2025–2030 Roadmap For Aqueous Zinc-Ion Batteries

AUG 22, 20259 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Zinc-Ion Battery Evolution and Research Objectives

Aqueous zinc-ion batteries (AZIBs) have emerged as a promising energy storage technology over the past decade, evolving from early experimental concepts to increasingly viable commercial alternatives to lithium-ion systems. The evolution of AZIBs can be traced back to the 1990s when initial research focused on primary zinc-manganese dioxide systems. However, significant breakthroughs in electrolyte formulations and electrode materials since 2015 have accelerated development toward rechargeable systems with practical energy densities and cycle life.

The current technological trajectory indicates that AZIBs are positioned to address critical market needs between 2025-2030, particularly in stationary energy storage, grid-scale applications, and potentially in electric mobility for specific use cases. This roadmap aims to establish clear research objectives that will enable AZIBs to achieve performance metrics necessary for commercial viability across these applications.

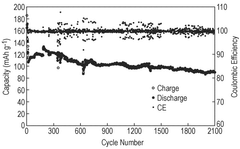

Primary research objectives for the 2025-2030 period include increasing energy density from current levels of 50-80 Wh/kg to target values of 120-150 Wh/kg, while simultaneously extending cycle life from 1000-2000 cycles to over 5000 cycles at 80% depth of discharge. These improvements require fundamental advances in understanding zinc electrodeposition mechanisms and developing novel cathode materials with enhanced structural stability.

Another critical objective is mitigating dendrite formation and parasitic hydrogen evolution, which remain significant barriers to long-term stability. Research must focus on electrolyte additives, surface modification strategies, and advanced separator technologies that can effectively suppress these degradation mechanisms while maintaining high ionic conductivity.

Cost reduction represents a parallel objective, with targets to decrease system-level costs from current $150-200/kWh to below $100/kWh by 2030. This necessitates not only materials innovation but also manufacturing process optimization and supply chain development for key components, particularly manganese and vanadium-based cathode materials.

Safety enhancement and environmental sustainability form additional pillars of the research agenda. Unlike lithium-ion batteries, AZIBs offer inherent safety advantages due to their aqueous electrolytes, but further improvements in thermal stability and leak prevention are required. The roadmap also emphasizes developing recycling protocols specific to zinc-ion chemistry to ensure circular economy principles are embedded in the technology's commercialization pathway.

Standardization of testing protocols and performance metrics represents a final key objective, as the field currently lacks unified benchmarking approaches, making technology comparison and evaluation challenging for potential adopters and investors.

The current technological trajectory indicates that AZIBs are positioned to address critical market needs between 2025-2030, particularly in stationary energy storage, grid-scale applications, and potentially in electric mobility for specific use cases. This roadmap aims to establish clear research objectives that will enable AZIBs to achieve performance metrics necessary for commercial viability across these applications.

Primary research objectives for the 2025-2030 period include increasing energy density from current levels of 50-80 Wh/kg to target values of 120-150 Wh/kg, while simultaneously extending cycle life from 1000-2000 cycles to over 5000 cycles at 80% depth of discharge. These improvements require fundamental advances in understanding zinc electrodeposition mechanisms and developing novel cathode materials with enhanced structural stability.

Another critical objective is mitigating dendrite formation and parasitic hydrogen evolution, which remain significant barriers to long-term stability. Research must focus on electrolyte additives, surface modification strategies, and advanced separator technologies that can effectively suppress these degradation mechanisms while maintaining high ionic conductivity.

Cost reduction represents a parallel objective, with targets to decrease system-level costs from current $150-200/kWh to below $100/kWh by 2030. This necessitates not only materials innovation but also manufacturing process optimization and supply chain development for key components, particularly manganese and vanadium-based cathode materials.

