aggressive renewable energy targets and challenging environmental conditions. Southeast Asia, India, and parts of Africa represent high-potential markets where the combination of high temperatures, limited infrastructure, and rapid renewable deployment creates ideal conditions for AZIB adoption. These regions are projected to account for over 30% of new energy storage deployments in the coming decade.

The telecommunications sector presents a specialized but substantial market opportunity, with an estimated 4 million telecom towers globally requiring reliable backup power. The superior cycle life potential of AZIBs makes them particularly attractive for this application, where frequent cycling and minimal maintenance are critical requirements. Industry forecasts suggest this sector alone could represent a multi-billion dollar opportunity for advanced zinc-based storage technologies.

Current Status and Challenges in AZIB Lifecycle

Aqueous zinc-ion batteries (AZIBs) have emerged as promising candidates for large-scale energy storage systems due to their high safety, low cost, and environmental friendliness. However, the current state of AZIB technology faces significant challenges in terms of lifecycle performance and reliability. The global research community has made substantial progress in understanding the fundamental mechanisms governing AZIB performance, yet several critical issues remain unresolved.

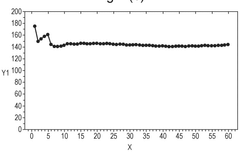

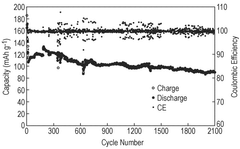

Recent studies indicate that AZIBs typically achieve 500-2000 cycles at moderate depths of discharge, significantly lower than the 5000+ cycles demonstrated by commercial lithium-ion batteries. This cycle life limitation stems primarily from the inherent instability of zinc metal anodes in aqueous electrolytes, where continuous dissolution/deposition processes lead to dendrite formation and capacity fading. Additionally, side reactions between zinc and water generate hydrogen evolution, further compromising long-term stability.

Calendar life investigations reveal that AZIBs suffer from self-discharge rates of 2-5% per month, with accelerated degradation at elevated temperatures. This phenomenon is attributed to the spontaneous corrosion of zinc anodes and the gradual dissolution of cathode materials in aqueous environments, even during idle periods. Such behavior presents a significant hurdle for applications requiring extended storage periods.

The geographical distribution of AZIB research shows concentration in East Asia (particularly China, Japan, and South Korea), North America, and Europe, with China leading in terms of patent applications and published research. This global effort has identified several failure modes specific to AZIBs, including zinc dendrite formation, cathode material dissolution, electrolyte depletion, and interfacial resistance growth.

Current technical constraints primarily revolve around the zinc anode's instability, with dendrite formation and hydrogen evolution representing the most pressing challenges. Various approaches to mitigate these issues include electrolyte additives, artificial solid-electrolyte interphases, and three-dimensional zinc host structures, yet none have completely resolved the fundamental instability of zinc in aqueous media.

On the cathode side, the dissolution of active materials during cycling remains problematic, particularly for manganese-based compounds that suffer from Mn2+ dissolution. This phenomenon not only reduces active material content but also leads to parasitic reactions at the anode surface, creating a complex degradation cycle that accelerates capacity fade.

Electrolyte innovation represents another critical challenge, as researchers struggle to develop formulations that simultaneously suppress hydrogen evolution, prevent cathode dissolution, and enable stable zinc plating/stripping. The delicate balance between pH, salt concentration, and additives remains difficult to optimize across the wide temperature and current density ranges required for practical applications.

Recent studies indicate that AZIBs typically achieve 500-2000 cycles at moderate depths of discharge, significantly lower than the 5000+ cycles demonstrated by commercial lithium-ion batteries. This cycle life limitation stems primarily from the inherent instability of zinc metal anodes in aqueous electrolytes, where continuous dissolution/deposition processes lead to dendrite formation and capacity fading. Additionally, side reactions between zinc and water generate hydrogen evolution, further compromising long-term stability.

Calendar life investigations reveal that AZIBs suffer from self-discharge rates of 2-5% per month, with accelerated degradation at elevated temperatures. This phenomenon is attributed to the spontaneous corrosion of zinc anodes and the gradual dissolution of cathode materials in aqueous environments, even during idle periods. Such behavior presents a significant hurdle for applications requiring extended storage periods.

The geographical distribution of AZIB research shows concentration in East Asia (particularly China, Japan, and South Korea), North America, and Europe, with China leading in terms of patent applications and published research. This global effort has identified several failure modes specific to AZIBs, including zinc dendrite formation, cathode material dissolution, electrolyte depletion, and interfacial resistance growth.

