Golf bag able to be disassembled and assembled freely

a golf bag and disassembly technology, applied in the field of golf bags that can be disassembled and assembled freely, can solve the problems of multiple combination processes of traditional golf bags, difficult disassembly of these golf bags for the unprofessional, and loss of function of the hole of plastic parts, so as to avoid resource waste and easy change of cloth color

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

embodiment 1

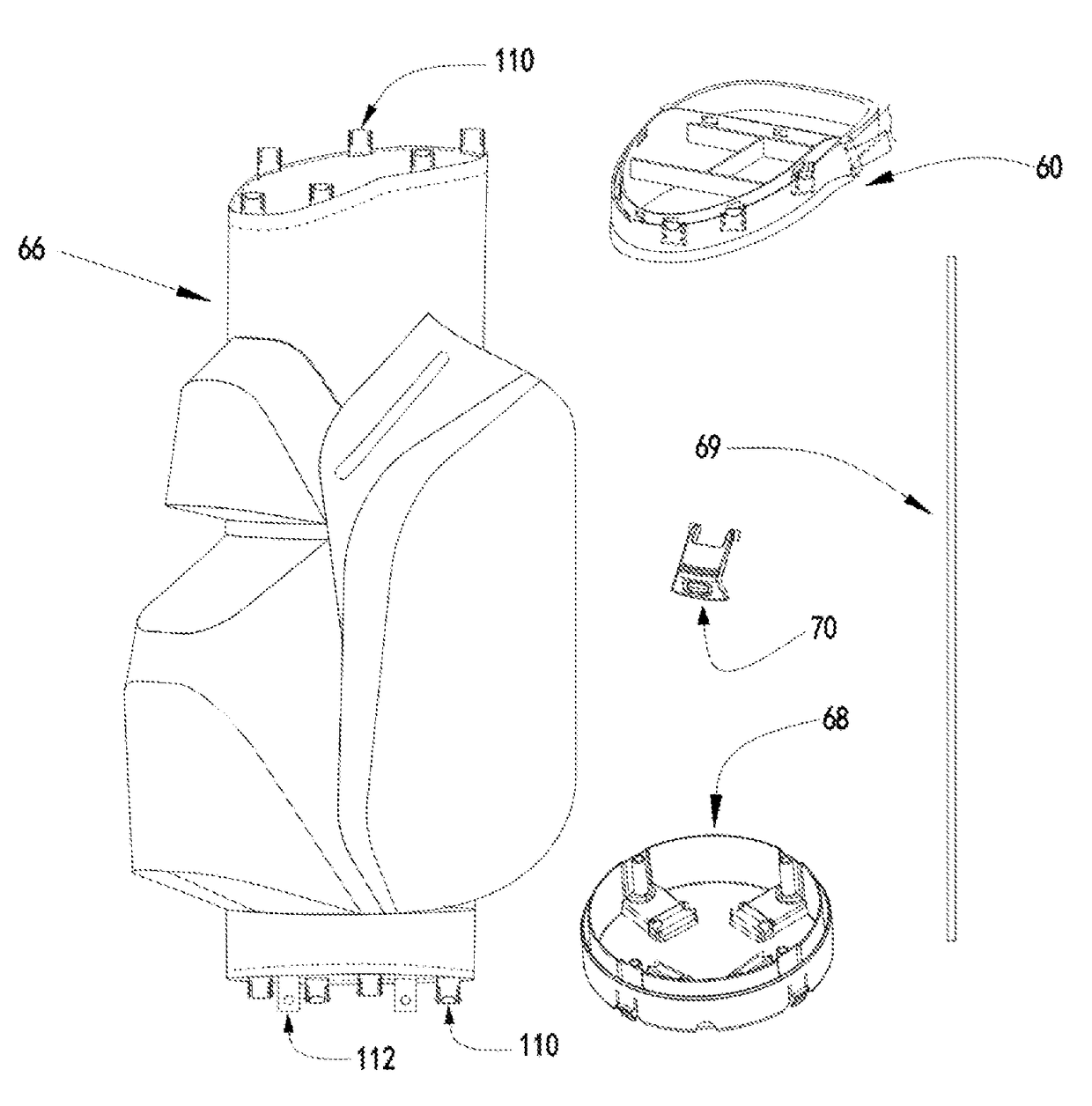

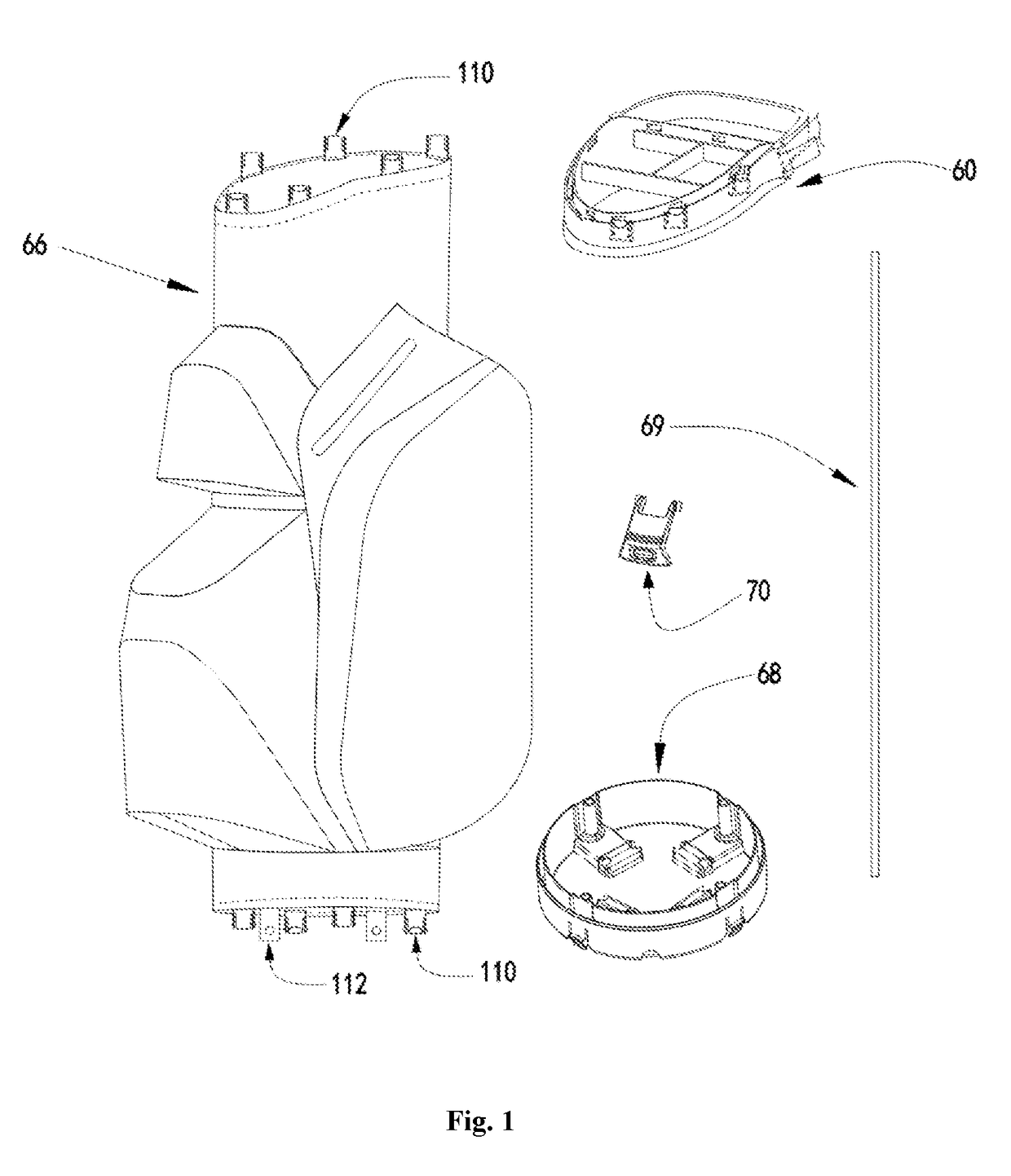

[0045]As FIG. 1 shown, the present invention is made up of a head frame 60, a bag body portion 66, a bottom frame 68, a supporting stick 69, a buckle pin 70, a buckle 110 and a cloth ear 112;