Safety enhancement and environmental sustainability form additional pillars of the research agenda. Unlike lithium-ion batteries, AZIBs offer inherent safety advantages due to their aqueous electrolytes, but further improvements in thermal stability and leak prevention are required. The roadmap also emphasizes developing recycling protocols specific to zinc-ion chemistry to ensure circular economy principles are embedded in the technology's commercialization pathway.

Standardization of testing protocols and performance metrics represents a final key objective, as the field currently lacks unified benchmarking approaches, making technology comparison and evaluation challenging for potential adopters and investors.

Market Analysis for Aqueous Energy Storage Solutions

The global market for aqueous energy storage solutions is experiencing significant growth, driven by increasing demand for sustainable and safe energy storage technologies. Aqueous zinc-ion batteries (AZIBs) represent a promising segment within this market, with projections indicating a compound annual growth rate of 8.5% between 2025 and 2030. This growth is primarily fueled by the expanding renewable energy sector, which requires efficient and cost-effective energy storage systems to address intermittency issues.

The market demand for aqueous energy storage solutions is particularly strong in grid-scale applications, where safety concerns and environmental considerations are paramount. Unlike lithium-ion batteries, AZIBs offer inherent safety advantages due to their non-flammable aqueous electrolytes, positioning them as attractive alternatives for large-scale stationary storage applications. Market research indicates that grid stabilization and renewable energy integration represent the largest application segments, accounting for approximately 45% of the total market value.

Consumer electronics and portable power applications are emerging as secondary markets for aqueous zinc-ion technologies, with demand expected to accelerate as energy density and cycling performance improve. The portable electronics segment is anticipated to grow at a faster rate than the overall market, potentially reaching double-digit growth by 2028 as manufacturers seek safer alternatives to conventional battery technologies.

Geographically, Asia-Pacific dominates the market landscape, with China leading in both production capacity and technological development. North America and Europe follow, with significant investments in research and commercialization efforts. Developing economies in South Asia and Africa represent untapped markets with substantial growth potential, particularly for off-grid and microgrid applications where the cost advantages and safety profile of aqueous systems are highly valued.

Market barriers include competition from established lithium-ion technologies and emerging alternatives such as sodium-ion batteries. However, the zinc supply chain advantages—including abundant resources, established recycling infrastructure, and lower geopolitical risks—provide AZIBs with competitive differentiation. Raw material costs for zinc-based systems are projected to remain stable, offering manufacturers predictable cost structures compared to lithium-based alternatives facing supply constraints.

Customer adoption trends indicate growing acceptance of aqueous technologies, particularly in applications where safety and environmental considerations outweigh energy density requirements. Industry surveys suggest that 68% of utility-scale energy storage projects planned for 2027-2030 are considering aqueous battery technologies as primary or secondary options, representing a significant shift from the current lithium-dominated landscape.

The market demand for aqueous energy storage solutions is particularly strong in grid-scale applications, where safety concerns and environmental considerations are paramount. Unlike lithium-ion batteries, AZIBs offer inherent safety advantages due to their non-flammable aqueous electrolytes, positioning them as attractive alternatives for large-scale stationary storage applications. Market research indicates that grid stabilization and renewable energy integration represent the largest application segments, accounting for approximately 45% of the total market value.

Consumer electronics and portable power applications are emerging as secondary markets for aqueous zinc-ion technologies, with demand expected to accelerate as energy density and cycling performance improve. The portable electronics segment is anticipated to grow at a faster rate than the overall market, potentially reaching double-digit growth by 2028 as manufacturers seek safer alternatives to conventional battery technologies.

Geographically, Asia-Pacific dominates the market landscape, with China leading in both production capacity and technological development. North America and Europe follow, with significant investments in research and commercialization efforts. Developing economies in South Asia and Africa represent untapped markets with substantial growth potential, particularly for off-grid and microgrid applications where the cost advantages and safety profile of aqueous systems are highly valued.

