Steering device

a steering device and telescopic technology, applied in the direction of steering parts, vehicle components, transportation and packaging, etc., can solve the problems of deteriorating assemblability of components, affecting the assemblability of components, so as to prevent the rotation of the inner pipe, improve the assemblability, and improve the assemblability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

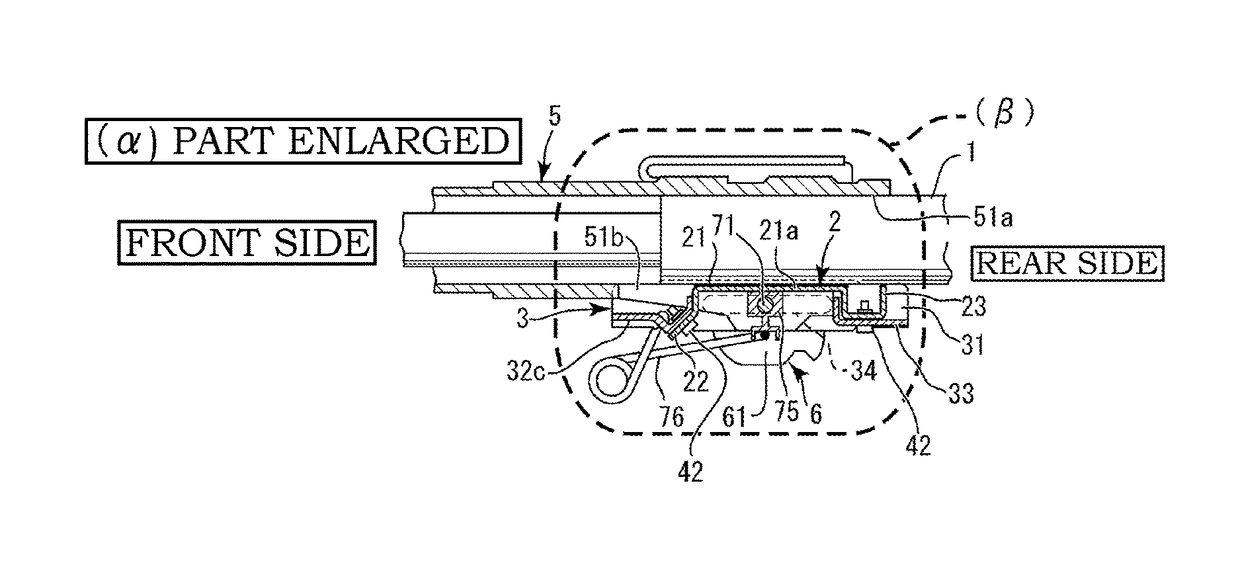

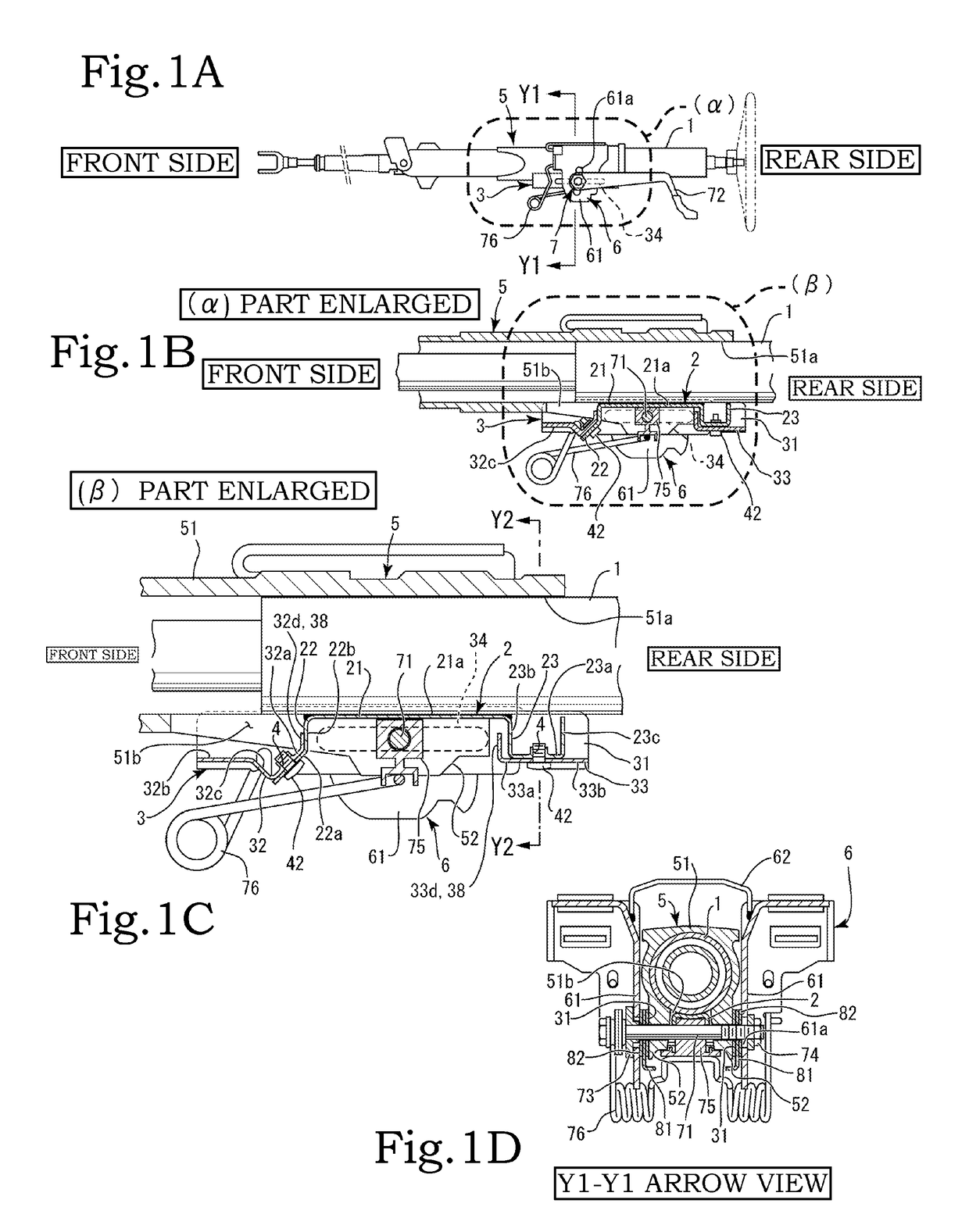

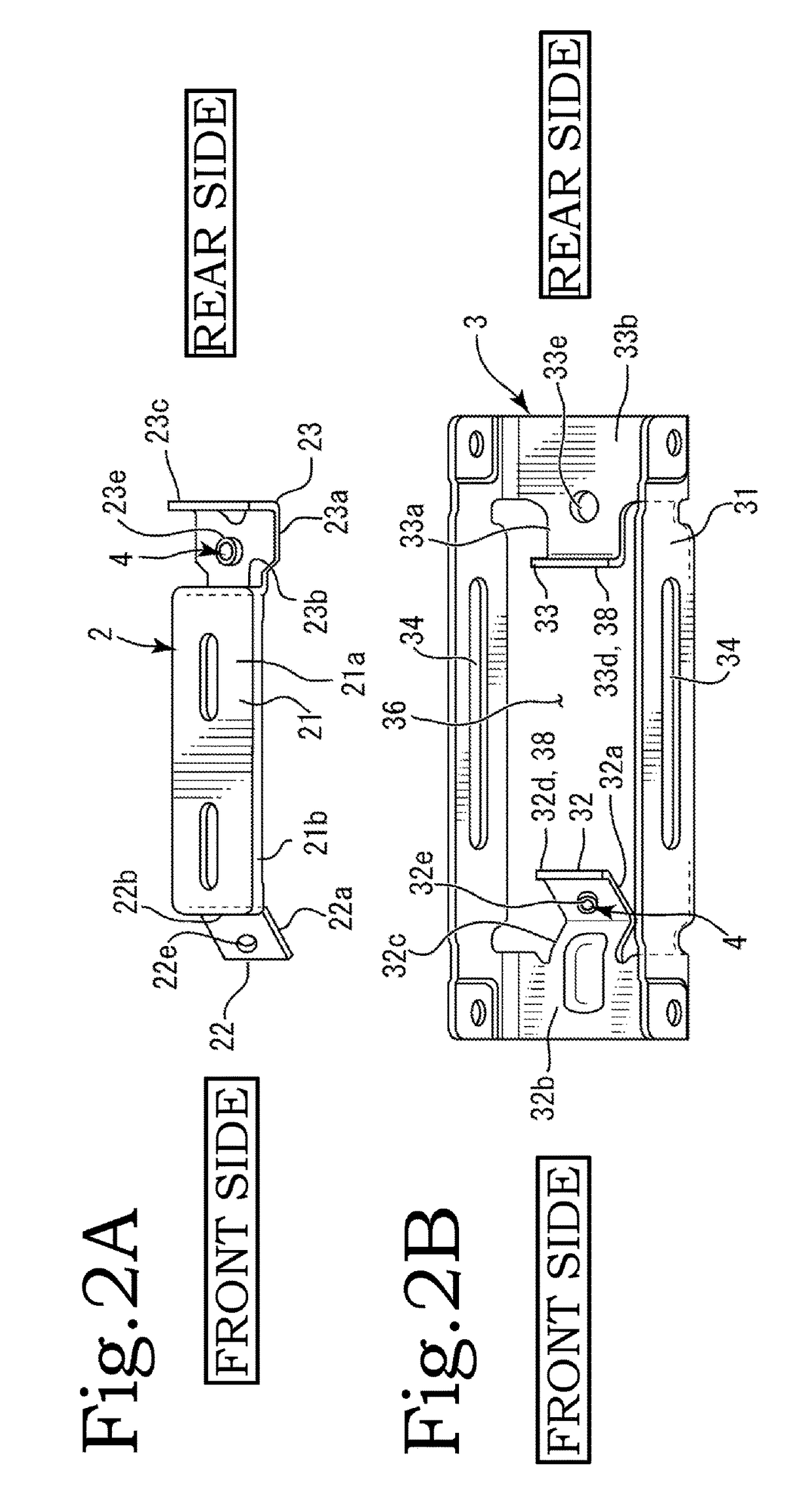

[0025]Embodiments of the present invention are explained below with reference to the drawings. As terms indicating directions in the explanation, there are a front side and a rear side. The front side and the rear side are based on the front-back direction of an automobile in a state in which a steering device in the present invention is mounted on the automobile. Specifically, in constituent members of the steering device, a front wheel side of the automobile is set as the front side and a steering wheel side is set as the rear side. The axial direction of shafts configuring the steering device is the same as the front-back direction. The front side and the rear side are described in main drawings.

[0026]The steering device in the present invention includes a tilting / telescopic mechanism. The main configuration of the steering device includes, as shown in FIGS. 1A to 1D, an inner pipe 1, a stopper bracket 2, a hanger bracket 3, screw sections 4, an outer column 5, a fixed bracket 6,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com