Multi-thread chain stitch sewing machine with seam ravel preventing apparatus

a multi-thread, chain stitch technology, applied in sewing apparatus, needle severing devices, textiles and paper, etc., can solve the problems of unsolved improvement needs, excessive time-consuming, and seam ravel throughout the seam, so as to prevent the slippage of looper thread, less effort, and the effect of seam ravel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0067]An embodiment of the present invention is described below with reference to the accompanying drawings.

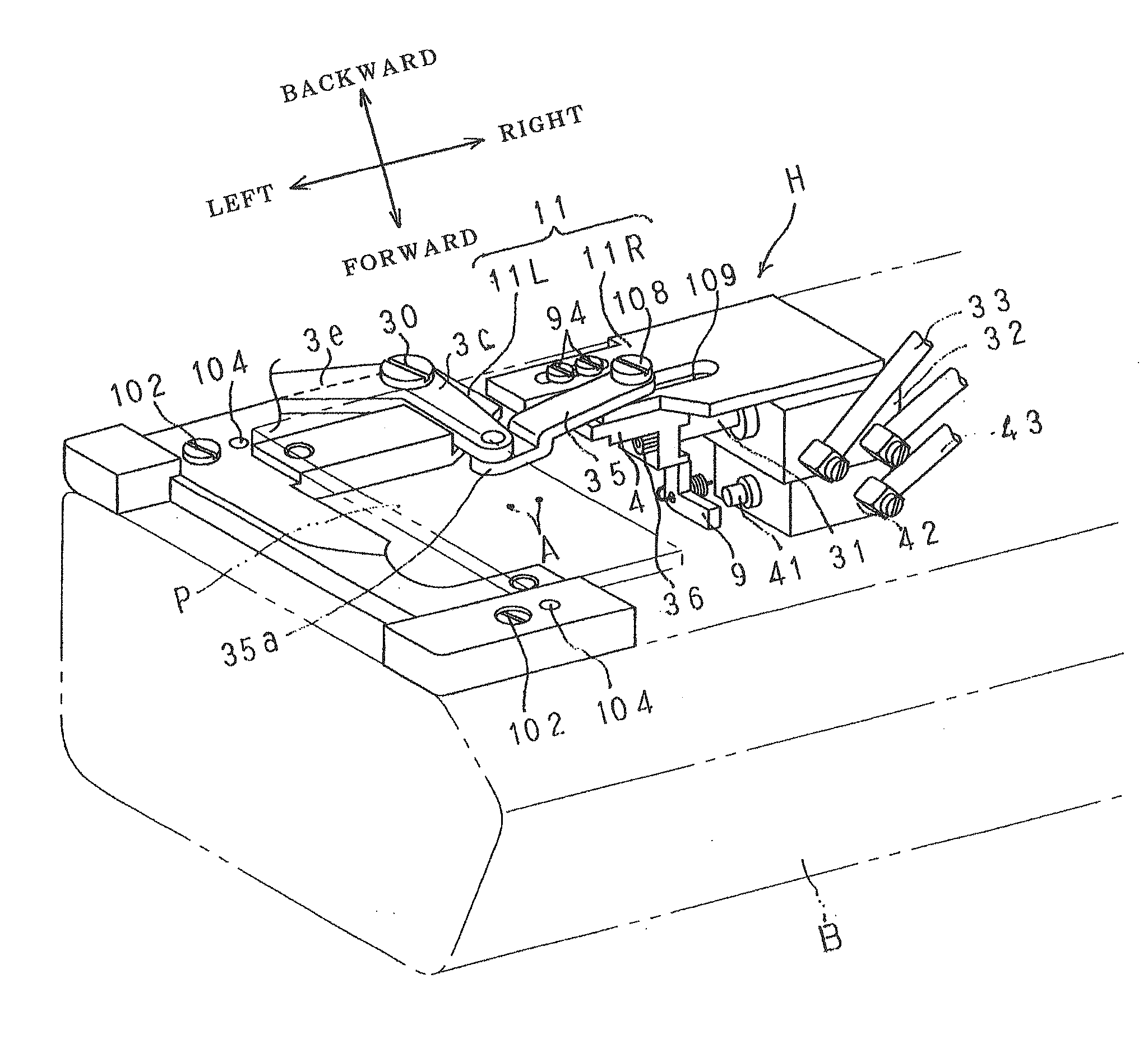

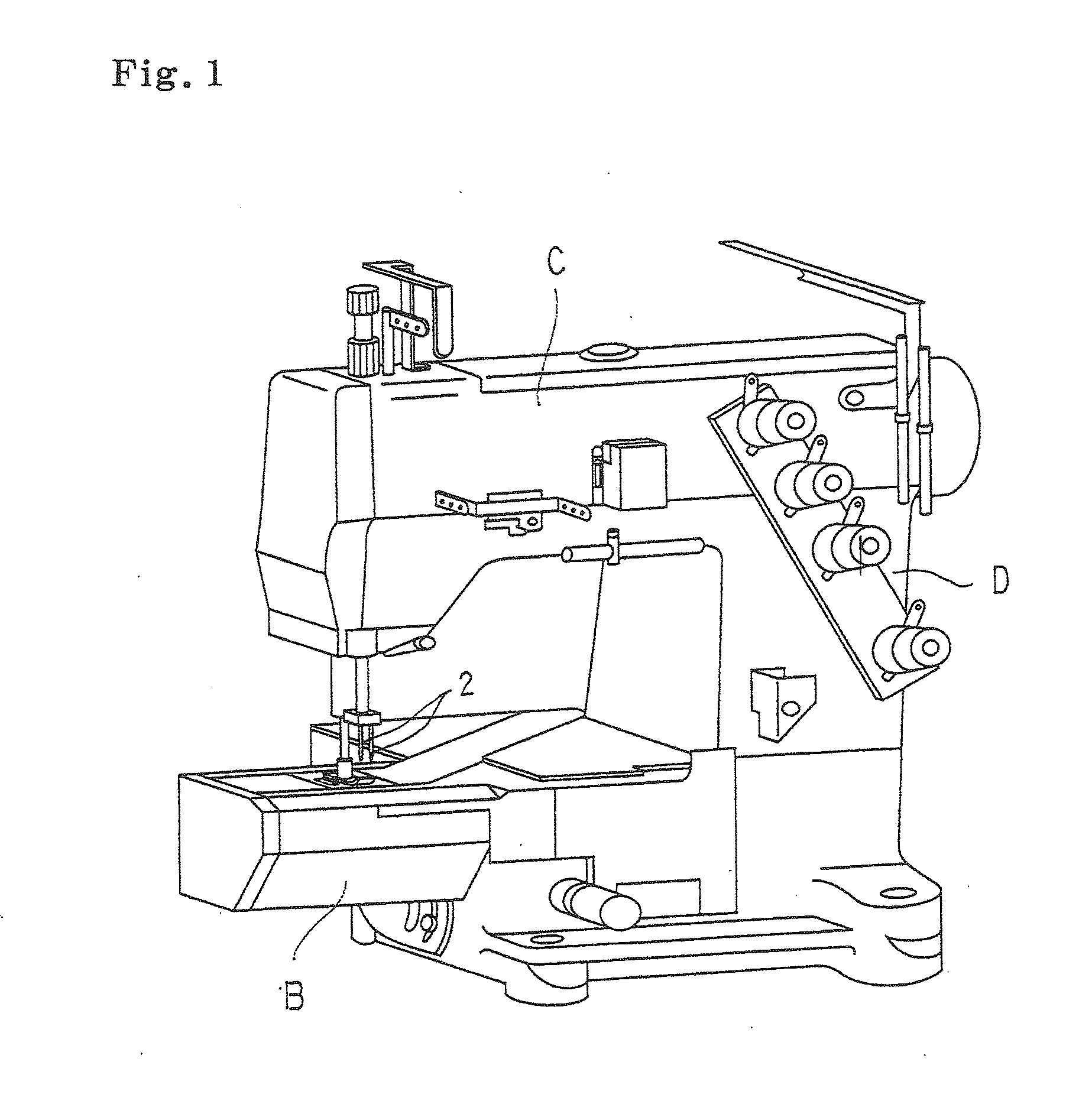

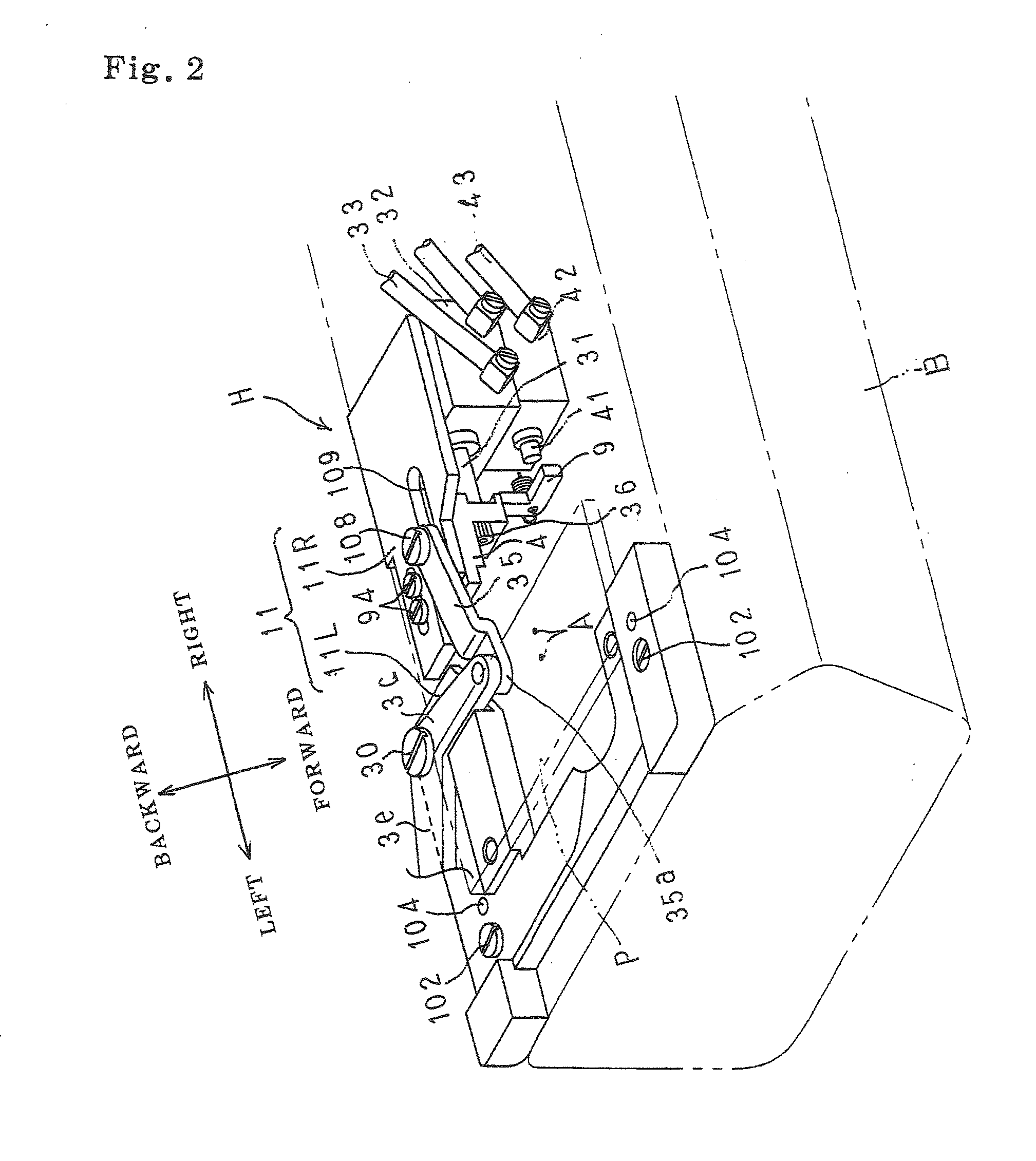

[0068]FIG. 1 is the perspective view showing the general appearance of the horizontal tube type multi-thread chain stitch sewing machine according to the embodiment of the present invention. FIGS. 2 and 3 are the perspective views showing the structure of the main parts of the seam ravel preventing apparatus included in the horizontal tube type multi-thread chain stitch sewing machine according to the present invention. FIG. 4 is the plan view showing the structure of the main parts of the seam ravel preventing apparatus. The following description is made using terms “left,”“right,”“forward,” and “backward” indicated by arrows in FIGS. 2 to 4. That is, the term “forward” denotes the side near a sewing operator. The term “backward” denotes the side away from the sewing operator. The terms “left” and “right” denote the left and right, viewed from the front near the sewing operat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com