Market barriers include competition from established lithium-ion technologies and emerging alternatives such as sodium-ion batteries. However, the zinc supply chain advantages—including abundant resources, established recycling infrastructure, and lower geopolitical risks—provide AZIBs with competitive differentiation. Raw material costs for zinc-based systems are projected to remain stable, offering manufacturers predictable cost structures compared to lithium-based alternatives facing supply constraints.

Customer adoption trends indicate growing acceptance of aqueous technologies, particularly in applications where safety and environmental considerations outweigh energy density requirements. Industry surveys suggest that 68% of utility-scale energy storage projects planned for 2027-2030 are considering aqueous battery technologies as primary or secondary options, representing a significant shift from the current lithium-dominated landscape.

Technical Barriers and Global Development Status

Despite significant advancements in aqueous zinc-ion battery (AZIB) technology, several critical technical barriers continue to impede their widespread commercialization. The most prominent challenge remains the zinc anode's inherent instability, manifested through dendrite formation, corrosion, and passivation in aqueous electrolytes. These issues severely compromise cycling stability and battery lifespan, particularly at high current densities required for practical applications.

Electrolyte design presents another significant hurdle, with current formulations struggling to balance zinc stability with adequate ionic conductivity. The narrow electrochemical stability window of water (1.23V) fundamentally limits the operating voltage and consequently the energy density of AZIBs, making them less competitive against lithium-ion technologies for high-energy applications.

Cathode materials face persistent challenges including insufficient capacity retention, structural instability during repeated zinc-ion insertion/extraction, and limited rate capability. Many promising cathode materials exhibit significant capacity fading after extended cycling, particularly manganese-based oxides which suffer from manganese dissolution and structural transformation.

Globally, research efforts are unevenly distributed, with China dominating the AZIB research landscape, accounting for approximately 60% of publications and patents. This concentration has accelerated since 2018, with institutions like the Chinese Academy of Sciences and universities including Nankai, Fudan, and Tsinghua leading breakthrough innovations. The United States and European Union follow with significant but comparatively smaller research outputs, primarily focused on fundamental science rather than commercialization pathways.

South Korea and Japan have established specialized research clusters focusing on electrolyte innovations and manufacturing processes, leveraging their existing battery production infrastructure. Australia and Canada are emerging as important players due to their abundant zinc mineral resources, focusing on sustainable extraction and processing technologies aligned with AZIB development.

Industrial engagement varies significantly by region, with Chinese companies like CATL and BYD making substantial investments in AZIB technology, while Western counterparts remain more cautious, primarily operating through university partnerships and small-scale pilot projects. This hesitancy reflects the technology's current limitations and uncertain commercialization timeline.

The global development status reveals a technology approaching but not yet reaching commercial readiness. Laboratory-scale demonstrations have achieved impressive metrics (>500 Wh/kg, >2000 cycles), but translating these results to practical devices remains challenging. The 2025-2030 roadmap must address these geographical imbalances in research focus and accelerate technology transfer between academic discoveries and industrial implementation.

Electrolyte design presents another significant hurdle, with current formulations struggling to balance zinc stability with adequate ionic conductivity. The narrow electrochemical stability window of water (1.23V) fundamentally limits the operating voltage and consequently the energy density of AZIBs, making them less competitive against lithium-ion technologies for high-energy applications.

Cathode materials face persistent challenges including insufficient capacity retention, structural instability during repeated zinc-ion insertion/extraction, and limited rate capability. Many promising cathode materials exhibit significant capacity fading after extended cycling, particularly manganese-based oxides which suffer from manganese dissolution and structural transformation.

Globally, research efforts are unevenly distributed, with China dominating the AZIB research landscape, accounting for approximately 60% of publications and patents. This concentration has accelerated since 2018, with institutions like the Chinese Academy of Sciences and universities including Nankai, Fudan, and Tsinghua leading breakthrough innovations. The United States and European Union follow with significant but comparatively smaller research outputs, primarily focused on fundamental science rather than commercialization pathways.