Current technical constraints primarily revolve around the zinc anode's instability, with dendrite formation and hydrogen evolution representing the most pressing challenges. Various approaches to mitigate these issues include electrolyte additives, artificial solid-electrolyte interphases, and three-dimensional zinc host structures, yet none have completely resolved the fundamental instability of zinc in aqueous media.

On the cathode side, the dissolution of active materials during cycling remains problematic, particularly for manganese-based compounds that suffer from Mn2+ dissolution. This phenomenon not only reduces active material content but also leads to parasitic reactions at the anode surface, creating a complex degradation cycle that accelerates capacity fade.

Electrolyte innovation represents another critical challenge, as researchers struggle to develop formulations that simultaneously suppress hydrogen evolution, prevent cathode dissolution, and enable stable zinc plating/stripping. The delicate balance between pH, salt concentration, and additives remains difficult to optimize across the wide temperature and current density ranges required for practical applications.

Current Methodologies for AZIB Lifecycle Assessment

01 Electrode materials for improved cycle life in AZIBs

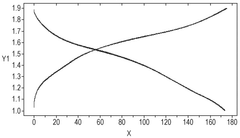

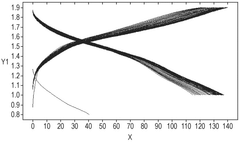

Various electrode materials can significantly enhance the cycle life of aqueous zinc-ion batteries. Advanced cathode materials such as manganese-based oxides, vanadium-based compounds, and Prussian blue analogs demonstrate superior cycling stability. Modified zinc anodes with protective coatings or dopants can mitigate dendrite formation and side reactions. These materials engineering approaches effectively address capacity fading issues during long-term cycling, enabling batteries to maintain performance over thousands of cycles.- Electrolyte optimization for improved cycle life: Optimizing electrolyte composition is crucial for enhancing the cycle life of AZIBs. This includes using additives to suppress zinc dendrite formation, adjusting salt concentrations to improve ionic conductivity, and incorporating stabilizers to prevent electrode degradation. Advanced electrolyte formulations can significantly extend battery lifespan by mitigating side reactions at electrode-electrolyte interfaces and maintaining stable zinc plating/stripping processes over numerous cycles.

- Electrode material engineering for durability: Engineering electrode materials is essential for addressing AZIB failure modes. This involves developing cathode materials with stable crystal structures that resist dissolution during cycling, creating anode materials that minimize dendrite formation, and designing interfaces that maintain structural integrity. Advanced nanostructured materials and composite electrodes can significantly improve cycle stability by providing robust ion diffusion pathways and accommodating volume changes during charge-discharge processes.

- Calendar life extension strategies: Extending the calendar life of AZIBs requires addressing self-discharge mechanisms and storage degradation. This includes developing passivation layers to protect electrodes during idle periods, implementing electrolyte formulations that remain stable over time, and designing battery management systems that monitor and control storage conditions. These strategies help maintain battery capacity during prolonged storage periods by preventing parasitic reactions that would otherwise gradually degrade battery components.

- Failure mode analysis and mitigation: Understanding and mitigating failure modes in AZIBs involves comprehensive analysis of degradation mechanisms. Key failure modes include zinc dendrite formation leading to short circuits, cathode material dissolution causing capacity fade, hydrogen evolution reactions resulting in pressure buildup, and electrode passivation limiting ion transport. Advanced diagnostic techniques and in-situ monitoring systems help identify these failure mechanisms, while protective coatings, structural buffers, and electrolyte additives can be implemented to address specific degradation pathways.

- Advanced testing protocols and performance evaluation: Developing standardized testing protocols is essential for accurately evaluating AZIB performance metrics. This includes accelerated aging tests to predict long-term behavior, cycling protocols that simulate real-world usage patterns, and analytical methods to quantify degradation mechanisms. Advanced characterization techniques such as electrochemical impedance spectroscopy, post-mortem analysis, and in-operando monitoring provide insights into battery health and degradation processes, enabling more accurate lifetime predictions and performance optimization.

