Advanced Materials And Coatings For Improving Turbine Engines Performance

SEP 23, 20254 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engines Advanced Materials Background

The primary objective of this research is to explore advanced materials and coatings that can enhance the performance and durability of turbine engines. Turbine engines operate under extreme conditions, including high temperatures, pressures, and corrosive environments, which can lead to material degradation and reduced efficiency over time.

This section aims to provide a comprehensive overview of the current state of materials and coatings used in turbine engines, identifying the challenges and limitations faced by existing solutions. It will also highlight the key properties and characteristics required for advanced materials and coatings to address these challenges, such as high-temperature resistance, oxidation resistance, thermal barrier capabilities, and improved thermal conductivity.

This section aims to provide a comprehensive overview of the current state of materials and coatings used in turbine engines, identifying the challenges and limitations faced by existing solutions. It will also highlight the key properties and characteristics required for advanced materials and coatings to address these challenges, such as high-temperature resistance, oxidation resistance, thermal barrier capabilities, and improved thermal conductivity.

Turbine Engines Coatings Market Analysis

- Market Overview

The market for advanced materials and coatings for turbine engines is driven by the need for improved efficiency, durability, and performance in the aerospace and power generation industries. - Market Segmentation

The market can be segmented based on material type (ceramics, metals, composites), coating type (thermal barrier, oxidation resistant, abrasion resistant), application (aircraft engines, industrial gas turbines, power generation turbines), and geography. - Market Drivers

- Stringent emission regulations

- Demand for fuel-efficient engines

- Increasing air traffic and power generation needs

- Market Restraints

- High cost of advanced materials and coatings

- Lengthy certification processes for aerospace applications

- Market Trends

- Development of new high-temperature resistant materials

- Adoption of additive manufacturing for complex component production

- Integration of sensors and smart coatings for condition monitoring

- Market Forecast

The market for advanced turbine engine coatings is expected to grow at a significant rate due to increasing demand for fuel-efficient and high-performance engines in the aerospace and power generation sectors.

Current Turbine Engines Materials Challenges

- Thermal Barrier Coatings

Thermal barrier coatings (TBCs) protect turbine components from high temperatures, improving engine efficiency and durability. However, current TBCs have limited thermal cycling resistance and susceptibility to erosion and oxidation. - Superalloy Degradation

Nickel-based superalloys used in turbine blades and vanes experience creep, fatigue, and oxidation at high temperatures, leading to premature failure and reduced service life. - Environmental Degradation

Turbine components are exposed to harsh environments, including high temperatures, corrosive gases, and particulate matter, which can cause erosion, corrosion, and fouling, reducing performance and reliability. - Cooling System Limitations

Current cooling systems for turbine components have limitations in terms of efficiency and effectiveness, leading to higher operating temperatures and increased material degradation.

Existing Turbine Engines Coatings Solutions

01 Turbine engine performance optimization

Techniques like improving combustion efficiency, reducing aerodynamic losses, and enhancing cooling systems to increase power output, fuel efficiency, and overall engine performance.- Turbine engine performance optimization: Techniques to enhance turbine engine performance, including improving combustion efficiency, reducing aerodynamic losses, and enhancing cooling systems, aimed at increasing power output, fuel efficiency, and overall performance.

- Turbine blade design and materials: Optimized blade shapes, advanced materials like ceramics and composites, and cooling techniques to improve aerodynamic efficiency, durability, and heat resistance of turbine blades.

- Combustion system improvements: Advancements in fuel injection methods, combustor designs, and emission control technologies to enhance combustion efficiency, reduce emissions, and improve overall engine performance.

- Turbine engine control and monitoring: Advanced control systems, sensor networks, and data analytics for real-time optimization, condition monitoring, and predictive maintenance of turbine engines.

- Turbine engine component design and materials: Design and materials for components like compressors, combustors, and turbines to impact performance characteristics such as efficiency, durability, and weight.

02 Turbine blade design and materials

Advancements in blade geometry, coatings, and use of advanced materials like ceramics and composites to improve aerodynamic efficiency, durability, and heat resistance.Expand Specific Solutions03 Combustion system improvements

Enhancements in fuel injection techniques, combustor design, and air-fuel mixing for more efficient and cleaner combustion, resulting in improved engine performance and reduced emissions.Expand Specific Solutions04 Turbine cooling and thermal management

Advanced cooling techniques like film cooling and impingement cooling to mitigate thermal stresses and improve engine durability by effective cooling and thermal management.Expand Specific Solutions05 Turbine engine control and monitoring systems

Advanced control and monitoring systems to optimize turbine engine performance by monitoring parameters like temperature, pressure, and vibration, and adjusting engine settings accordingly.Expand Specific Solutions

Key Turbine Engines Materials Players

The advanced materials and coatings for improving turbine engine performance is a mature technology field with a large market size. The key players are well-established companies like United Technologies Corp., Honeywell, General Electric, and Safran, as well as emerging players like XiAn Xinyao Ceramic Composite Materials Co. Ltd., Bgrimm Technology Group Co. Ltd., and various universities and research institutes.