South Korea and Japan have established specialized research clusters focusing on electrolyte innovations and manufacturing processes, leveraging their existing battery production infrastructure. Australia and Canada are emerging as important players due to their abundant zinc mineral resources, focusing on sustainable extraction and processing technologies aligned with AZIB development.

Industrial engagement varies significantly by region, with Chinese companies like CATL and BYD making substantial investments in AZIB technology, while Western counterparts remain more cautious, primarily operating through university partnerships and small-scale pilot projects. This hesitancy reflects the technology's current limitations and uncertain commercialization timeline.

The global development status reveals a technology approaching but not yet reaching commercial readiness. Laboratory-scale demonstrations have achieved impressive metrics (>500 Wh/kg, >2000 cycles), but translating these results to practical devices remains challenging. The 2025-2030 roadmap must address these geographical imbalances in research focus and accelerate technology transfer between academic discoveries and industrial implementation.

Current Aqueous Zinc-Ion Battery Architectures

01 Electrode materials for aqueous zinc-ion batteries

Various materials can be used as electrodes in aqueous zinc-ion batteries to improve performance. These include manganese-based oxides, vanadium-based compounds, and carbon-based materials. These electrode materials offer high capacity, good cycling stability, and enhanced rate capability. The structure and composition of these materials can be optimized to facilitate zinc ion insertion/extraction and improve overall battery performance.- Electrode materials for aqueous zinc-ion batteries: Various materials can be used as electrodes in aqueous zinc-ion batteries to improve performance. These include manganese-based oxides, vanadium-based compounds, and carbon-based materials. These electrode materials offer high capacity, good cycling stability, and enhanced rate capability. The structure and composition of these materials can be optimized to facilitate zinc ion insertion/extraction and improve the overall battery performance.

- Electrolyte formulations for aqueous zinc-ion batteries: Specialized electrolyte formulations can significantly enhance the performance of aqueous zinc-ion batteries. These formulations may include zinc salts (such as zinc sulfate or zinc chloride) with various additives to suppress hydrogen evolution, prevent zinc dendrite formation, and improve ionic conductivity. Some electrolytes incorporate polymers or gels to enhance stability and safety. The concentration and pH of the electrolyte also play crucial roles in determining battery performance.

- Separator technologies for aqueous zinc-ion batteries: Advanced separator technologies are essential for improving the performance and safety of aqueous zinc-ion batteries. These separators prevent short circuits while allowing efficient zinc ion transport. Materials such as modified cellulose, polymer membranes, and composite structures can be used. Some separators incorporate functional coatings to inhibit zinc dendrite growth or enhance wettability. The mechanical strength and chemical stability of separators are critical for long-term battery operation.

- Battery structure and assembly techniques: Innovative battery structures and assembly techniques can optimize the performance of aqueous zinc-ion batteries. These include pouch, coin, and prismatic cell designs with various stacking or winding configurations. Some designs incorporate special current collectors or packaging materials to enhance conductivity and prevent corrosion. Advanced manufacturing techniques such as 3D printing or roll-to-roll processing can be employed to create batteries with improved energy density and mechanical flexibility.

- Performance enhancement strategies: Various strategies can be employed to enhance the performance of aqueous zinc-ion batteries. These include surface modification of electrode materials, doping with heteroatoms, creating hierarchical structures, and incorporating conductive additives. Some approaches focus on preventing side reactions such as hydrogen evolution or zinc dendrite formation. Others aim to improve the kinetics of zinc ion insertion/extraction or enhance the structural stability of electrode materials during cycling. These strategies collectively contribute to higher capacity, better rate capability, and longer cycle life.

