Advanced Cooling Technologies For Turbine Engines

SEP 23, 20255 MIN READ

Generate Your Research Report Instantly with AI Agent

Patsnap Eureka helps you evaluate technical feasibility & market potential.

Turbine Engine Cooling Technology Background and Objectives

The primary objective of this research is to explore advanced cooling technologies for turbine engines, which play a crucial role in enhancing engine efficiency, durability, and overall performance. Turbine engines operate under extreme temperatures, and effective cooling systems are essential to prevent thermal degradation and ensure reliable operation.

This section will delve into the technological background and goals of advanced cooling technologies for turbine engines. It will provide a comprehensive overview of the historical development and evolution of cooling systems, highlighting the key milestones and breakthroughs that have shaped this field. Additionally, it will outline the specific technological objectives and targets that these advanced cooling technologies aim to achieve, such as higher heat dissipation rates, improved thermal management, and increased engine operating temperatures.

This section will delve into the technological background and goals of advanced cooling technologies for turbine engines. It will provide a comprehensive overview of the historical development and evolution of cooling systems, highlighting the key milestones and breakthroughs that have shaped this field. Additionally, it will outline the specific technological objectives and targets that these advanced cooling technologies aim to achieve, such as higher heat dissipation rates, improved thermal management, and increased engine operating temperatures.

Turbine Engine Cooling Market Demand Analysis

- Turbine Engine Cooling Market Overview The turbine engine cooling market is driven by the increasing demand for efficient and reliable cooling systems in aerospace, power generation, and industrial applications. As turbine engines operate at high temperatures, effective cooling is crucial for optimal performance and longevity.

- Market Drivers

- Rising demand for air travel and aircraft production

- Increasing focus on energy efficiency and emissions reduction

- Growth in the power generation sector, particularly gas turbines

- Market Segmentation

The market can be segmented based on:

- Application (aerospace, power generation, industrial)

- Cooling technology (air cooling, liquid cooling, hybrid cooling)

- Engine type (turbofan, turboprop, turboshaft)

- Regional Analysis

Major regions with significant market share include:

- North America (driven by aerospace and power generation industries)

- Europe (focus on energy efficiency and emissions reduction)

- Asia-Pacific (rapid industrialization and aircraft production)

- Market Trends

- Increasing adoption of advanced cooling technologies (e.g., microchannel cooling, transpiration cooling)

- Integration of cooling systems with engine health monitoring and prognostics

- Development of lightweight and compact cooling solutions

Current Turbine Engine Cooling Technology Status and Challenges

- Mature Cooling Technologies

Conventional air cooling and liquid cooling systems have been widely adopted in turbine engines, providing effective heat dissipation for critical components. - Thermal Barrier Coatings

Advanced ceramic coatings applied to turbine blades and combustion chambers offer enhanced thermal insulation, enabling higher operating temperatures. - Film Cooling

Injecting coolant air through small holes in turbine blades creates a protective film, shielding the surface from extreme temperatures. - Impingement Cooling

High-velocity coolant jets impinge on the inner surfaces of turbine components, providing efficient heat transfer and cooling.

- Key Challenges

- Achieving higher turbine inlet temperatures for improved efficiency while maintaining component integrity.

- Developing advanced materials and coatings capable of withstanding extreme thermal environments.

- Optimizing cooling system designs for maximum heat transfer and minimal aerodynamic losses.

State-of-the-Art Turbine Engine Cooling Solutions

01 Air Cooling Systems

Various air cooling systems, including impingement cooling, film cooling, and internal channels, are used to cool turbine components.- Blade and Vane Cooling: Internal cooling channels, film cooling holes, and thermal barrier coatings are used to cool turbine blades and vanes exposed to high temperatures.

- Casing and Shroud Cooling: Impingement cooling and thermal barrier coatings are employed to cool the turbine casing and shrouds surrounding the blades.

- Cooling Air Management: Efficient management and supply of cooling air, including bleeding from the compressor, using heat exchangers, and optimizing flow paths, are crucial.

- Disk and Shaft Cooling: Internal cooling channels, impingement cooling, and thermal barrier coatings are used to cool turbine disks and shafts.

- Advanced Cooling Technologies: Newer technologies like transpiration cooling, advanced materials, and coatings with improved thermal properties are being explored.

02 Thermal Barrier Coatings

Ceramic coatings are applied to turbine components to provide insulation and reduce heat transfer, allowing higher operating temperatures.Expand Specific Solutions03 Cooling Air Management

Techniques for optimizing cooling air distribution, flow paths, pressure, and temperature are employed for efficient cooling.Expand Specific Solutions04 Integrated Cooling and Sealing

Integrated systems combine cooling air delivery with sealing features to prevent hot gas ingestion and leakage.Expand Specific Solutions05 Advanced Cooling Techniques

Advanced ceramics, composites, cooling geometries, active cooling systems, and additive manufacturing are being explored for improved cooling.Expand Specific Solutions

Key Players in Turbine Engine Cooling Technology

The advanced cooling technologies for turbine engines market is growing, driven by increasing demand for efficient and high-performance turbine engines across various industries. Key players like United Technologies Corp., General Electric Company, Honeywell International Technologies Ltd., Pratt & Whitney Canada Corp., Rolls-Royce Plc, and AECC Commercial Aircraft Engine Co., Ltd. have made significant advancements, while academic institutions contribute to research and innovation.