02 Electrolyte optimization for extended calendar life

Electrolyte composition plays a crucial role in determining the calendar life of AZIBs. Additives such as organic molecules, polymers, and inorganic salts can stabilize the zinc/electrolyte interface, preventing parasitic reactions during storage. pH-adjusted electrolytes reduce corrosion and hydrogen evolution. Highly concentrated electrolytes or those with water-in-salt configurations minimize water activity and associated degradation mechanisms, thereby extending the shelf life and idle-state stability of zinc-ion batteries.Expand Specific Solutions03 Failure modes and degradation mechanisms in AZIBs

Common failure modes in aqueous zinc-ion batteries include zinc dendrite formation, cathode dissolution, hydrogen evolution, and electrolyte depletion. Dendrites can cause internal short circuits, while cathode materials may gradually dissolve into the electrolyte during cycling. Side reactions like hydrogen evolution consume active materials and increase internal pressure. Parasitic reactions during both cycling and storage lead to irreversible capacity loss. Understanding these degradation pathways is essential for developing mitigation strategies and improving battery reliability.Expand Specific Solutions04 Advanced characterization and testing methods for AZIBs

Sophisticated characterization techniques are employed to evaluate the cycle and calendar life of AZIBs. In-situ and operando methods such as X-ray diffraction, electron microscopy, and spectroscopic techniques provide real-time insights into degradation processes. Accelerated aging protocols help predict long-term performance under various conditions. Post-mortem analysis identifies failure mechanisms after cycling or storage. These advanced testing methodologies enable researchers to correlate battery performance with structural and chemical changes, facilitating the development of more durable zinc-ion battery systems.Expand Specific Solutions05 Novel cell designs and system-level approaches for reliability

Innovative cell architectures and system-level engineering can significantly enhance the reliability and longevity of AZIBs. Separator modifications prevent internal short circuits and dendrite penetration. Advanced current collectors with corrosion-resistant coatings maintain electrical contact throughout battery life. Battery management systems with specialized algorithms for zinc-ion chemistry optimize charging protocols and monitor state-of-health. These design approaches, combined with thermal management strategies, effectively address system-level failure modes and extend both cycle and calendar life of aqueous zinc-ion batteries.Expand Specific Solutions

Key Industry Players in AZIB Research and Manufacturing

The Aqueous Zinc-Ion Battery (AZIB) market is currently in an early growth phase, characterized by intensive research and development activities. The global market size for AZIBs is projected to expand significantly as energy storage demands increase, though it remains smaller than traditional lithium-ion technologies. Technical University of Denmark, Dalian Institute of Chemical Physics, and Shenzhen University are leading academic research on cycle life improvements, while companies like Shenzhen Hanshu Technology and Ruihai Bo Energy Technology are working to commercialize these advances. The technology maturity is moderate, with significant progress in understanding failure modes, but challenges remain in extending calendar life and improving cycling stability. Collaborative efforts between academic institutions and industry players are accelerating the development of more durable and efficient AZIB systems for practical applications.

Dalian Institute of Chemical Physics Chinese Academy of Sci

Technical Solution: Dalian Institute of Chemical Physics (DICP) has developed advanced zinc-based battery systems with focus on improving cycle life through novel electrolyte formulations. Their research includes using high-concentration electrolytes with zinc salts and specific additives to suppress dendrite formation and side reactions. DICP has pioneered the use of water-in-salt electrolytes that create a stable solid electrolyte interphase (SEI) on zinc anodes, significantly extending cycle life beyond 1000 cycles. Their calendar life improvements involve specialized passivation layers that prevent self-discharge and corrosion during idle periods. For failure mode analysis, DICP employs in-situ characterization techniques including X-ray diffraction and scanning electron microscopy to monitor structural changes during cycling, identifying key degradation mechanisms such as electrolyte decomposition, zinc dendrite formation, and cathode material dissolution.

Strengths: Superior electrolyte formulation expertise that effectively addresses zinc dendrite formation; comprehensive in-situ characterization capabilities for real-time failure analysis; strong integration of computational modeling with experimental validation. Weaknesses: Some solutions may involve expensive materials that limit commercial viability; water-in-salt electrolytes can face challenges in low-temperature environments.

Guangdong University of Technology

Technical Solution: Guangdong University of Technology has developed innovative approaches to enhance AZIB (Aqueous Zinc-Ion Battery) performance through electrode material engineering and electrolyte optimization. Their research team has created hierarchical porous cathode structures that accommodate volume changes during zinc ion insertion/extraction, significantly improving cycle stability. They've pioneered the use of nitrogen-doped carbon matrices to host active materials, which enhances electronic conductivity and provides buffer spaces for structural stability during cycling. For calendar life extension, they've developed specialized electrolyte additives that form protective films on electrode surfaces, preventing side reactions during storage periods. Their failure mode research utilizes advanced characterization techniques including operando synchrotron X-ray analysis and cryogenic electron microscopy to identify degradation mechanisms at atomic and molecular levels, particularly focusing on the correlation between zinc dendrite growth patterns and electrolyte composition.