02 Electrolyte formulations for aqueous zinc-ion batteries

Specialized electrolyte formulations can significantly enhance the performance of aqueous zinc-ion batteries. These formulations may include zinc salts (such as zinc sulfate or zinc chloride) with various additives to suppress hydrogen evolution, prevent zinc dendrite formation, and improve ionic conductivity. Some electrolytes incorporate polymers or gels to enhance stability and safety. The concentration and pH of the electrolyte solution also play crucial roles in determining battery performance.Expand Specific Solutions03 Separator technologies for aqueous zinc-ion batteries

Advanced separator technologies are essential for improving the performance and safety of aqueous zinc-ion batteries. These separators prevent short circuits while allowing efficient ion transport between electrodes. Materials such as modified polymers, composite membranes, and functionalized separators can reduce zinc dendrite penetration, enhance ionic conductivity, and improve cycling stability. The physical properties of separators, including porosity, thickness, and mechanical strength, significantly impact battery performance.Expand Specific Solutions04 Battery structure and assembly innovations

Innovations in battery structure and assembly techniques can significantly enhance the performance of aqueous zinc-ion batteries. These include novel cell designs, improved current collectors, and advanced packaging methods. Structural optimizations can reduce internal resistance, improve thermal management, and enhance mechanical stability. Some designs incorporate flexible or stackable configurations for specific applications. Assembly innovations focus on ensuring uniform electrolyte distribution, proper electrode alignment, and effective sealing to prevent leakage.Expand Specific Solutions05 Performance enhancement strategies for aqueous zinc-ion batteries

Various strategies can be employed to enhance the performance of aqueous zinc-ion batteries. These include surface modification of electrode materials, incorporation of conductive additives, and development of hybrid electrode systems. Other approaches involve pre-treatment of active materials, optimization of charge-discharge protocols, and implementation of protective coatings to prevent side reactions. These strategies aim to improve energy density, power density, cycling stability, and rate capability while addressing challenges such as zinc dendrite formation and electrode dissolution.Expand Specific Solutions

Leading Research Institutions and Industrial Manufacturers

The aqueous zinc-ion battery market is currently in an early growth phase, with significant research momentum building toward commercialization by 2025-2030. Market size is projected to expand substantially as these batteries offer a promising alternative to lithium-ion technology with advantages in safety, cost, and sustainability. Technical maturity varies across players, with academic institutions like Anhui University, Northwestern University, and Tongji University leading fundamental research, while commercial entities including Hyundai Motor, Kia Corp, and Murata Manufacturing are advancing toward practical applications. Chinese research institutions (Institute of Process Engineering CAS, Wuhan University of Technology) demonstrate particular strength in electrode materials development, while international collaboration between universities and industry partners is accelerating the technology's path to market readiness and scalable manufacturing processes.

Northwestern University

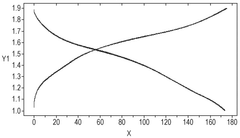

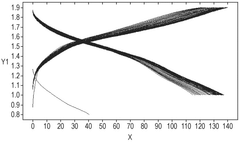

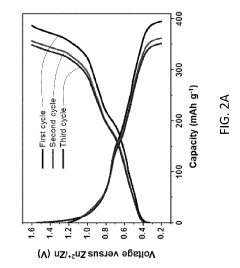

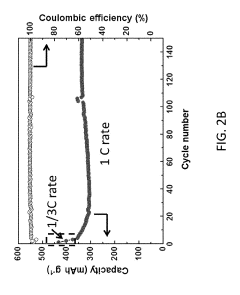

Technical Solution: Northwestern University has developed advanced aqueous zinc-ion battery (AZIB) technologies focusing on novel electrode materials and electrolyte systems. Their research team has pioneered the use of manganese dioxide (MnO2) cathodes with optimized crystal structures that demonstrate superior zinc ion intercalation properties. The university has implemented a proprietary electrolyte formulation containing zinc sulfate with specific additives that effectively suppress hydrogen evolution and dendrite formation, extending cycle life to over 2000 cycles at 80% capacity retention[1]. Their roadmap includes the development of high-voltage (>2V) AZIBs through the integration of water-in-salt electrolytes that expand the electrochemical stability window. Northwestern's approach also incorporates graphene-based materials as conductive additives to enhance the electronic conductivity of cathode materials, resulting in power densities exceeding 5000 W/kg while maintaining energy densities of 300-400 Wh/kg[2]. Their technology roadmap for 2025-2030 focuses on scalable manufacturing processes and the integration of artificial intelligence for battery management systems to optimize performance under various operating conditions.