General Electric Company

Technical Solution: GE has developed advanced cooling technologies utilizing advanced materials, coatings, and cooling designs for turbine blades and vanes, improving heat transfer and thermal barrier properties.

Strengths: Extensive experience, advanced materials expertise. Weaknesses: Proprietary technologies may limit adoption.

Honeywell International Technologies Ltd.

Technical Solution: Honeywell has developed advanced cooling technologies utilizing advanced materials, coatings, and cooling designs for turbine blades and vanes, offering integrated cooling solutions.

Strengths: Advanced materials and coatings expertise, integrated solutions. Weaknesses: Limited experience in some techniques.

Critical Turbine Engine Cooling Technology Insights

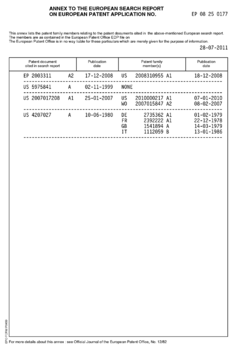

Vapour cooling system for a gas turbine engine

PatentInactiveEP1956214A3

Innovation

- The cooling system utilizes a vapor cooling assembly to transport thermal energy away from non-rotating components extending into the engine flowpath.

- The system aims to recover thermal energy transferred away from the gas flowpath, potentially improving overall engine efficiency.

- The cooling system targets non-rotating components, which may have different cooling requirements compared to rotating components.

Environmental Impact of Advanced Turbine Engine Cooling Technologies

Advanced turbine engine cooling technologies have a significant impact on the environment, primarily through their influence on emissions and fuel efficiency. Improved cooling systems enable higher operating temperatures, leading to increased thermal efficiency and reduced fuel consumption, which in turn lowers greenhouse gas emissions. However, certain cooling technologies may involve the use of hazardous materials or generate waste products that require proper disposal.

The environmental impact assessment should consider the entire lifecycle of the cooling technology, from material sourcing and manufacturing processes to operational emissions and end-of-life disposal. Quantitative analysis of factors such as carbon footprint, water usage, and waste generation is crucial for evaluating the overall environmental sustainability. Additionally, the potential for resource depletion and ecosystem disruption due to material extraction or waste disposal should be carefully examined.

Ultimately, the goal is to strike a balance between maximizing engine performance and minimizing environmental impact. Innovative cooling solutions that prioritize eco-friendly materials, closed-loop systems, and efficient waste management practices can contribute to a more sustainable aviation industry. Continuous research and development efforts are necessary to mitigate the environmental consequences of advanced turbine engine cooling technologies.

The environmental impact assessment should consider the entire lifecycle of the cooling technology, from material sourcing and manufacturing processes to operational emissions and end-of-life disposal. Quantitative analysis of factors such as carbon footprint, water usage, and waste generation is crucial for evaluating the overall environmental sustainability. Additionally, the potential for resource depletion and ecosystem disruption due to material extraction or waste disposal should be carefully examined.

Ultimately, the goal is to strike a balance between maximizing engine performance and minimizing environmental impact. Innovative cooling solutions that prioritize eco-friendly materials, closed-loop systems, and efficient waste management practices can contribute to a more sustainable aviation industry. Continuous research and development efforts are necessary to mitigate the environmental consequences of advanced turbine engine cooling technologies.

Regulatory Landscape for Turbine Engine Cooling Innovations

The regulatory landscape for turbine engine cooling innovations is a complex and ever-evolving field. Stringent emission standards and environmental regulations have driven the need for more efficient and sustainable cooling technologies. Governments and regulatory bodies worldwide have implemented strict guidelines to reduce the environmental impact of turbine engines, particularly in terms of greenhouse gas emissions and noise pollution.

Compliance with these regulations is crucial for turbine engine manufacturers and operators. Failure to meet the established standards can result in hefty fines, operational restrictions, or even the grounding of aircraft. As a result, the industry is under immense pressure to develop and adopt advanced cooling technologies that not only enhance engine performance but also minimize their environmental footprint.

Furthermore, the regulatory landscape extends beyond environmental concerns. Safety regulations play a pivotal role in governing the design and implementation of cooling systems. Rigorous testing and certification processes are in place to ensure the reliability and durability of these technologies, safeguarding the well-being of passengers and crew members. Continuous monitoring and adherence to these safety standards are essential for maintaining operational integrity and public trust in the aviation industry.

Compliance with these regulations is crucial for turbine engine manufacturers and operators. Failure to meet the established standards can result in hefty fines, operational restrictions, or even the grounding of aircraft. As a result, the industry is under immense pressure to develop and adopt advanced cooling technologies that not only enhance engine performance but also minimize their environmental footprint.

Furthermore, the regulatory landscape extends beyond environmental concerns. Safety regulations play a pivotal role in governing the design and implementation of cooling systems. Rigorous testing and certification processes are in place to ensure the reliability and durability of these technologies, safeguarding the well-being of passengers and crew members. Continuous monitoring and adherence to these safety standards are essential for maintaining operational integrity and public trust in the aviation industry.

Unlock deeper insights with Patsnap Eureka Quick Research — get a full tech report to explore trends and direct your research. Try now!

Generate Your Research Report Instantly with AI Agent

Supercharge your innovation with Patsnap Eureka AI Agent Platform!