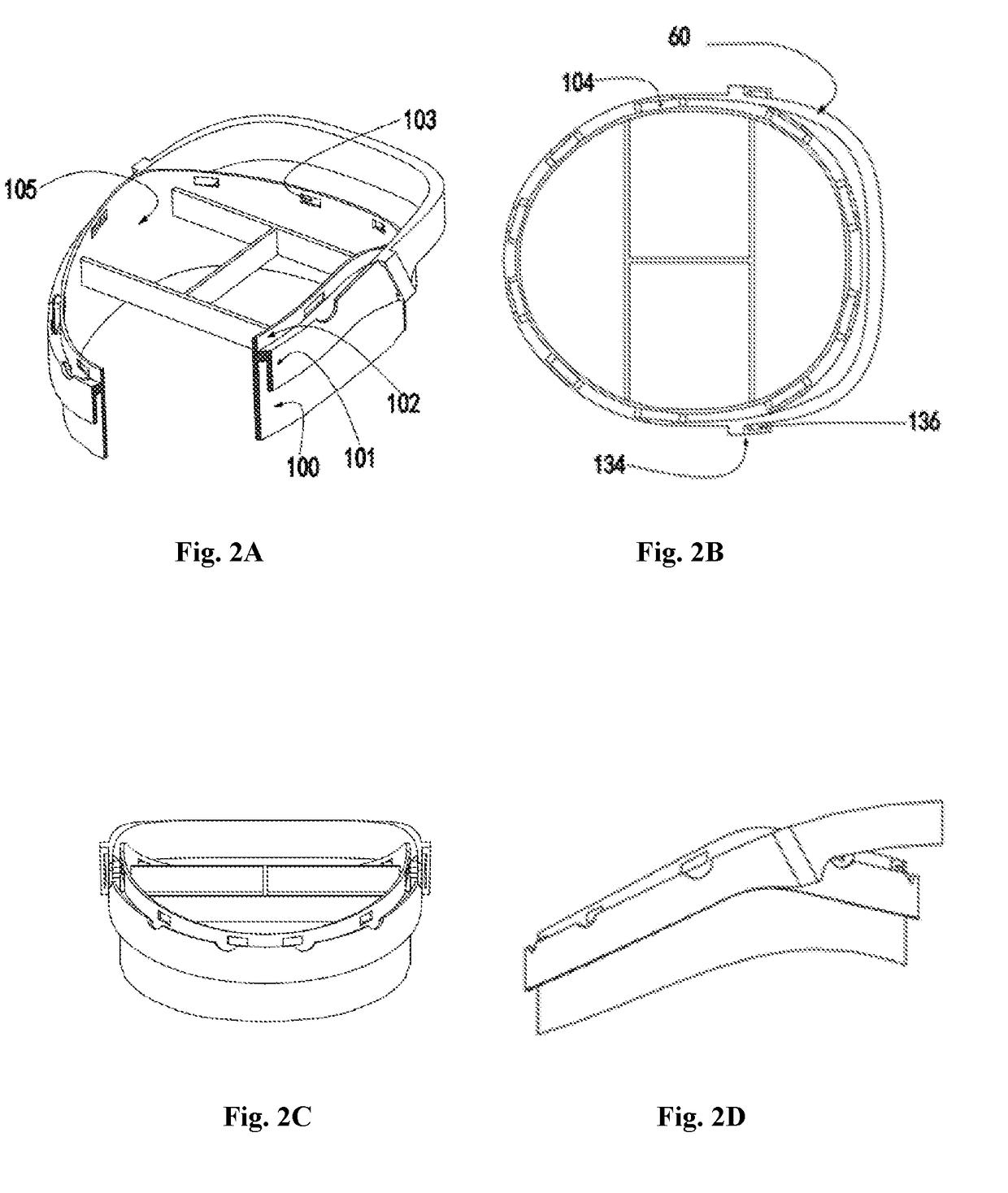

[0046]As shown in FIGS. 1, 2A, 2B, 2C, 2D and 5, a main wall 100, a reinforcing wall 101 located outside of the main wall, an upper end of the main wall 102 are respectively located on the head frame 60; a plurality of holes 103 are arranged on the upper end of the main wall 102, a plurality of buckle holes 104 are arranged between the upper end of the main wall 102 and the reinforcing wall 101, a buckle 110 of an upper end of a bag body portion 66 passes through the buckle hole 104 from bottom to top, a hook A is arranged on the buckle 110, the hook A is stuck in an upper edge of the reinforcing wall 101.

[0047]The buckle 110 and the bag body portion 66 are fixed by sewing; when the bag body portion 66 is combined with the head frame 60, a plurality of buckles 110 of the upper end of the bag bod...

embodiment 2

[0057]The difference with embodiment 1 is all cloth ears of the lower end of the bag body portion is replaced, only buckles are arranged for this golf bag able to be disassembled and assembled freely, as FIG. 12 shown, this golf bag is made up of a head frame 60, a bag body portion 66, a bottom frame 68, a supporting stick 69, a buckle pin 70 and a buckle 110.

[0058]As shown in FIGS. 2A, 2B, 2C, 2D, 5 and 12, a main wall 100, a reinforcing wall 101 located outside of the main wall, an upper end of the main wall 102 are respectively located on the head frame 60; a plurality of holes 103 are arranged on the upper end of the main wall 102, a plurality of buckle holes 104 are arranged between the upper end of the main wall 102 and the reinforcing wall 101, a buckle 110 of an upper end of a bag body portion 66 passes through the buckle hole 104 from bottom to top, a hook A is arranged on the buckle 110, the hook A is stuck in an upper edge of the reinforcing wall 101.

[0059]The buckle 110 ...

embodiment 3

[0068]Based on embodiment 1 and embodiment 2, the golf bag able to be disassembled and assembled freely can be used as a stand bag, as shown in FIGS. 14A, 14B and 15A, 15B and 15C, a foldable folding wall 137 is arranged on one end of the bottom frame 68, and two supporting legs 71 are attached to one end of the head frame, a supporting steel wire is arranged between the supporting legs and the bottom frame, by bending a thin wall 138 on the folding wall, two supporting legs 71 on the supporting steel wire can be opened freely, the supporting legs can be inclined landed and used as a stand, such that the bottom frame can be parallel landed.

[0069]The head frame 60 or the bottom frame 68 can be any shape, like circular, oval, rhombic and square shape.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com