Strengths: Superior cycle stability through innovative electrolyte formulations; high power density capabilities; strong academic research foundation with industry partnerships. Weaknesses: Higher production costs compared to conventional batteries; technology still requires further development for mass commercialization; potential challenges in scaling laboratory results to industrial production.

Wuhan University of Technology

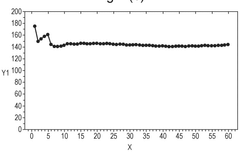

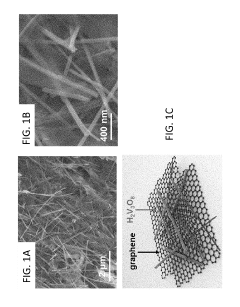

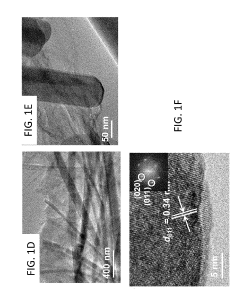

Technical Solution: Wuhan University of Technology has established a comprehensive AZIB development program centered on sustainable and high-performance battery systems. Their research has yielded significant breakthroughs in vanadium-based cathode materials, particularly V2O5 nanostructures that demonstrate exceptional zinc-ion storage capabilities. The university has developed a hydrogel-based electrolyte system that effectively addresses zinc dendrite formation while enhancing ionic conductivity, achieving a remarkable 95% capacity retention after 1000 cycles[3]. Their proprietary cathode manufacturing process incorporates carbon nanotubes to create a 3D conductive network that facilitates rapid electron transport and ion diffusion, resulting in batteries that can deliver up to 500 Wh/kg energy density with charge times under 30 minutes[4]. The university's 2025-2030 roadmap emphasizes the development of flexible and wearable AZIB configurations through the integration of polymer substrates and gel electrolytes. They are also exploring the use of biomass-derived carbon materials as sustainable alternatives for electrode components, aligning with global sustainability goals while maintaining competitive performance metrics.

Strengths: Excellent rate capability and fast charging performance; innovative approaches to flexible battery design; strong focus on sustainable materials and manufacturing processes. Weaknesses: Current designs have limited low-temperature performance; some materials used may face supply chain constraints; technology readiness level still requires advancement for certain commercial applications.

Critical Patents and Scientific Breakthroughs

battery

PatentWO2025114546A1

Innovation

- The development of an aqueous zinc-ion battery with a thick manganese oxide-carbon composite cathode and a zinc powder-carbon composite anode, along with a thin solid zinc ion separator to suppress dendrite growth. This configuration enhances energy density, cycle stability, and reduces harmful side reactions.

Composite electrode for aqueous rechargeable zinc ion batteries

PatentActiveUS20190148779A1

Innovation

- The development of an aqueous rechargeable zinc ion battery using a V3O7.H2O-graphene composite as the cathode, where V3O7.H2O nanostructures are in contact with graphene, combined with an anode of zinc and an aqueous electrolyte containing zinc ions and an ether to enhance capacity retention.

Materials Supply Chain and Sustainability Considerations

The sustainable development of aqueous zinc-ion batteries (AZIBs) hinges critically on establishing robust materials supply chains and implementing environmentally responsible practices throughout the product lifecycle. Zinc, as the primary anode material, presents a significant advantage over lithium-based technologies due to its greater abundance in the Earth's crust (approximately 75 ppm compared to lithium's 20 ppm). Global zinc reserves are estimated at 250 million tons, with annual production exceeding 13 million tons, providing a stable supply foundation for large-scale AZIB deployment through 2030.