Strengths: Excellent materials science approach with innovative electrode architectures; comprehensive understanding of interface chemistry between electrolyte and electrodes; strong capabilities in advanced characterization techniques. Weaknesses: Some solutions may be difficult to scale up for mass production; research primarily focuses on laboratory-scale cells rather than practical battery systems with commercial relevance.

Critical Failure Mechanisms Analysis in AZIBs

battery

PatentWO2025114546A1

Innovation

- The development of an aqueous zinc-ion battery with a thick manganese oxide-carbon composite cathode and a zinc powder-carbon composite anode, along with a thin solid zinc ion separator to suppress dendrite growth. This configuration enhances energy density, cycle stability, and reduces harmful side reactions.

Environmental Impact and Sustainability of AZIBs

The environmental impact of Aqueous Zinc-Ion Batteries (AZIBs) represents a critical consideration in their development and deployment. Unlike conventional lithium-ion batteries that contain toxic and flammable components, AZIBs utilize water-based electrolytes and abundant zinc materials, significantly reducing environmental hazards during production, operation, and disposal phases.

The sustainability profile of AZIBs is closely linked to their cycle life and failure modes. Research indicates that extended cycle life directly correlates with reduced environmental footprint, as fewer replacement batteries are required over time. Current generation AZIBs demonstrate promising sustainability metrics, with some advanced prototypes achieving over 10,000 cycles under optimal conditions, substantially outperforming many conventional battery technologies.

Material sourcing for AZIBs presents another environmental advantage. Zinc is approximately 1,000 times more abundant in the Earth's crust than lithium, with established global mining and recycling infrastructure. This abundance translates to reduced extraction impacts and lower energy requirements in the supply chain. Additionally, the manganese dioxide commonly used as cathode material is environmentally benign and widely available.

End-of-life management of AZIBs demonstrates favorable characteristics compared to conventional batteries. The non-toxic nature of most AZIB components facilitates safer disposal protocols. Furthermore, the recyclability of zinc components reaches up to 95% efficiency in current recycling systems, creating potential for closed-loop material cycles that minimize waste generation and resource depletion.

Carbon footprint analyses of AZIBs reveal promising results, with lifecycle assessments indicating approximately 60-70% lower greenhouse gas emissions compared to equivalent lithium-ion systems. This reduction stems primarily from simplified manufacturing processes, reduced energy-intensive purification requirements, and the elimination of organic solvents in electrolyte production.

Water consumption remains a consideration for AZIBs, as their aqueous nature requires careful management of water resources during manufacturing. However, research into electrolyte recycling and water reclamation systems shows potential for reducing freshwater demands by up to 80% in next-generation production facilities.

The correlation between failure modes and environmental impact deserves particular attention. Dendrite formation and electrode degradation not only limit battery performance but also potentially reduce recyclability of components. Addressing these failure mechanisms through advanced materials and design approaches therefore serves both performance and sustainability objectives simultaneously.

The sustainability profile of AZIBs is closely linked to their cycle life and failure modes. Research indicates that extended cycle life directly correlates with reduced environmental footprint, as fewer replacement batteries are required over time. Current generation AZIBs demonstrate promising sustainability metrics, with some advanced prototypes achieving over 10,000 cycles under optimal conditions, substantially outperforming many conventional battery technologies.

Material sourcing for AZIBs presents another environmental advantage. Zinc is approximately 1,000 times more abundant in the Earth's crust than lithium, with established global mining and recycling infrastructure. This abundance translates to reduced extraction impacts and lower energy requirements in the supply chain. Additionally, the manganese dioxide commonly used as cathode material is environmentally benign and widely available.

End-of-life management of AZIBs demonstrates favorable characteristics compared to conventional batteries. The non-toxic nature of most AZIB components facilitates safer disposal protocols. Furthermore, the recyclability of zinc components reaches up to 95% efficiency in current recycling systems, creating potential for closed-loop material cycles that minimize waste generation and resource depletion.

Carbon footprint analyses of AZIBs reveal promising results, with lifecycle assessments indicating approximately 60-70% lower greenhouse gas emissions compared to equivalent lithium-ion systems. This reduction stems primarily from simplified manufacturing processes, reduced energy-intensive purification requirements, and the elimination of organic solvents in electrolyte production.

Water consumption remains a consideration for AZIBs, as their aqueous nature requires careful management of water resources during manufacturing. However, research into electrolyte recycling and water reclamation systems shows potential for reducing freshwater demands by up to 80% in next-generation production facilities.

The correlation between failure modes and environmental impact deserves particular attention. Dendrite formation and electrode degradation not only limit battery performance but also potentially reduce recyclability of components. Addressing these failure mechanisms through advanced materials and design approaches therefore serves both performance and sustainability objectives simultaneously.