United Technologies Corp.

Technical Solution: United Technologies Corp. has developed ceramic matrix composites (CMCs) and thermal barrier coatings (TBCs) for turbine engines, offering higher temperature capabilities, improved durability, and enhanced thermal insulation.

Strengths: Extensive experience, strong R&D capabilities. Weaknesses: Limited portfolio beyond aerospace.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed thermal barrier coatings, abradable coatings, and single-crystal superalloys for turbine engines, improving efficiency, durability, and high-temperature strength.

Strengths: Broad portfolio, strong R&D. Weaknesses: Limited focus on CMCs.

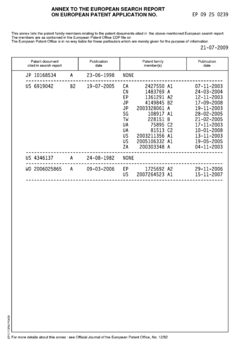

Turbine Engines Advanced Materials Patents

Economic oxidation and fatigue resistant metallic coating

PatentActiveEP2145969A1

Innovation

- The coating combines various elements like cobalt, chromium, aluminum, yttrium, hafnium, silicon, zirconium, and molybdenum to provide improved oxidation and fatigue resistance.

- The coating reduces the thermal expansion mismatch between the coating and the turbine alloy, minimizing fatigue performance issues.

- The coating is low-cost and can be used as a standalone bond coat or as part of a thermal barrier coating system.

Turbine Engines Materials Regulatory Landscape

The regulatory landscape for advanced materials and coatings used in turbine engines is complex and multifaceted. Stringent safety and environmental regulations govern the development, testing, and deployment of these materials. Regulatory bodies, such as aviation authorities and environmental agencies, play a crucial role in ensuring compliance with industry standards and emission norms.

Manufacturers must adhere to rigorous certification processes, which involve extensive testing and validation of material properties, durability, and performance under various operating conditions. Environmental regulations also mandate strict limits on emissions and the use of hazardous substances, driving the need for eco-friendly and sustainable material solutions.

Furthermore, intellectual property rights and patent landscapes significantly influence the competitive dynamics within the industry. Companies must navigate intricate patent portfolios and licensing agreements to access cutting-edge technologies while safeguarding their proprietary innovations. Collaborations and strategic partnerships between material suppliers, engine manufacturers, and research institutions are often necessary to navigate this complex regulatory and competitive landscape.

Manufacturers must adhere to rigorous certification processes, which involve extensive testing and validation of material properties, durability, and performance under various operating conditions. Environmental regulations also mandate strict limits on emissions and the use of hazardous substances, driving the need for eco-friendly and sustainable material solutions.

Furthermore, intellectual property rights and patent landscapes significantly influence the competitive dynamics within the industry. Companies must navigate intricate patent portfolios and licensing agreements to access cutting-edge technologies while safeguarding their proprietary innovations. Collaborations and strategic partnerships between material suppliers, engine manufacturers, and research institutions are often necessary to navigate this complex regulatory and competitive landscape.

Turbine Engines Materials Environmental Impact

Turbine engines are widely used in various industries, including aviation, power generation, and transportation. However, their operation can have significant environmental impacts, primarily due to emissions and resource consumption. The environmental impact of turbine engines can be categorized into several aspects:

Air Pollution: Turbine engines emit various pollutants, such as nitrogen oxides (NOx), carbon monoxide (CO), unburned hydrocarbons (UHC), and particulate matter (PM). These emissions contribute to air pollution, which can have adverse effects on human health and the environment. Stringent emission regulations have been implemented to mitigate these impacts.

Greenhouse Gas Emissions: The combustion of fossil fuels in turbine engines releases carbon dioxide (CO2), a major greenhouse gas contributing to climate change. The aviation industry, in particular, is a significant contributor to greenhouse gas emissions, and efforts are underway to develop more efficient engines and alternative fuels to reduce the carbon footprint.

Noise Pollution: Turbine engines can generate significant noise levels, particularly during takeoff and landing operations in the aviation industry. Noise pollution can have adverse effects on human health and wildlife, leading to the implementation of noise abatement procedures and the development of quieter engine technologies.

Air Pollution: Turbine engines emit various pollutants, such as nitrogen oxides (NOx), carbon monoxide (CO), unburned hydrocarbons (UHC), and particulate matter (PM). These emissions contribute to air pollution, which can have adverse effects on human health and the environment. Stringent emission regulations have been implemented to mitigate these impacts.

Greenhouse Gas Emissions: The combustion of fossil fuels in turbine engines releases carbon dioxide (CO2), a major greenhouse gas contributing to climate change. The aviation industry, in particular, is a significant contributor to greenhouse gas emissions, and efforts are underway to develop more efficient engines and alternative fuels to reduce the carbon footprint.

Noise Pollution: Turbine engines can generate significant noise levels, particularly during takeoff and landing operations in the aviation industry. Noise pollution can have adverse effects on human health and wildlife, leading to the implementation of noise abatement procedures and the development of quieter engine technologies.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!