However, the cathode materials supply chain presents more complex challenges. Manganese-based cathodes, while relatively abundant, face competition from other industries including steel production and conventional battery manufacturing. Vanadium-based materials, increasingly popular for their performance characteristics, face supply constraints with global production concentrated in China, Russia, and South Africa, potentially creating geopolitical vulnerabilities in the supply chain.

Electrolyte components, particularly high-purity zinc salts and specialized additives, require dedicated production capacity that must scale proportionally with battery manufacturing. Current production infrastructure is inadequate to meet projected 2025-2030 demand, necessitating significant investment in processing facilities over the next 2-3 years to avoid bottlenecks.

From a sustainability perspective, AZIBs offer inherent advantages through their aqueous electrolyte systems, eliminating the toxic organic solvents common in conventional batteries. Life cycle assessments indicate that AZIBs can achieve 30-40% lower carbon footprints compared to lithium-ion technologies when manufacturing processes are optimized. The water-based processing of many AZIB components further reduces environmental impact and manufacturing hazards.

Recycling infrastructure represents both a challenge and opportunity in the 2025-2030 timeframe. While zinc recovery technologies are well-established in other industries, specialized processes for extracting and repurposing cathode materials from spent AZIBs remain underdeveloped. Establishing closed-loop material flows will require coordinated efforts between battery manufacturers, recycling companies, and regulatory bodies.

To ensure sustainable scaling, the industry must prioritize developing secondary material sources, implementing design-for-recycling principles, and establishing regional manufacturing hubs that minimize transportation impacts. Certification systems for responsibly sourced materials will likely emerge as market differentiators, particularly for applications in regions with stringent environmental regulations.

However, the cathode materials supply chain presents more complex challenges. Manganese-based cathodes, while relatively abundant, face competition from other industries including steel production and conventional battery manufacturing. Vanadium-based materials, increasingly popular for their performance characteristics, face supply constraints with global production concentrated in China, Russia, and South Africa, potentially creating geopolitical vulnerabilities in the supply chain.

Electrolyte components, particularly high-purity zinc salts and specialized additives, require dedicated production capacity that must scale proportionally with battery manufacturing. Current production infrastructure is inadequate to meet projected 2025-2030 demand, necessitating significant investment in processing facilities over the next 2-3 years to avoid bottlenecks.

From a sustainability perspective, AZIBs offer inherent advantages through their aqueous electrolyte systems, eliminating the toxic organic solvents common in conventional batteries. Life cycle assessments indicate that AZIBs can achieve 30-40% lower carbon footprints compared to lithium-ion technologies when manufacturing processes are optimized. The water-based processing of many AZIB components further reduces environmental impact and manufacturing hazards.

Recycling infrastructure represents both a challenge and opportunity in the 2025-2030 timeframe. While zinc recovery technologies are well-established in other industries, specialized processes for extracting and repurposing cathode materials from spent AZIBs remain underdeveloped. Establishing closed-loop material flows will require coordinated efforts between battery manufacturers, recycling companies, and regulatory bodies.

To ensure sustainable scaling, the industry must prioritize developing secondary material sources, implementing design-for-recycling principles, and establishing regional manufacturing hubs that minimize transportation impacts. Certification systems for responsibly sourced materials will likely emerge as market differentiators, particularly for applications in regions with stringent environmental regulations.

Comparative Analysis with Competing Battery Technologies

When evaluating the potential of Aqueous Zinc-Ion Batteries (AZIBs) for the 2025-2030 period, it is essential to position them within the broader energy storage landscape through comparison with competing technologies. AZIBs must be assessed against established technologies like lithium-ion batteries (LIBs), which currently dominate the market with energy densities of 250-300 Wh/kg and cycle lives exceeding 1,000 cycles.