Standardization and Testing Protocols for AZIBs

The standardization of testing protocols for Aqueous Zinc-Ion Batteries (AZIBs) remains a critical challenge in the field, hampering direct comparison of research results and slowing commercial development. Currently, testing conditions vary significantly across research groups, with inconsistencies in parameters such as current density, voltage windows, electrolyte concentrations, and temperature conditions. These variations make it difficult to accurately assess and compare cycle life, calendar life, and failure modes across different studies.

To address these challenges, several standardization efforts have emerged in recent years. The Battery Testing Manual for AZIBs, developed through collaborative efforts between academic institutions and industry partners, proposes standardized protocols for evaluating key performance metrics. These protocols specify testing conditions including temperature ranges (typically 0-60°C), current densities (0.1C-10C), and depth of discharge parameters that enable meaningful comparisons across different AZIB chemistries.

For cycle life assessment, the protocols recommend full charge-discharge cycling at multiple C-rates, with specific attention to capacity retention benchmarks at 500, 1000, and 2000 cycles. Calendar life testing requires storage at various state-of-charge levels (0%, 50%, and 100%) under controlled temperature conditions, with periodic capacity measurements to track degradation rates. These standardized approaches help quantify the self-discharge characteristics unique to zinc-based systems.

Failure mode analysis protocols have been developed to systematically identify and categorize degradation mechanisms in AZIBs. These include post-mortem analysis techniques such as X-ray diffraction (XRD), scanning electron microscopy (SEM), and electrochemical impedance spectroscopy (EIS) performed at specific cycle intervals. The protocols detail sample preparation methods that preserve electrode integrity and prevent contamination, ensuring reliable analysis of zinc dendrite formation, cathode dissolution, and electrolyte degradation.

International standards organizations, including ISO and IEC, have begun incorporating AZIB-specific testing guidelines into their battery testing frameworks. These efforts aim to establish universally accepted testing methodologies that account for the unique characteristics of zinc-ion chemistry, such as dendrite formation propensity and pH sensitivity. The emerging standards specify reporting requirements that mandate disclosure of all testing conditions and cell components to ensure reproducibility.

Accelerated testing protocols have also been developed to predict long-term performance within reasonable timeframes. These methods employ elevated temperatures, increased cycling rates, and expanded voltage windows to induce accelerated aging, with mathematical models correlating accelerated test results to real-world performance expectations. Such approaches are particularly valuable for calendar life predictions, which otherwise would require years of testing.

To address these challenges, several standardization efforts have emerged in recent years. The Battery Testing Manual for AZIBs, developed through collaborative efforts between academic institutions and industry partners, proposes standardized protocols for evaluating key performance metrics. These protocols specify testing conditions including temperature ranges (typically 0-60°C), current densities (0.1C-10C), and depth of discharge parameters that enable meaningful comparisons across different AZIB chemistries.

For cycle life assessment, the protocols recommend full charge-discharge cycling at multiple C-rates, with specific attention to capacity retention benchmarks at 500, 1000, and 2000 cycles. Calendar life testing requires storage at various state-of-charge levels (0%, 50%, and 100%) under controlled temperature conditions, with periodic capacity measurements to track degradation rates. These standardized approaches help quantify the self-discharge characteristics unique to zinc-based systems.

Failure mode analysis protocols have been developed to systematically identify and categorize degradation mechanisms in AZIBs. These include post-mortem analysis techniques such as X-ray diffraction (XRD), scanning electron microscopy (SEM), and electrochemical impedance spectroscopy (EIS) performed at specific cycle intervals. The protocols detail sample preparation methods that preserve electrode integrity and prevent contamination, ensuring reliable analysis of zinc dendrite formation, cathode dissolution, and electrolyte degradation.

International standards organizations, including ISO and IEC, have begun incorporating AZIB-specific testing guidelines into their battery testing frameworks. These efforts aim to establish universally accepted testing methodologies that account for the unique characteristics of zinc-ion chemistry, such as dendrite formation propensity and pH sensitivity. The emerging standards specify reporting requirements that mandate disclosure of all testing conditions and cell components to ensure reproducibility.

Accelerated testing protocols have also been developed to predict long-term performance within reasonable timeframes. These methods employ elevated temperatures, increased cycling rates, and expanded voltage windows to induce accelerated aging, with mathematical models correlating accelerated test results to real-world performance expectations. Such approaches are particularly valuable for calendar life predictions, which otherwise would require years of testing.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!