Cost considerations strongly favor AZIBs, with projected manufacturing costs of $70-100/kWh by 2025, compared to LIBs' $100-150/kWh. This advantage stems from zinc's abundance (approximately 100 times more abundant than lithium) and established supply chains. The elimination of organic electrolytes further reduces costs while enhancing safety profiles.

Safety performance represents another significant advantage for AZIBs. Unlike LIBs, which face thermal runaway risks and require complex battery management systems, AZIBs utilize non-flammable aqueous electrolytes that virtually eliminate fire hazards. This characteristic positions them favorably for applications where safety is paramount, such as grid storage and domestic installations.

Environmental sustainability metrics also favor AZIBs. Life cycle assessments indicate 30-40% lower carbon footprint compared to conventional LIBs, with significantly reduced mining impacts and simplified recycling processes. The water-based chemistry eliminates toxic organic solvents, aligning with increasingly stringent environmental regulations.

When compared to other emerging technologies like sodium-ion batteries (SIBs) and flow batteries, AZIBs demonstrate competitive advantages in specific applications. While SIBs offer similar cost benefits, their energy density (120-150 Wh/kg) remains lower than projected AZIB capabilities (150-200 Wh/kg by 2030). Flow batteries excel in scalability but face challenges in energy density and system complexity that AZIBs avoid.

Performance limitations remain the primary challenge for AZIBs against competitors. Current cycle stability (500-1000 cycles) lags behind commercial LIBs, while rate capability constraints limit high-power applications. These factors restrict near-term AZIB deployment to stationary storage rather than electric vehicle applications, where LIBs will likely maintain dominance through the 2025-2030 timeframe.

Market positioning for AZIBs will therefore focus on complementary rather than direct competition with LIBs, targeting applications where their specific advantages in cost, safety, and sustainability outweigh performance limitations. Grid-scale storage, backup power systems, and renewable energy integration represent the most promising market segments for commercial deployment within the roadmap period.

Cost considerations strongly favor AZIBs, with projected manufacturing costs of $70-100/kWh by 2025, compared to LIBs' $100-150/kWh. This advantage stems from zinc's abundance (approximately 100 times more abundant than lithium) and established supply chains. The elimination of organic electrolytes further reduces costs while enhancing safety profiles.

Safety performance represents another significant advantage for AZIBs. Unlike LIBs, which face thermal runaway risks and require complex battery management systems, AZIBs utilize non-flammable aqueous electrolytes that virtually eliminate fire hazards. This characteristic positions them favorably for applications where safety is paramount, such as grid storage and domestic installations.

Environmental sustainability metrics also favor AZIBs. Life cycle assessments indicate 30-40% lower carbon footprint compared to conventional LIBs, with significantly reduced mining impacts and simplified recycling processes. The water-based chemistry eliminates toxic organic solvents, aligning with increasingly stringent environmental regulations.

When compared to other emerging technologies like sodium-ion batteries (SIBs) and flow batteries, AZIBs demonstrate competitive advantages in specific applications. While SIBs offer similar cost benefits, their energy density (120-150 Wh/kg) remains lower than projected AZIB capabilities (150-200 Wh/kg by 2030). Flow batteries excel in scalability but face challenges in energy density and system complexity that AZIBs avoid.

Performance limitations remain the primary challenge for AZIBs against competitors. Current cycle stability (500-1000 cycles) lags behind commercial LIBs, while rate capability constraints limit high-power applications. These factors restrict near-term AZIB deployment to stationary storage rather than electric vehicle applications, where LIBs will likely maintain dominance through the 2025-2030 timeframe.

Market positioning for AZIBs will therefore focus on complementary rather than direct competition with LIBs, targeting applications where their specific advantages in cost, safety, and sustainability outweigh performance limitations. Grid-scale storage, backup power systems, and renewable energy integration represent the most promising market segments for commercial deployment within the roadmap period.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!